A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

1 0

TESTING | CHARACTERIZATION

ELIMINATING METAL DEFECTS

WITH CYCLIC LOADING

Researchers from Massachusetts

Institute of Technology, Carnegie Mel-

lon University, Xi’an Jiaotong Univer-

sity, and elsewhere have found that

under certain conditions, repeated

stretching of nanoscale metal pieces

can actually strengthen a material by

eliminating defects in its crystalline

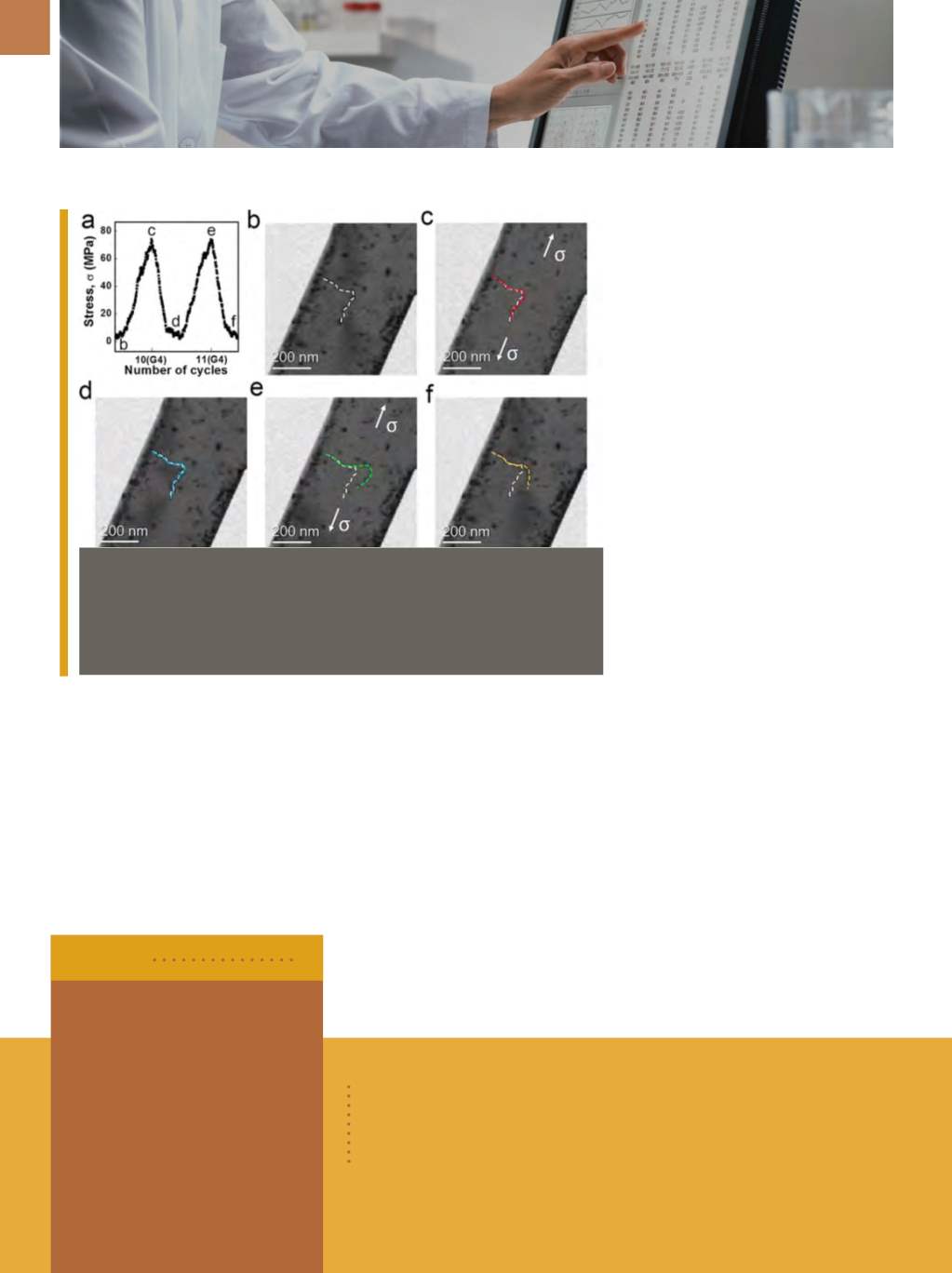

Abrupt depinning and destabilization of a line defect due to repeated cyclic loading;

(a) the evolution of nominal tensile stress during two loading and unloading cycles;

(b) to (f) are still frames from a video that correspond to the stress state marked

in (a), where white dashed lines indicate the original defect location, and colored

dashed lines represent the altered locations from cyclic loading. Direction of tensile

stretching is indicated by arrows in (c) and (e).

cyclic deformation, rather than heat-

based annealing.

Repeated small displacements

of metal tend to dislodge dislocations

from their pinned locations inside the

crystal. The small crystal has a high sur-

face-to-volume ratio, so dislocations are

attracted to the surface, and the energy

stored in the metal due to the presence

of the defects could be reduced.

By “shaking” the dislocations

gently and repeatedly, researchers

were able to get the material relatively

free of them, increasing the material’s

strength significantly. This phenom-

enon is counterintuitive, because it is

the opposite of what one sees in much

larger metal crystals, where repeated

stretching often increases defect

density and causes cracks to form.

Researchers believe the process could

help in the production of strong parts

for nanotechnology applications, such

as mechanical nanosensors, nanoelec-

tromechanical systems, and nanoro-

bots.

web.mit.edu,

cme.edu.

BROOKHAVEN HOSTS NEW

CENTER FOR COMPUTATIONAL

MATERIALS SCIENCES

The Department of Energy’s (DOE)

Brookhaven Lab, Upton, N.Y., will host

a new center devoted to developing

computational tools to advance mate-

rials science. With $12 million in fund-

ing from DOE’s Office of Basic Energy

Sciences over the next four years, this

center will be led by Gabriel Kotliar of

Rutgers University and Brookhaven,

structure. The new process is referred

to as

cyclic healing.

“Whilemetal fatigue has been stud-

ied at larger volumes of materials, there

has been little understanding of it at the

atomic scale,” says Ming Dao of MIT. To

remedy that, the team studied metal

fatigue using a transmission electron

microscope to observe atomic-scale

changes in defects. The primary subject

of the study was small, single-crystal

pieces of aluminum. Researchers aimed

to reduce or eliminate microstructural

imperfections—such as defects in the

crystal lattice known as dislocations—

through repeated, small-amplitude,

Bruker Corp.,

Billerica, Mass.,

will acquire

Jordan Valley Semi-

conductors Ltd.,

Israel, by the

end of 2015. Jordan Valley’s in-line

x-ray metrology products comple-

ment Bruker’s portfolio of analyti-

cal x-ray technologies, say compa-

ny sources.

bruker.com.

BRIEFS

Boise State University,

Idaho, will receive a $25 million gift from the

Micron Foundation.

It is the largest gift in the university’s history, and

will fund the establishment of the new Micron Center for Materials

Research, operated by the College of Engineering.

go.boisestate.edu.