A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 5

2 3

One testing trend in plastics de-

sign is to subject sample material to

extreme conditions. For example, when

researching roof shingles made of recy-

cled material, mechanical properties

such as flame retardancy and impact

resilience must withstand extreme heat

and hurricane-force winds. Another ex-

ample Malloy cites is snap-in hubcaps.

“The material must be tested accord-

ing to cold day driving, such as at -40°F,

versus the temperature specified in the

ASTM standard,” he explains. “In plas-

tics, this type of testing is increasing in

both volume and sophistication. Test-

ing is key to answering the ‘will it work’

question. There is only somuch one can

do with theories.”

3

INNOVATIVE BUILDING

MATERIALS

“In civil engineering, anything

that is expected to take any reason-

able level of stress and strain or be

subjected to elevated temperatures or

to a lot of moisture needs to be test-

ed and characterized,” says Jerome

(Jerry)

Hajjar, chair of Northeastern

University’s department of civil and en-

vironmental engineering. The school’s

Structural Testing of Resilient and Sus-

tainable Systems (STReSS) lab focuses

on the security and sustainability of

structures against hazards and events,

whether manmade or natural. Among

the lab’s current projects is the devel-

opment of deconstructable systems for

sustainable steel structures to create

reusable building materials. STReSS

Lab conducts large or full-scale compo-

nent tests of clamping connections and

experimental tests of deconstructable

composite floor systems subjected to

gravity and lateral loading. The team

is also researching foam materials that

can be used in a cladding system to

harness and store energy from the sun

or wind.

“One of the challenges in civil en-

gineering is that while engineers de-

sign structures not to collapse in major

events, we’re not very good at mim-

icking collapse in simulated environ-

ments,” says Hajjar. Whereas tension or

shear failures can be quantified using

standard test procedures, multiple forc-

es are at play during a major event such

as an earthquake or tsunami. Helping

to meet this challenge is the profes-

sion’s increasing capability to simulate

at the atomic and molecular level.

The more microscopic the under-

standing of how a material behaves,

the greater likelihood engineers can

design new materials and associated

structural systems capable of with-

standing extreme loads. One example is

Hajjar’s research into using replaceable

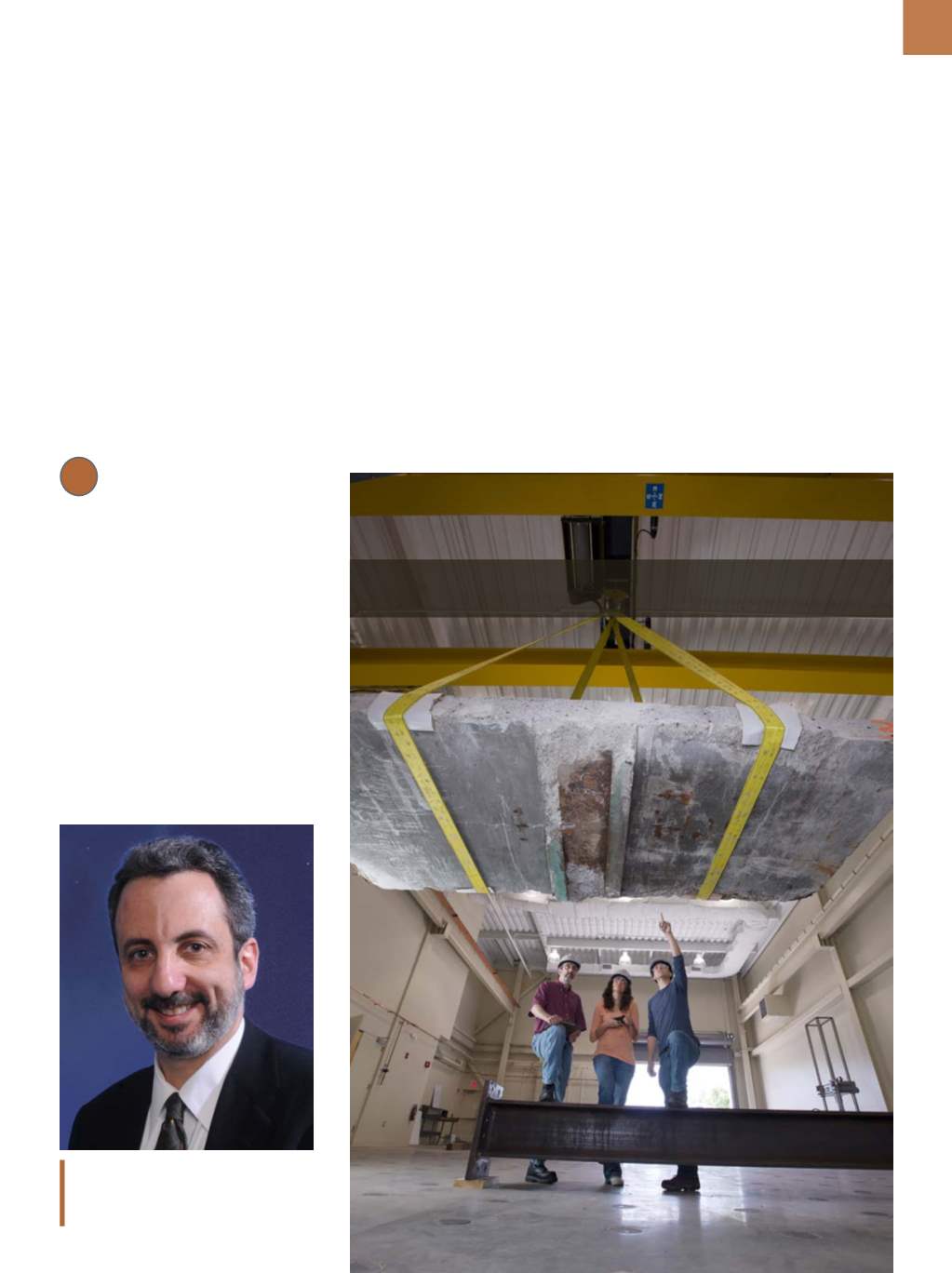

Jerome Hajjar, civil and environmental

engineering department chair, Northeast-

ern University.

Professor Jerome Hajjar of Northeastern University, left, confers with students during a

materials test.