A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

5 3

13

FEATURE

3. B. Ferguson and W. Dowling, Predictive Model and

Methodology for Heat Treatment Distortion, NCMS

Report #0383RE97, 1997.

4. T. Inoue and K. Arimoto, Development and

Implementation of CAE System “HEARTS” for Heat

Treatment Simulation Based on Metallo-Thermo

Mechanics,

J. Mater. Eng. Perform.

, Vol 6, p 51–60, 1997.

5. P. Carlone and G.S. Palazzo, Development and

Validation of a Thermo-Mechanical Finite Element Model

of the Steel Quenching Process Including Solid-Solid

Phase Changes,

Int. Appl. Mech.

, Vol 46, p 955–971, 2011.

6. M. Lusk, et al., On the Role of Kinematics in Constructing

Predictive Models of Austenite Decomposition,

Proc. of

TMS

, p 311–331, 2003.

7. D. Bammann, et al., Development of a Carburizing

and Quenching Simulation Tool: A Material Model for

Carburizing Steels Undergoing Phase Transformations,

Proc. 2nd Intl. Conf. on Quenching and Control of Distortion

,

p 367–375, 1996.

8. V. Warke, et al., FEA Model for Predicting the Response

of Powder Metallurgy Steel Components to Heat

Treatment,

Mater. Sci. Eng. A

, Vol 518(1–2), p 7–15, 2009.

9. Z. Li, et al., Data Needs for Modeling Heat Treatment of

Steel Parts,

Proc. Matls. Sci. & Tech. Conf.

, p 219–226, 2004.

For more information:

Zhichao (Charlie) Li, DANTE Solu-

tions Inc., 7261 Engle Rd., Suite 105, Cleveland, OH 44130,

charlie.li@dante-solutions.com,

www.dante-solutions.com.

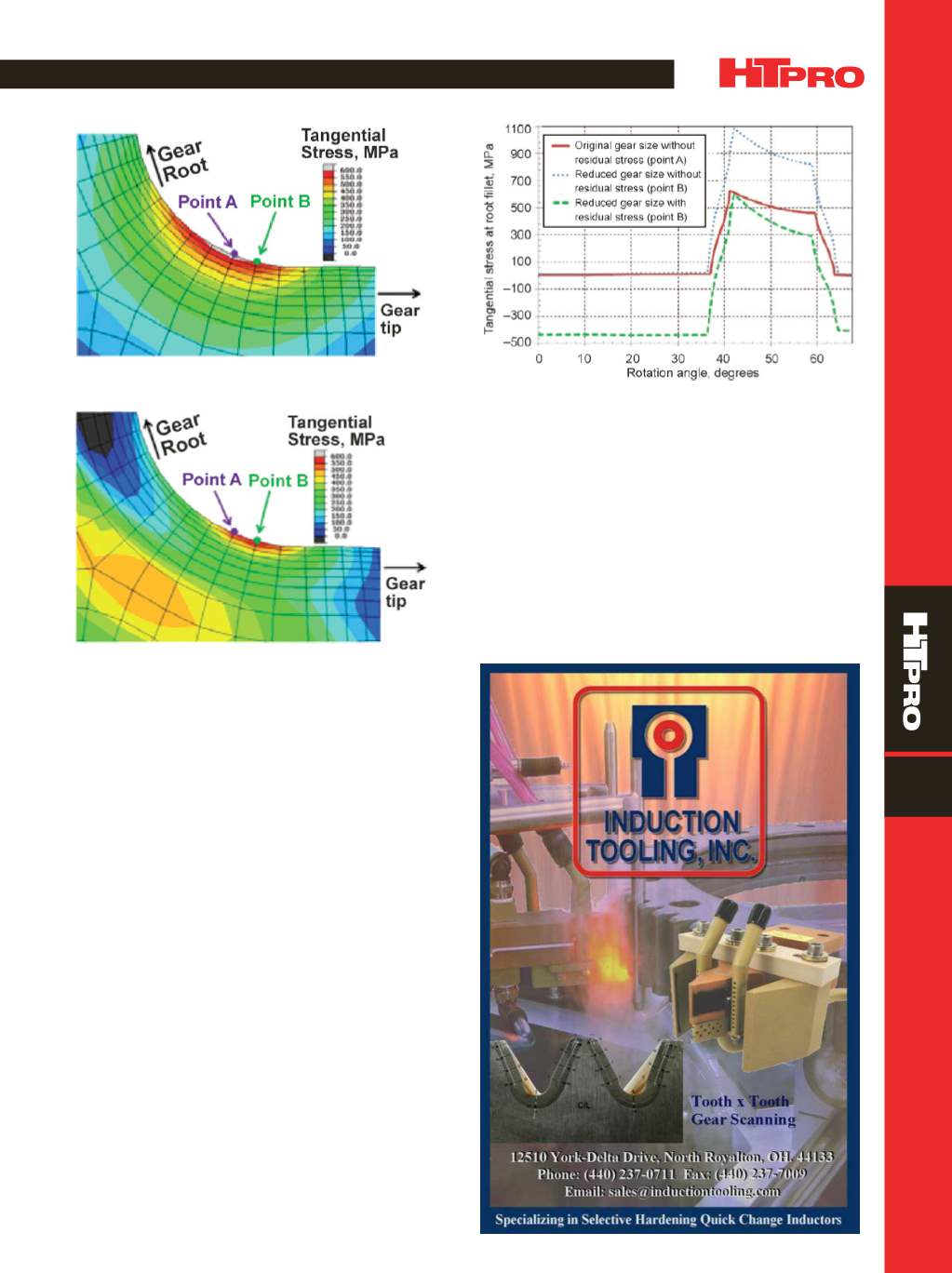

Fig. 7 —

Tangential stresses along root fillet under torsional load

of 3287 Nm. (a) Case 1—original gear size without heat treatment

residual stresses, and (b) Case 2—reduced gear size with heat

treatment residual stresses.

(a)

(b)

Fig. 8 —

Comparison of tangential stresses at root fillet during

rotation under torque load.