A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

8

METALS | POLYMERS | CERAMICS

um, in the high-performance glass for-

mation process. Sodium and potassium

ions are typically added into the com-

position of glasses as their presence

lowers the temperature needed to form

glass, thereby saving energy. However,

this process and combination of ions

with different atomic sizes makes glass

susceptible to long-term deformations.

“The next step is to prescribe optimal

glass compositions that feature little, if

any, relaxation, in order to enable de-

sign of large yet stable screens,” says

Bauchy.

For more information: Mathieu

Bauchy, 310.825.9991,

bauchy@ucla.edu,

www.ucla.edu.

TEMPERATURE MAKES

PLASTIC MUSCLES WALK

Hydrogels are translucent, squishy

polymers that resemble tissues by hold-

ing large amounts of water within an

interlocked molecular network. A team

led by researchers at RIKEN, Japan, de-

veloped a way to cause these biocom-

patible materials to act like artificial

muscles that rapidly expand and con-

tract when heated and cooled. Yasuhiro

Ishida and colleagues designed a hy-

drogel whose properties differ consid-

erably from those of other hydrogels—

their thermoresponsive material can

lengthen in one direction and contract

in another without absorbing or releas-

ing water, allowing this muscle-like de-

vice to operate rapidly in an open-air

environment. The secret to this behav-

ior lies in tiny nanosheets embedded in

the hydrogel that harness electrostatic

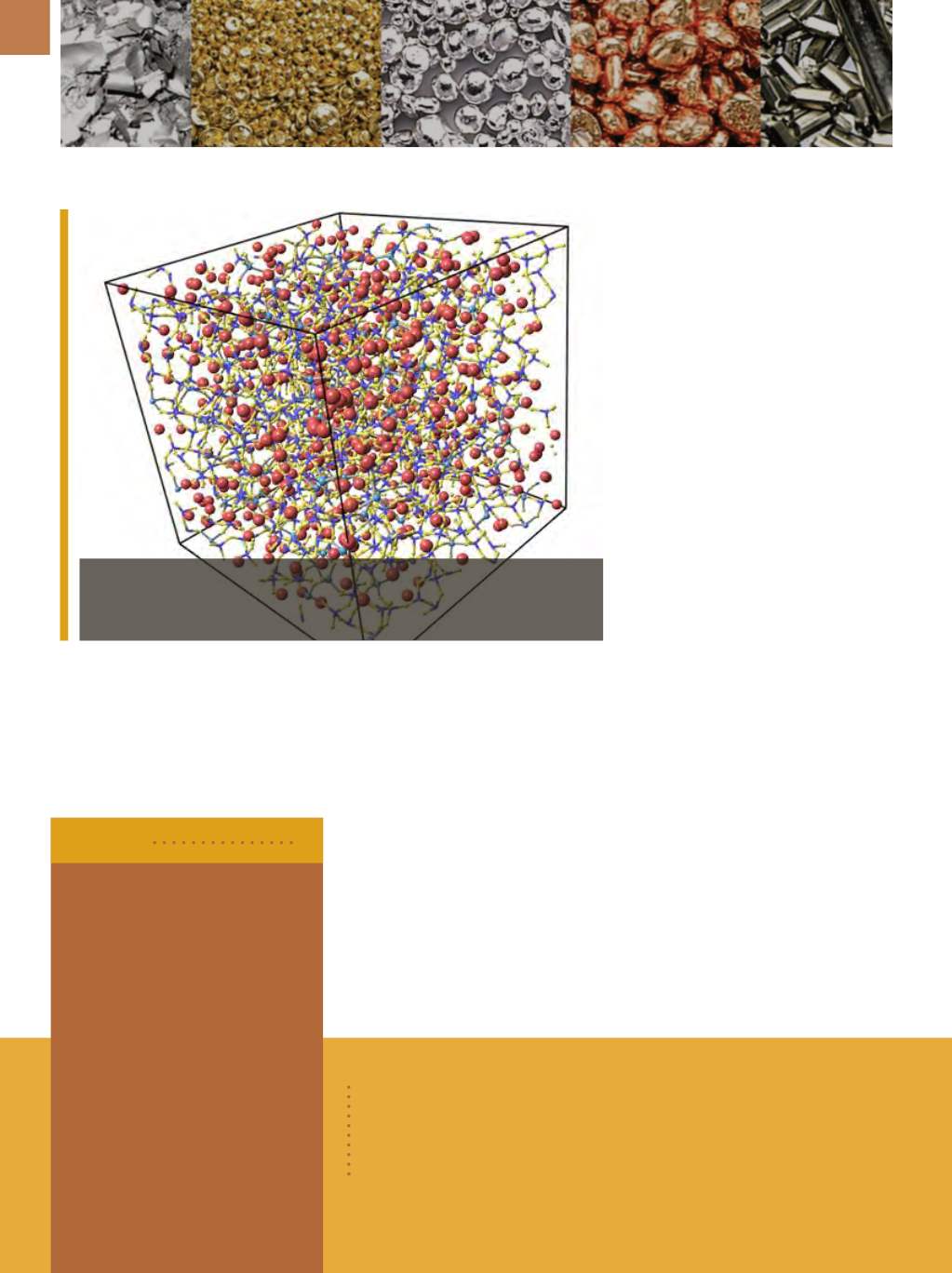

Atomic structure of a simulated sodium aluminosilicate glass, representative of

Corning Gorilla Glass. Silicon, aluminum, sodium, and oxygen atoms are represent-

ed in blue, cyan, red, and yellow, respectively. Courtesy of Mengyi Wang/UCLA.

Royal DSM,

the Netherlands,

highlighted developments in

fiber visualization and low-profile

characteristics of its Dyneema

Purity fiber for use in the design of

medical devices at the 7th Interna-

tional UHMWPE Meeting in October

in Philadelphia. Medical-grade

UHMWPE fibers enable multiple su-

ture designs, assisting surgeons in

differentiating sutures when there

are multiple styles used during a

procedure.

dsm.com.

BRIEFS

Japanese auto supplier

Yorozu Corp.

will build a $100 million metal

stamping facility in Jasper, Ala., creating 300 jobs. The facility will provide

suspensions and other components to several auto assembly plants. Con-

struction is expected to start by January 2016, with operations beginning

in July 2017.

www.yorozu-corp.co.jp/en.GLASS FLOW DISCOVERY

ENABLES LARGER

SMART SCREENS

In complex, high-tech kinds of

glass, like Corning Gorilla Glass, suscep-

tibility to room-temperature deforma-

tions has been known to exist for years.

Now, researchers from the University of

California, Los Angeles discovered why

such flowing happens and how fast.

Using molecular dynamics simulations

of different glasses, researchers show

that high-performance glass can exhibit

some long-term deformations propor-

tional to how large the glass is.

“We found that this long-term

relaxation is due to the coexistence

of competitive chemical elements of

different sizes in the atomic network

of the glass, which is known as the

mixed-alkali effect,” says UCLA profes-

sor Mathieu Bauchy. The key is the use

of two alkali ions, sodium and potassi-