A D V A N C E D M A T E R I A L S & P R O C E S S E S | N O V E M B E R / D E C E M B E R 2 0 1 5

2 6

transparency presents several chal-

lenges that require additional critical

steps. Certain physical and chemical

requirements must be met in order to

achieve full transparency. For example,

transparent materials cannot have any

features that are large enough to scat-

ter light in the wavelengths of interest,

mainly in the visible range. Some of

these requirements include:

1. >99.9% density—Porosity that is

larger than roughly 40 nm causes

light to scatter.

2. Ultra high purity—The presence of

impurities, such as a few ppm of

transition metals, imparts color or

tint into the part.

3. Clean microstructure—No secondary

phases at the grain boundaries.

Microstructural defects such as pores

or bubbles also result in inclusions.

To get an idea of the difficulty of

achieving these requirements for ce-

ramics, first consider a powder metal-

lurgy example: Imagine starting with

micron to submicron size metal or alloy

powder, compacting it into a shape,

and then heat treating it to nearly full

density with absolutely no microstruc-

tural defects on the scale of tens of

nanometers. This is quite challenging

even for metals, in which plastic defor-

mation takes place and less complex

chemistries and diffusion mechanisms

are involved. In addition, much lower

sintering temperatures are needed for

metals versus ceramics. The process is

orders of magnitude more complex for

transparent ceramic materials, requir-

ing tens of millions of dollars and more

than a decade of effort to transform it

from a laboratory invention into a via-

ble commercial product.

Figure 3 depicts the key steps in-

volved in transparent ceramics manu-

facturing. In any powder-based meth-

od, a robust process begins with a

consistent and reliable powder supply

with the appropriate characteristics.

The manufacturing process for ALON

is reliable and repeatable, so it can be

produced with consistently higher qual-

ity and in larger quantities and larger

sizes than Spinel.

One of the contributing factors to

ALON’s robust manufacturing process

is that Surmet Corp. synthesizes its

own powder with consistent charac-

teristics. In contrast, Spinel powder is

sourced from an outside supplier and

exhibits inconsistent quality and reli-

ability, which has inhibited its progress

in terms of reproducibility and scalabil-

ity. Although Spinel has been available

for nearly 50 years, manufacturers still

struggle to consistently produce parts

as small as 12 × 12 in. with reasonable

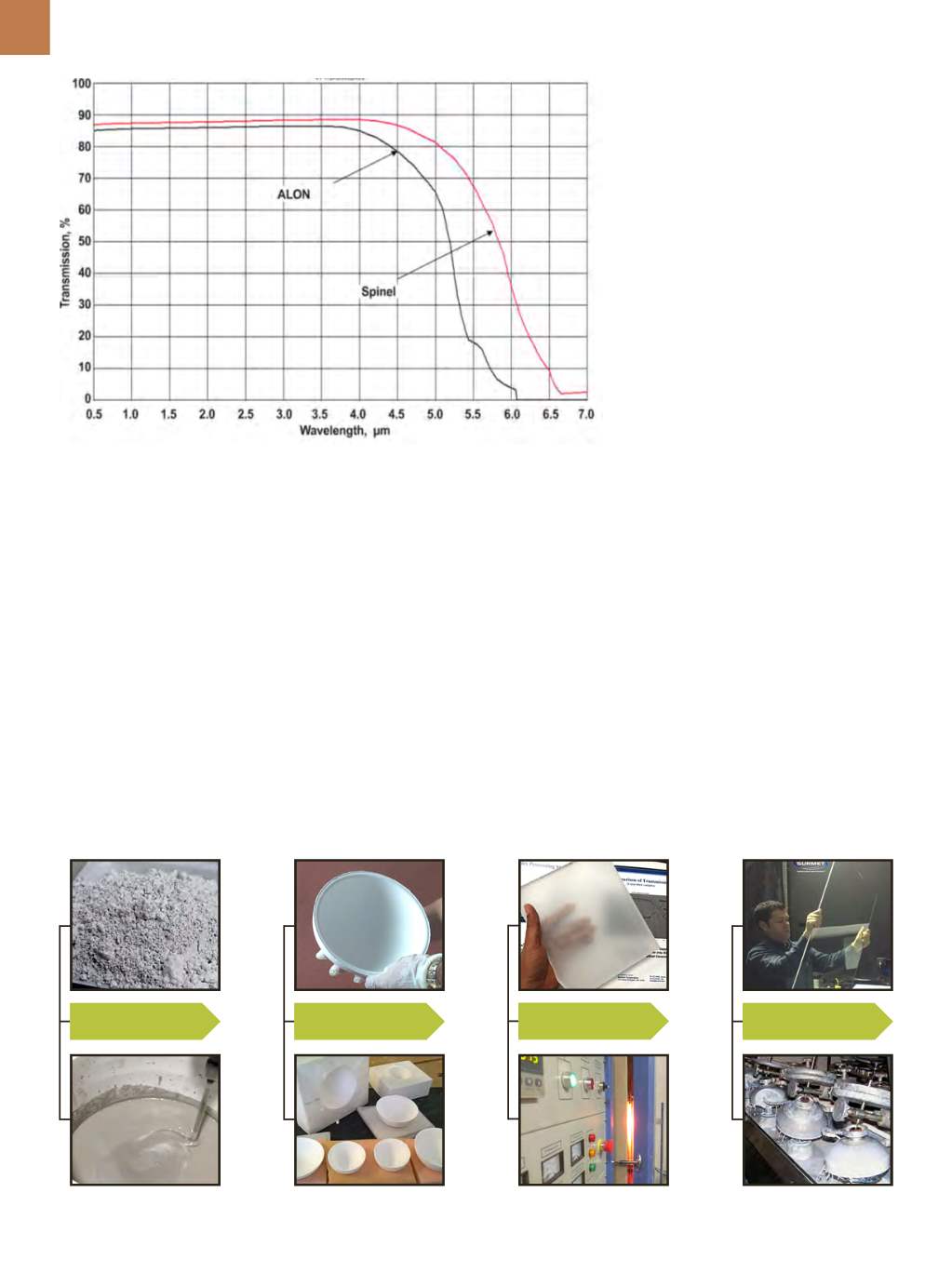

Fig. 2 —

Transmission spectra of ALON and Spinel; 2-mm-thick sample with no anti-reflection

coatings.

Fig. 3 —

Key steps in manufacturing transparent polycrystalline ceramics.

Powder preparation

Greenware formation

Grinding and

polishing

Densification/

heat treatment