A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

5 7

17

FEATURE

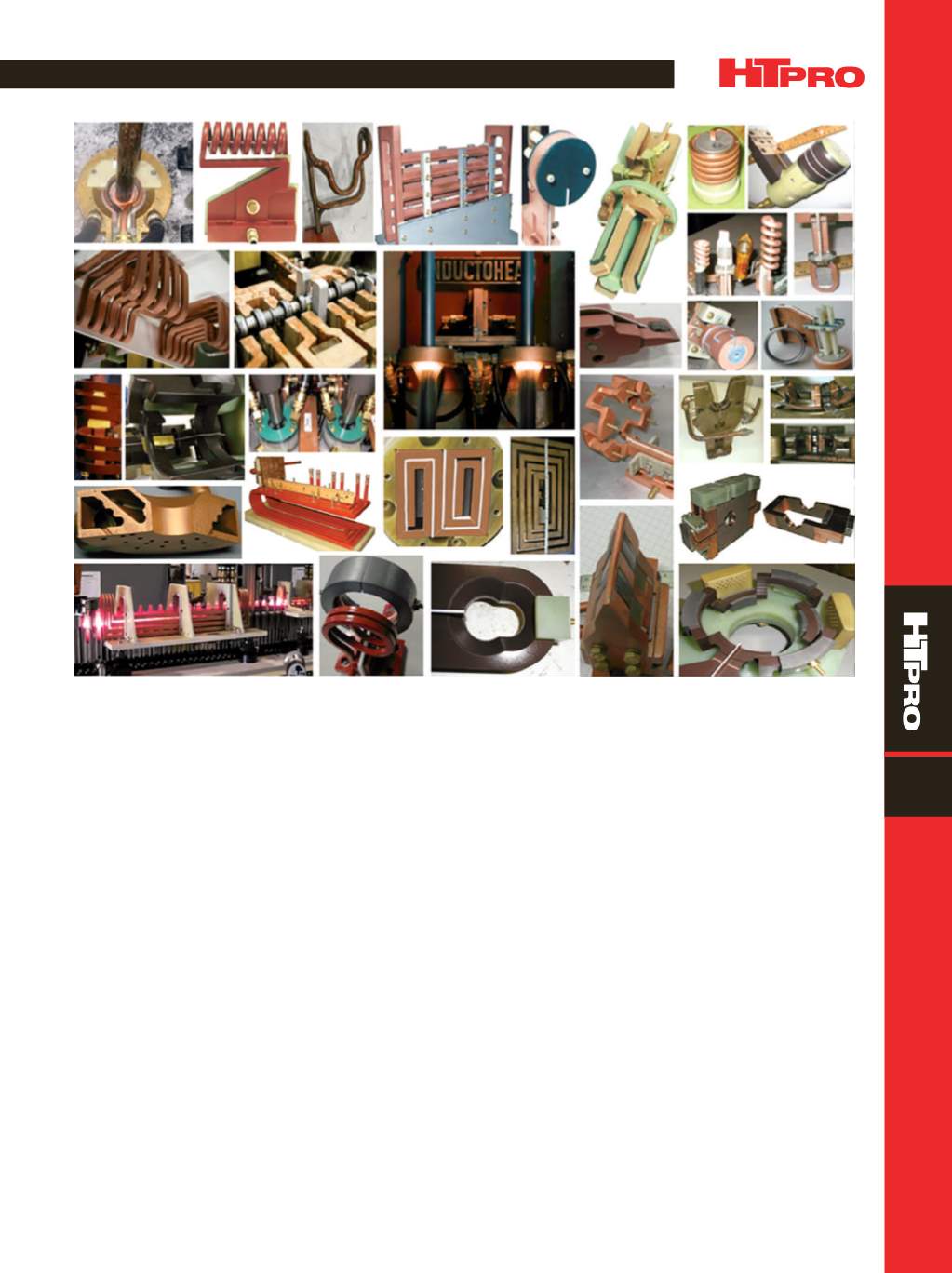

Fig. 1 —

Array of different induction coil designs.

spatial relationships, which produce inductors of the re-

quired shape and precision. Figure 2 shows a variety of fin-

ished and semifinished CNC-machined hardening inductors.

In the past, most of these inductors were fabricated by braz-

ing and banding coils. CNC machining is a superior method

to achieve accurate, robust inductors for use in automotive,

aerospace, defense and other industries where high process

repeatability is critical.

Brazing is completely eliminated with some CNC-

machined inductors, such as those used in Inductoheat’s

nonrotational SHarP-C processes for hardening crankshafts

and camshafts. Brazing is minimized in other applications,

used only to encapsulate water-cooling channels.

Some inductors, especially those used in selective

hardening, have very complex geometries. A computerized

3Dmetrology laser scanner is used to verify coil dimensional

accuracy and alignment precision within about 25 microns

(0.001 in.) after fabrication and assembly (Fig. 3).

CONVENTIONAL INDUCTORS

Steel shafts andshaft-like components areamongparts

that traditionally are induction hardened using scanning or

single-shot heat treating. With the single-shot method, nei-

ther the shaft nor coil move relative to each other; the part

typically rotates instead. The entire region to be hardened is

heated at the same time.

A single-shot inductor consists of two legs and two

crossover segments, also known as bridges or horseshoe

half-loops (Fig. 4). Crossover segments encircle only half of

the workpiece circumference, and induced eddy currents

primarily flow along the length of the part. An exception is

crossover segments where the flow of eddy current is half

circumferential. Longitudinal leg sections are profiled by

relieving selected regions of the copper to accommodate

workpiece geometrical features, such as changes in diame-

ter or irregularities. Section(s) of a single-shot inductor with

narrower heating surfaces facing the shaft increase induced

power density in desirable regions(s).

For a workpiece containing fillets, it is often necessary

to increase heat intensity in the fillet region to heat the great-

er volume ofmetal. Also, the largermetalmass in the proxim-

ity of the heated fillet and behind the region to be hardened

produces a substantial “cold sink” effect. This draws heat

from the fillet due to thermal conduction, which must be

compensated for by inducing additional heating energy in