A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

2 8

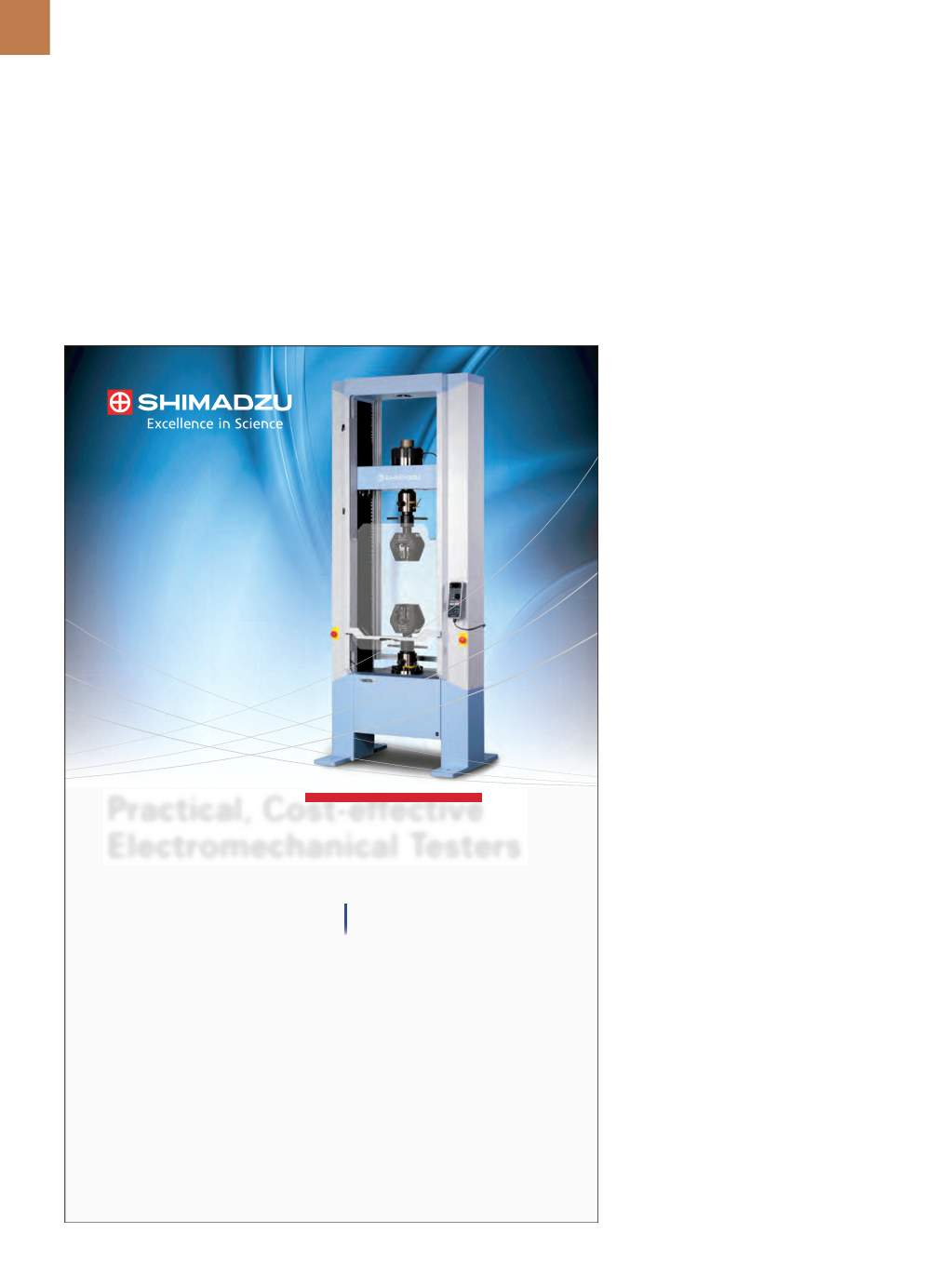

Combining advanced specifications with an affordable, modern design, Shimadzu’s AGS-X Series of floor and tabletop universal testers delivers practical solutions across a wide range of applications. By incorporating multiple control options, load cells with maximum capacities from 1 N to 300 kN, and the utmost in safety considerations, the AGS-X series is the choice for easier, more efficient testing . Shimadzu’s AGS-X Series features: ■ Accurate stress-strain curves with Class 0.5 load cells ■ High-speed data sampling up to 1 msec (1 kHz) ■ Precise stress- and strain-controlled testing ■ Comprehensive safety measures ■ Easy-to-use software with a refined user interface for more efficient, effective testing Shimadzu Scientific Instruments Inc., 7102 Riverwood Dr., Columbia, MD 21046, USA Learn more. Call (800) 477-1227 or visit us online at www.ssi.shimadzu.com/AGSX Practical, Cost-effective Electromechanical Testers In addition, a comprehensive selection of grips, compression plates, jigs, extensometers, and other accessories allow configurations to be tailored to almost any application. Adaptable to Countless Applicationsfractured surface of conventionally hot

pressed Spinel with LiF doping.

Surmet uses a different approach,

which includes solid-state pressureless

sintering followed by hot isostatic press-

ing (HIP). This method is not without

challenges, but the overall result is me-

chanically superior and more reliable

onmany counts than hot pressed Spinel

(Fig. 4). Pressureless sintering followed

by HIP is also used to produce ALON.

CURRENT AND

POTENTIAL USES

Both ALON and Spinel have enor-

mous potential in a broad range of

applications. However, ALON appears

to be at the forefront primarily due to

its robustness and superior properties

in addition to large-scale and reliable

manufacturability. Table 2 summarizes

