AUTOMATION ADVANTAGES

Automated solutions offer vari-

ous levels of benefits and often do not

require a full robotic testing system.

This is known as the

automation con-

tinuum.

This continuum offers phases

of automation and allows laboratories

to automate parts of their testing pro-

cess, usually starting with their greatest

pain point such as data entry. By adding

barcode labeling and a barcode reader,

all the necessary batch and sample in-

formation can be loaded into a testing

system or LIMS by simply scanning a

barcode. Not only does this decrease

variability, it frees up valuable opera-

tor time to perform other tasks and re-

quires no special training (Fig. 3).

Another challenge that can be

easily automated is specimen measure-

ment. Automating measurements can

be as simple as changing fromamanual

micrometer to a digital micrometer on

a stand (Fig. 4). The specimen is load-

ed into the micrometer mounted on a

stand. The red upload button on the mi-

crometer is pressed and the measure-

ment value is automatically loaded into

the testing software. If further automa-

tion is desired, an automated measure-

ment device that can measure width

and thickness at the same time can also

be used (Fig. 5). With this solution, the

specimen is loaded into a device that

measures both width and thickness and

then automatically loads the values

into the testing software. If multiple

measurements are desired, the auto-

matic device can store separate values

and then transfer the desired measure-

ment value into the testing software.

This also saves valuable operator time

and reduces variability.

Moving through the typical testing

sequence, the next step is extensometer

attachment. This can be especially time

consuming and requires a lot of skill

and concentration to attach properly.

By adding an automatic extensometer,

setup time is reduced because the au-

tomatic extensometer sets the desired

gauge length (Fig. 6). Results variability

is decreased, as the extensometer auto-

matically attaches properly to the spec-

imen and in the same location for every

sample. Lastly, using an automatic ex-

tensometer improves operator safety

as less time is spent in the testing area,

minimizing physical fatigue.

CASE STUDY

During a side-by-side experi-

ment that compares the benefits of

a semi-automated test setup to a

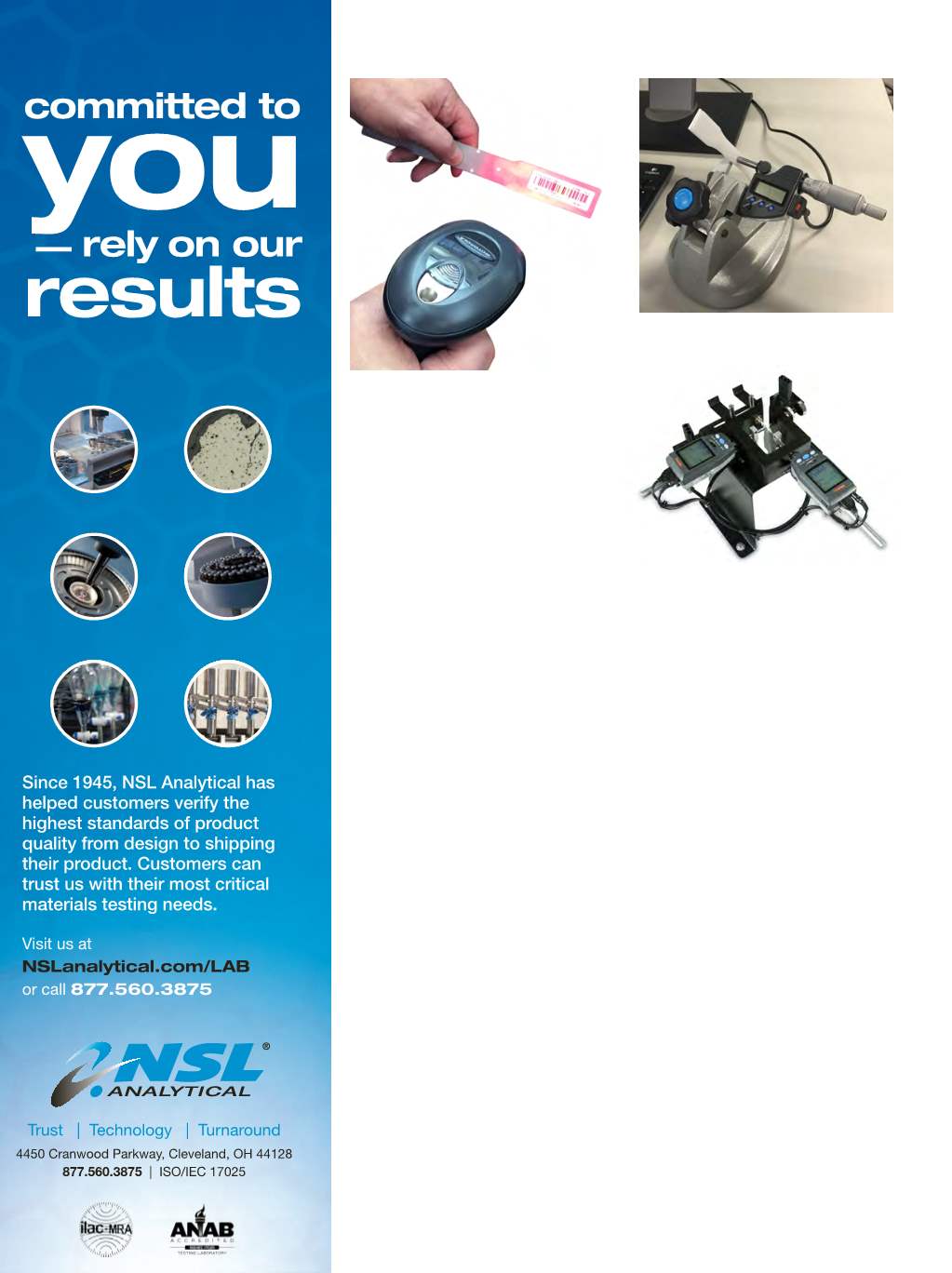

Fig. 3 —

Barcode labeling and a barcode

reader allow necessary batch and sample in-

formation to be loaded into a testing system

or LIMS by scanning a barcode.

Fig. 4 —

Digital micrometer on a stand.

Fig. 5 —

An automatedmeasurement

device measures width and thickness at the

same time.

Elemental Thermal Wet Chemistry Metallurgical Organic Optical Elemental Thermal Wet Chemistry Metallurgical Organic Optical