A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

5 1

11

FEATURE

residual stresses is negligible. It is assumed that residual

stress from heat treatment of the original size gear is zero.

To reduce gear size, a combination of carburization and

oil quench is proposed to introduce compressive residual

stresses to the gear surface for improved bending fatigue

performance. AISI 8620 alloy carburizing grade was selected

as the gear material, with a 25% reduction in the

x

-

y

plane

while keeping the same axial dimension (Fig. 2b). Gear di-

mensions are 42 mm OD, 19 mm ID, 33 mm root diameter,

and 50 mm thick. The volume or mass of the smaller gear

is 56% that of the original gear, with the centerline distance

between the gear pair reduced proportionally to 77 mm.

MODELING HEAT TREATMENT

The smaller gear is gas carburized, followed by oil

quenching and low temperature tempering. The entire gear

surface is carburized using process conditions of 925°C for

8 hours, with a carbon potential of 0.8%.

Figure 3a shows the predicted carbon-distribution

(wt% C) contour. Predicted effective case depth (ECD) is

0.75 mm, assuming 0.4 wt% carbon as the threshold of ECD

definition. After carburization, the gear is cooled to 875°C in

the furnace, followed by oil quenching and tempering. Pre-

dicted martensite distribution is shown in Fig. 3b. The gear

tooth is mainly martensite, the core about 20% martensite,

and the remaining structure bainite. About 10% retained

austenite is predicted on the carburized surface of the as-

quenched gear prior to tempering.

Compressive residual stresses are generated in the gear

surface after quenching. Predictedminimumprincipal stress

is shown in Fig. 4a. Both bore and tooth surfaces are under

compression due to the delayed martensitic transformation

in the high carbon case. The root fillet has higher compres-

sive stress compared with that at the tooth flank region,

which is due to the stress concentration of the geometry ef-

fect during quenching.

The directions of minimum principal stresses vary

at different locations of the gear. Minimum principal

residual stress at the root fillet is in the tangential direction

after quench hardening. Tangential stress also directly re-

lates to fatigue crack initiation and propagation at the root

fillet. A local cylindrical coordinate system is defined to plot

the tangential stresses in the gear root fillet (Fig. 4b). The

center of the cylindrical coordinate systemmatches the cen-

ter of the gear fillet. The highest residual compression at the

fillet is about 700 MPa, close to the center of the root. Using

the local coordinate system, the stress contour close to the

root fillet represents tangential stress, but stresses in this di-

rection aremeaningless for locations far away from the fillet.

MODELING GEAR STRESSES UNDER LOAD

Using the rotational bending setup shown in Fig. 2,

stress evolution under a constant torque load of 3287 Nm

is modeled using a linear elastic model. The highest tensile

stress occurs at the root fillet during gear rotation. Without

considering residual stresses from the heat treatment, snap-

shots with the highest stress magnitude are shown in Figs.

5a and 5b for both gear pair sizes. Reducing the gear size by

25% in the

x

-

y

plane generates 1075 MPa tensile stress at the

root fillet compared with 600 MPa for the original size gear.

Compressive residual stresses introduced by heat

treating significantly benefits the gear’s high-cycle bending

fatigue strength. In this study, residual stresses from the

hardening process shown in Fig. 4 are imported to the tor-

sion load model. Under the same constant torque load of

3287 Nm, predicted maximum principal stress contour is

shown in Fig. 6. To more clearly show the effect of residual

stresses, the values are imported to the left (driven) gear

only. The highest stress generated at the surface of the root

fillet is slightly below 600 MPa, significantly lower than the

value of 1075 MPa without considering residual stresses.

From the contour plots shown in Fig. 6b, the highest stress

is under the surface. The location under the surface could

have a lower probability of crack initiation than that at the

surface, even with higher tensile stress.

