A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U L Y / A U G U S T 2 0 1 6

2 4

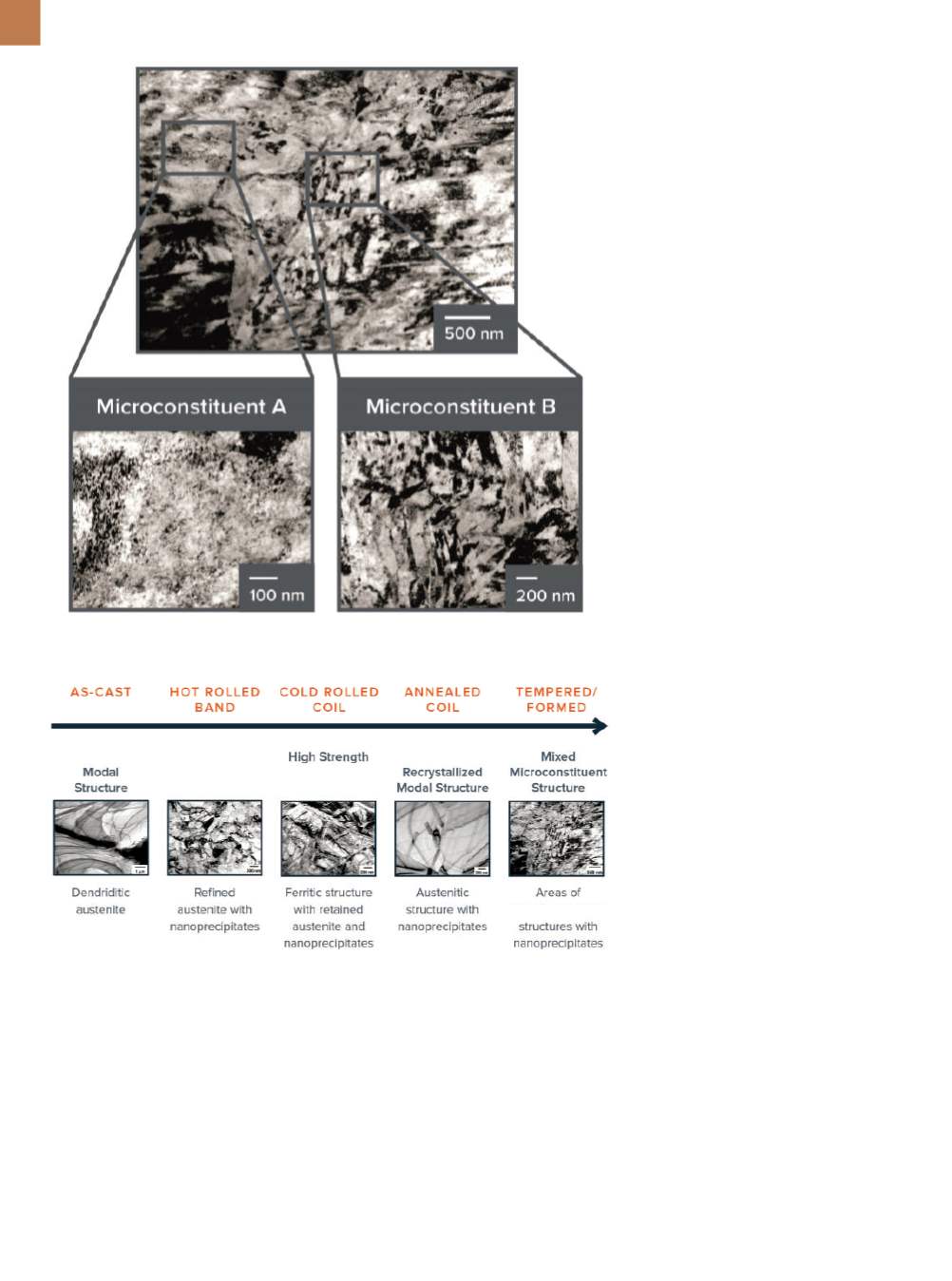

Mixed microconstituent structure

formation occurs during steel manufac-

turing and also during the automotive

part manufacturing process—stamp-

ing, roll forming, or hydroforming.

Microconstituents generated during

deformation provide high formability

to achieve complex shapes as well as

high strength.

The complete microstructural

pathway of this new sheet steel alloy—

from the as-cast modal structure to

the final mixed microconstituent struc-

ture—occurs through typical com-

mercial sheet steel processing steps

and does not require additional meth-

ods such as rapid solidification or

quenching.

CONCLUSION

Aggressive fuel economy regula-

tions including U.S. Corporate Aver-

age Fuel Economy (CAFE) standards

have spurred the automotive market

to incorporate alternative materials

such as aluminum and composites

and create clear targets for third gen-

eration AHSS to meet the industry’s

lightweighting goals. By effectively

mitigating the historical paradox

between strength and ductility, Nano-

Steel’s alloy design pathway enables a

new family of automotive sheet steel

to meet these requirements. These

new steels are expected to offer auto-

makers affordable structural design

options that can substantially reduce

vehicle weight for more fuel efficient

cars and trucks.

For more information:

Daniel J. Brana-

gan is chief technology officer, Nano

Steel, 272 W. Exchange St., Suite 300,

Providence, RI 02903, 401.270.3549,

dbranagan@nanosteelco.com,www.

nanosteelco.com.

References:

1. D.J. Branagan, et al., “3rd Generation

AHSS: From Promise to Reality,” Invited

talk, MS&T, October 4-8, Columbus,

Ohio, 2015.

Fig. 5 —

Targetedmixedmicroconstituent structure in Alloy 1, leading to third generation AHSS

with novel properties.

Fig. 6 —

Alloy 1 structural development through the major steel processing stages leading to

the final third generation AHSS structure.

design. On an industrial scale, anneal-

ing can be either continuous or batch.

This heat treatment results in alloy

recrystallization, which removes cold-

work effects andprovides a phase trans-

formation of ferrite back to austenite.

When the recrystallized sheet structure

deforms, the targeted mixed microcon-

stituent structure is formed, resulting

in the desired combination of tensile

strength at ~1200 MPa with elongation

above 45%.

Nanomodal

Struture

austenitic and ferritic

Nanomodal

Struture