2 5

TRANSPARENT POLYCRYSTALLINE

MATERIALS RESIST BULLETS

Capable of stopping 50-caliber, armor-piercing rounds, ALON

and Spinel are hard and durable transparent polycrystalline

materials manufactured using powder based processes.

Mohan Ramisetty, Suri Sastri, FASM*,

Surmet Corp., Burlington, Mass.

A

new class of advanced polycrys-

talline materials with a cubic

crystal structure—including alu-

minum oxynitride (ALON) and magne-

sium aluminate (Spinel)—is making its

way into many advanced applications.

Due to their unique combination of me-

chanical, optical, and chemical prop-

erties, along with recent advances in

manufacturing, these materials are

now being used for critical defense, in-

dustrial, and civilian applications.

ALON has attracted consider-

able media attention lately, based on

its ability to stop 50-caliber armor-

piercing rounds, coupled with night vi-

sion capability, and crystal clear trans-

parency. Sometimes referredtoas “trans-

parent aluminum,” the material appears

regularly in movies, documentaries, and

*Member of ASM International

TABLE 1 —KEY PROPERTIES OF ALON AND SPINEL

[1,2,3]

Property

ALON

Spinel

Chemical formula (nominal)

Al

23−1/3X

O

27+X

N

5−X

MgAl

2

O

4

Crystal structure

Cubic, spinel

Cubic, spinel

Lattice parameter/constant (nm)

0.794-0.796

0.8085

Density (g/cc)

3.69

3.58

Strength (MPa)

300-700

70-300

Hardness (kg/mm2, Knoop)

1800-1870

1550-1650

Young’s modulus (GPa)

323

277

Refractive index (at wavelength 0.5 µm)

1.80

1.723

Transmission wavelength range

(at 2 mm thick)*

0.25 to 6

0.25 to 6.5

Refractive index in-homogeneity

(~4" aperture, RMS)

~5

<10

Transmittance in the visible

(no AR coating)* (%)

84-85

80-86

Haze* (%)

<2

<10

Clarity* (%)

>98

>95

*Varies depending on processing conditions and thickness.

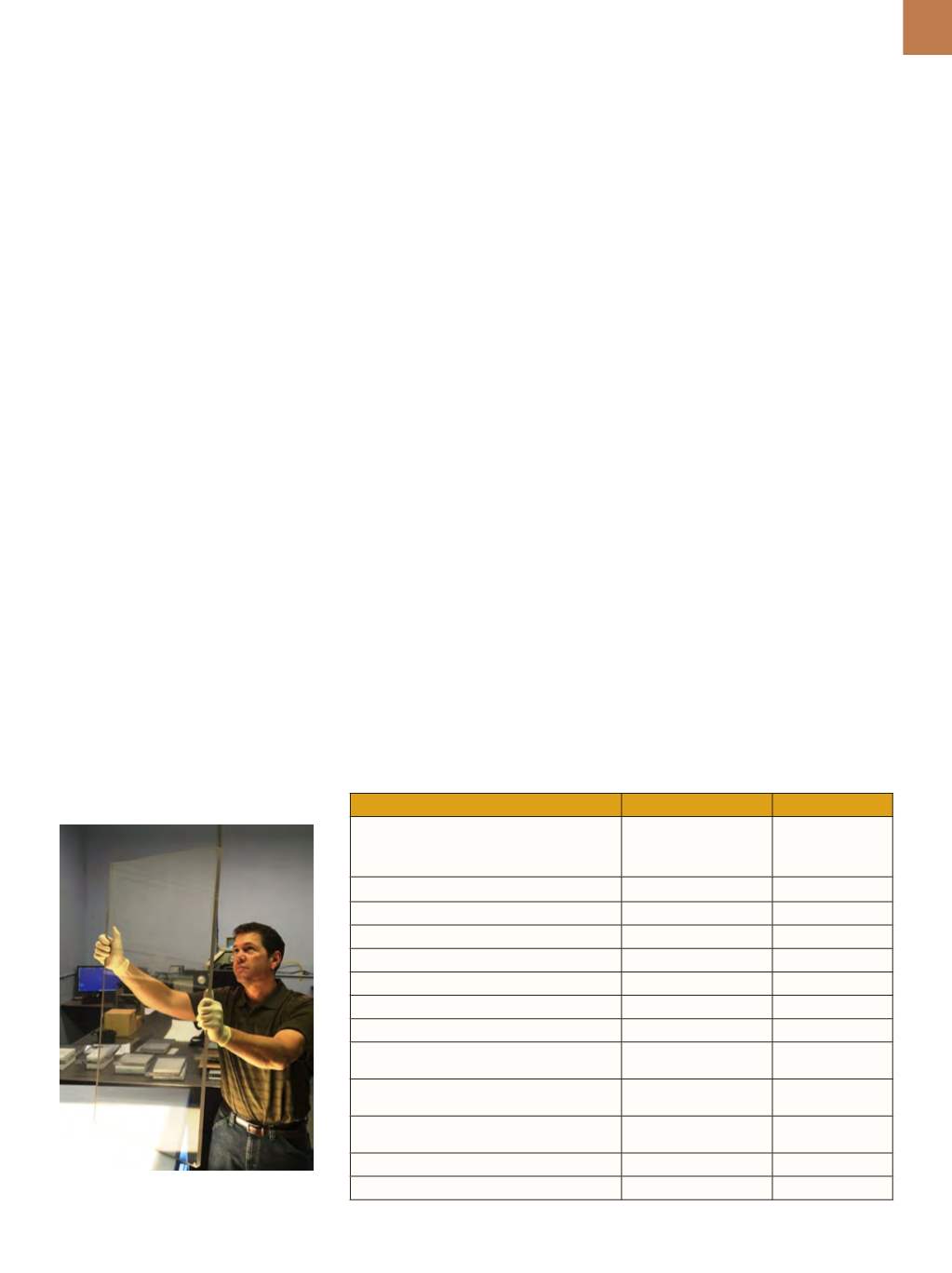

Fig. 1 —

Engineer inspects a 19 × 36 in.

ALON window.

popular fiction. For example, the movie

Jurassic World

used ALON for its gyro-

spheres, ALON Armor was featured in an

episode of Discovery Channel’s

How Stuff

Works,

and the material also appeared in

Lee Child’s best-selling novel

Personal.

CHEMISTRY AND PROPERTIES

Although both ALON and Spinel

exhibit a cubic spinel crystal struc-

ture, the lattice constants and chemi-

cal bonds vary and result in significant

property differences. Table 1 summariz-

es the key properties of these materials.

ALON is significantly harder and

stronger than Spinel, primarily due to

the slightly increased covalent nature

of its bonding versus a predominantly

ionic bond in Spinel. ALON is the hard-

est transparent polycrystalline ma-

terial available for commercial use

[1]

.

Compared to ALON, Spinel’s lattice

structure features a slightly expand-

ed unit cell and transmits further into

the mid-wave infrared (MWIR) region

(Fig. 2), making it desirable in many

midwave infrared sensor applications.

MANUFACTURING PROCESSES

AND CHALLENGES

Manufacturing both ALON and Spi-

nel involves many of the steps required

to make any technical ceramic mate-

rial. However, attaining crystal-clear

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 5