A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

6

MARKET SPOTLIGHT

FEEDBACK

METAL FINISHING MARKET CONTINUES GROWTH

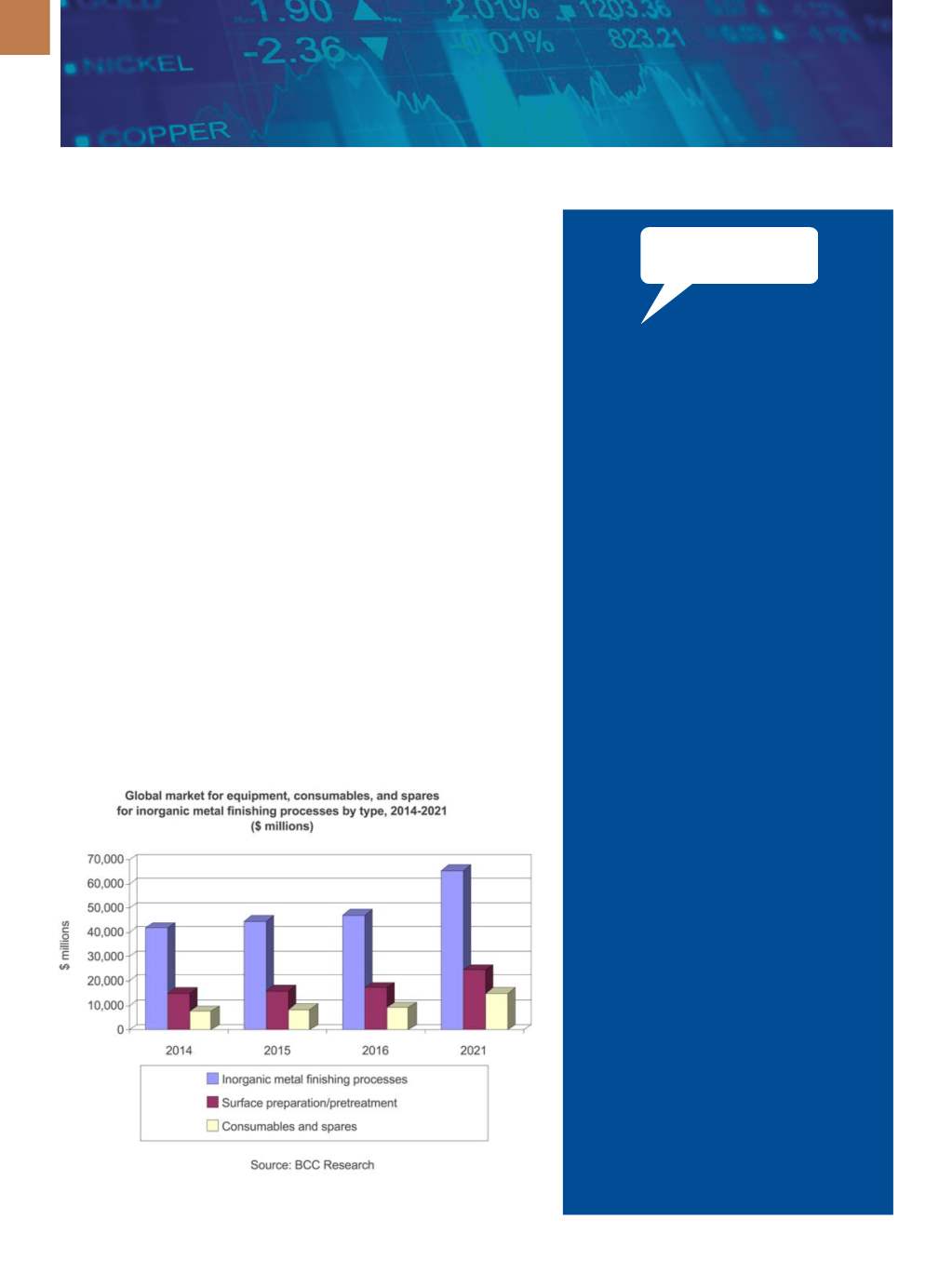

According to a new report

from BCC Research, Wellesley,

Mass., the world market for equip-

ment, consumables, and spares

for inorganic metal finishing pro-

cesses was valued at $64.5 billion

in 2014 and is expected to reach

$68.9 billion in 2015. The market

is further expected to increase at a

compound annual growth rate of

7.4% from $73.6 billion in 2016 to

$105 billion in 2021. Metal finish-

ing is defined as the deposition of

a coating, which may be metallic

or nonmetallic, onto a metallic

substrate. The market compris-

es surface preparation/pretreat-

ment, inorganic metal finishing,

and consumables and spares.

Worldwide activity in the en-

ergy production, transportation,

and storage sectors is a key driver

of increased sales formajor compa-

nies involved in this market. Major

projects related to the production

and transportation of energy, in-

cluding traditional and alternative

power generation facilities, oil and

gas drilling, pipelines, infrastruc-

ture construction, and shipbuild-

ing are under way in all areas of

the world, with a specific focus on

emerging markets including the

Middle East, Russia, Latin America,

Asia-Pacific, and Eastern Europe.

Global Markets and Technol-

ogies for Inorganic Metal Finishing

Processes

examines global and re-

gional markets for various types of

inorganic metal finishing technol-

ogies. Market dynamics, growth

drivers, inhibitors, opportunities,

and forecasts of trends and rev-

enue through 2021 are provid-

ed.

For more information, visit

bccresearch.com.

RESPECT THE TECHS

Thank you for the recent news about NASA’s

progress on welding the Orion crewmodule at

the Michoud Assembly Facility (

AM&P eNews,

Sept. 16).

In the article, the word

engineers

is

used in two places where

technicians

is more

accurate. The first sentence says that “engineers

have welded together the first two segments

of the Orion crewmodule,” but in truth the

welding was done by highly skilled and certified

technicians, as the last paragraph states.

In the engineering world, we

engineers

sometimes get credit for things we did not do at

the expense of those who did, the

technicians

.

Semantics for sure, yet there is a bias—ever

for the engineer—with the lowly technician an

afterthought. In America today, we tend to favor

education and book smarts. Our schools have

abandoned the old idea of trade school, where

a technician’s natural gifts are nurtured as a

hands-on trade.

There is little cultural respect for the plumb-

er, electrician, or welder although they are the

craftsmen, artisans, and doers of what needs to

be done. I hope ASMwill consider this and begin

to breathe respect into your readers’ minds

that to be a technician is to be an artisan, a vital

member of the engineering team, not optional

or easily interchanged—valid in their own right.

The engineer-technician skillset represents

the knowing-doing capability. If wisdom is our

guide, we must honor our intelligent, hands-on

doers as much as our intelligent, conceptual

knowers. In the Venn diagramwhere a techni-

cian’s smarts overlap with an engineer’s smarts

lies a sweet spot—where getting the job done,

and done right, makes the world a better place.

Dan Keenan

We welcome all comments

and suggestions. Send letters to

frances.richards@asminternational.org.