some of the key properties and applica-

tions for ALON and Spinel although the

majority of the list is mainly applicable

to ALON.

COMMERCIALIZATION AND

FUTURE APPLICATIONS

Scaling up ALON manufacturing

from laboratory to production quantities

has required more than a decade of ded-

icated process development and tens of

millions of dollars. Work is now under-

way to bring down the cost so that these

materials can find a role in cost-sensitive

applications such as consumer products,

semiconductor equipment, and ener-

gy-related uses. ALON is now available

in large sizes (up to 18 × 35 in.) and large

quantities. Spinel remainsawork inprog-

ress. For its efforts, Surmet was recently

awarded the American Ceramic Society’s

Corporate Technical Achievement Award

in 2013. Surmet acknowledges funding

support from the U.S. Department of De-

fense in this effort.

~AM&P

For more information:

Mohan Rami-

setty is a materials engineer, Surmet

Corp., 31 B St., Burlington, MA 01803,

781.345.5742,

mramisetty@surmet.com,

www.surmet.com.

Acknowledgments

The authors acknowledge Santosh

Jha, Lee Goldman, Uday Kashalikar, Mark

Smith, Cindy Gunda, and the entire Sur-

met team for their valuable contributions

and helpful discussions in preparing this

article.

References

1. M. Ramisetty, et al., Transparent

Polycrystalline Cubic Spinels Protect

and Defend,

Am. Ceram. Soc. Bull.

, Vol

92, 2, p 20-24, 2013.

2. D.C. Harris, Durable 3-5

μ

m Trans-

mitting Infrared Window Materials,

In-

frared Phys. Technol.

, Vol 39, p 185–201,

1998.

3. L.M. Goldman, et al., ALON Optical

Ceramic Transparencies for Window,

Dome and Transparent Armor Applica-

tions, Proc. SPIE 8016, 801608, 2011.

4. M. Rubat du Merac, et al., Effect of Im-

purities and LiF Additive in Hot-Pressed

Transparent Magnesium Aluminate

Spinel,

Int. J. Appl. Ceram. Technol.

, Vol

10, E33–E48 (2012); doi: 10.1111/j.1744-

7402.2012.02828.x (2012).