A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

N O V E M B E R / D E C E M B E R

2 0 1 5

1 9

A

utomation is commonly used in

everyday life. For example, au-

tomatic doors at retail stores,

car windows, ticket and toll booths,

electronic devices, and online banking

are among the many forms of automa-

tion that make life more convenient.

Despite this, there is resistance to us-

ing automation in mechanical testing

scenarios. With regard to lab automa-

tion in particular, common objections

include worries about equipment cost,

the time and difficulty of training op-

erators, and the belief that automated

systems are inflexible when changes

are required.

Despite these fears, automation of-

fers many key advantages in mechanical

testing. For example, it reduces retesting

due to data entry errors and failed tests,

resulting in quicker go/no-go decisions

for end users. Automation also offers

a better use of skilled labor. Instead of

spending time loading testing machines

or waiting for tests to finish, operators

can work on more valuable tasks. Com-

panies using automation will see an

increase in testing efficiency because it

allows testing laboratories to keep up

with increased testing demands with-

out additional personnel, as automation

can run overnight and on weekends un-

attended, increasing throughput. Auto-

mation also improves personnel safety,

reduces repetitive motion injuries, and

keeps operators clear of testing equip-

ment and moving machinery.

TABLE 1 —TYPICAL TESTING CYCLE

Step 1 Specimen ID or batch is entered by operator.

Step 2 Specimen is measured, usually in three places.

Step 3 Specimen information is manually entered into software.

Step 4 Specimen is loaded into grips.

Step 5 An extensometer is attached to the specimen (if necessary).

Step 6 Test is initiated by operator.

Step 7 Operator waits for a test to complete.

Step 8 Specimen is removed from grips.

Step 9 Operator manually transfers results to the database.

MANUAL TESTING PROCESS

Many manual and tedious steps

are involved in a typical testing cycle

(Table 1). All of these steps take valuable

operator time, and many can potential-

ly introduce errors and variability that

might create more work due to retest-

ing. Performing manual measurements

is time consuming and cumbersome,

which can lead to errors—numbers can

be written incorrectly, transposed, or

forgotten. In fact, some testing labs re-

port measurement processes consum-

ing as much as one-third of their testing

process time (Fig. 1).

Loading specimens into testing

equipment is operator-dependent and

can have a big impact on results. This

process also presents multiple oppor-

tunities for errors because specimens

can easily be loaded incorrectly—too

high, too low, off center, or at an angle.

For example, consider two operators

testing the same batch of specimens.

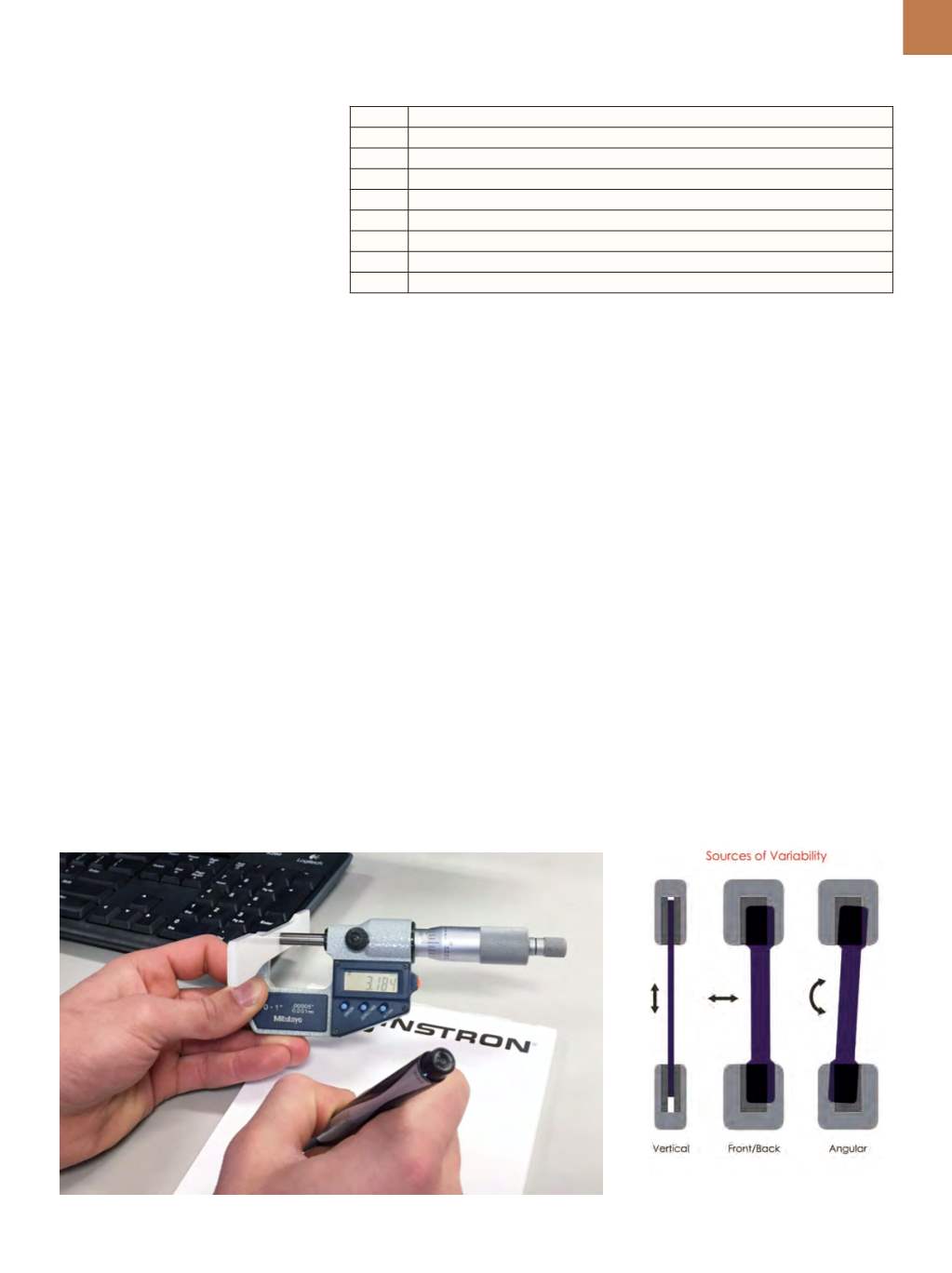

Fig. 1 —

Manual measurement performance is time consuming and often leads to errors.

Operator A tends to test on the high

side. While most of the testing stays

within the product limits, occasion-

ally results are out of range and good

product is not shipped. On the other

hand, Operator B tends to test on the

low side. Again, most of the values stay

within product limits, but occasionally,

due to lower limit testing, some prod-

uct that should actually be rejected

unfortunately passes and bad product

is shipped. It all depends on the oper-

ator’s technique, and the difference

between operators could result in both

lower quality and higher costs (Fig. 2).

One of the final steps in the testing

process, and likely the most crucial, is

transferring testing results into a LIMS

or master database for analysis, track-

ing, and to make important product

decisions. Similar to manual entry of

information at the beginning of the

testing process, manual results entry is

time consuming and increases variabil-

ity and errors.

Fig. 2 —

Loading specimens into testing

equipment can easily be done incorrectly—

too high or too low, off-center, or at an angle.