(a) (b)

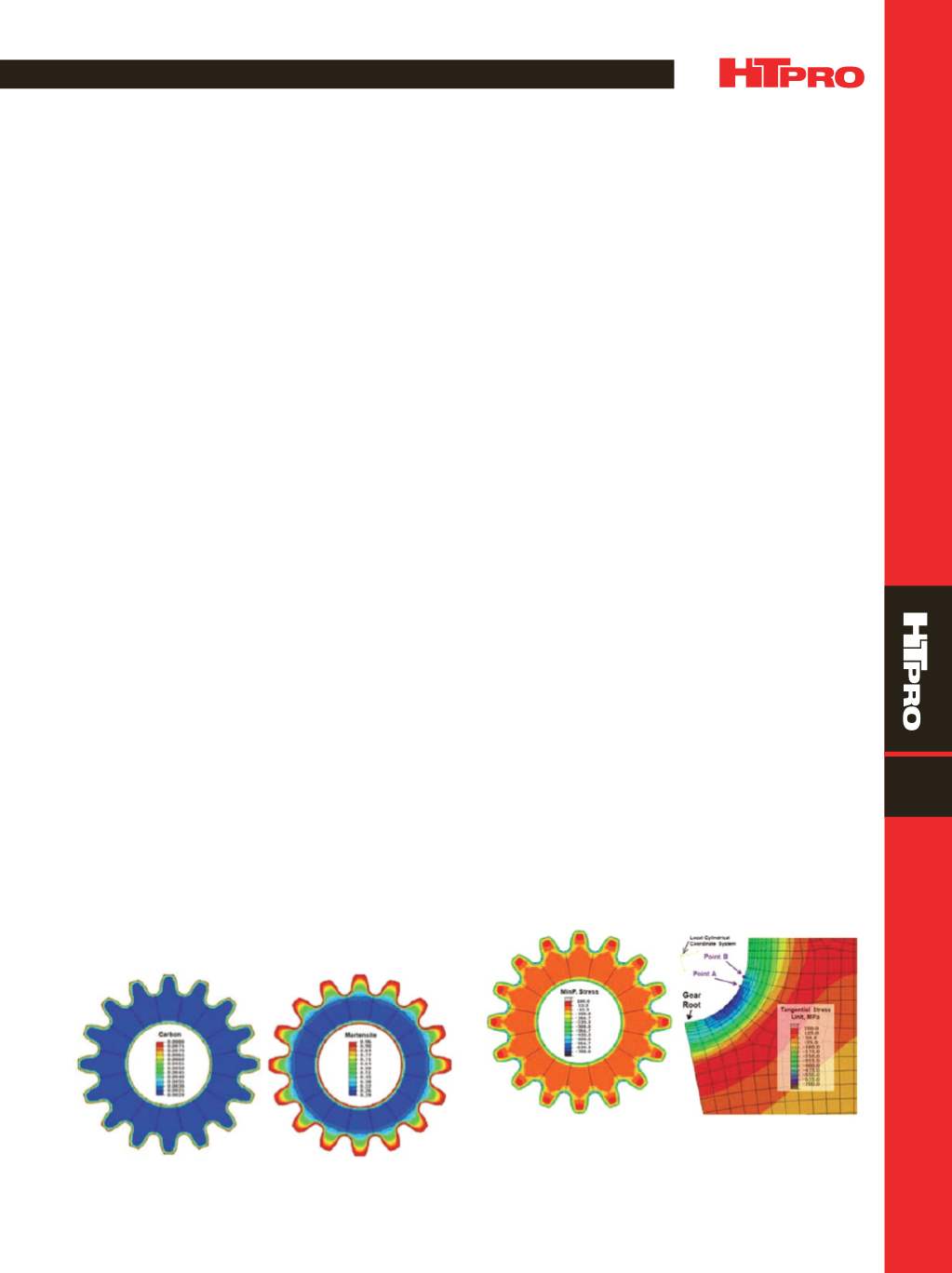

Fig. 3 —

Predicted distributions of (a) carbon, and (b) martensite

after hardening.

(a) (b)

Fig. 4 —

Distribution of residual stresses after carburization and

oil quench: (a) minimumprincipal stress (MPa), and (b) tangential

stress along the root fillet of gear using defined local cylindrical

coordinate system.