A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

5 0

10

FEATURE

REDUCING GEAR SIZE FOR COMPACT TRANSMISSION

DESIGN USING COMPUTER MODELING

Modeling shows that achieving required gear performance in a reduced gear size is possible

by changing the steel grade and heat treatment parameters during the design stage.

Zhichao (Charlie) Li,* B. Lynn Ferguson,* FASM, and Andrew Freborg,*

DANTE Solutions Inc., Cleveland

G

ears are themost important components in transmis-

sion and actuator designs. In many cases, transmis-

sion or actuator design must be reduced to achieve

weight or dimensional advantages without decreasing pow-

er density. One solution is to reduce gear size while keeping

the same output torque capacity. In general, gears used in

heavy load conditions are made of steel, and gear tooth re-

sidual surface stresses are critical to fatigue performance.

Compressive residual stresses in the critical region of a gear

improve its fatigue performance. However, many steel gears

are not processed to obtain residual surface compression, or

the benefit of residual compression is not considered in the

gear and transmission design.

Steel gears are heat treated to increase hardness and

strength for improved performance. Heat treatment intro-

duces compressive residual stresses in the gear surface,

which increases high-cycle fatigue performance

[1–2]

. Carbur-

ization and quench hardening generates compressive re-

sidual stresses in the gear surface due to delayed martens-

ite transformation with volume expansion. These stresses

reduce the magnitude of actual stresses generated in the

critical location of gears under service load. Computer mod-

eling is used to both troubleshoot and design heat treatment

processes for steel parts

[3–9]

. In this article, virtual computer

models using DANTE software are applied to help achieve

gear size reduction by including steel grade hardenability

and heat treatment in the design process.

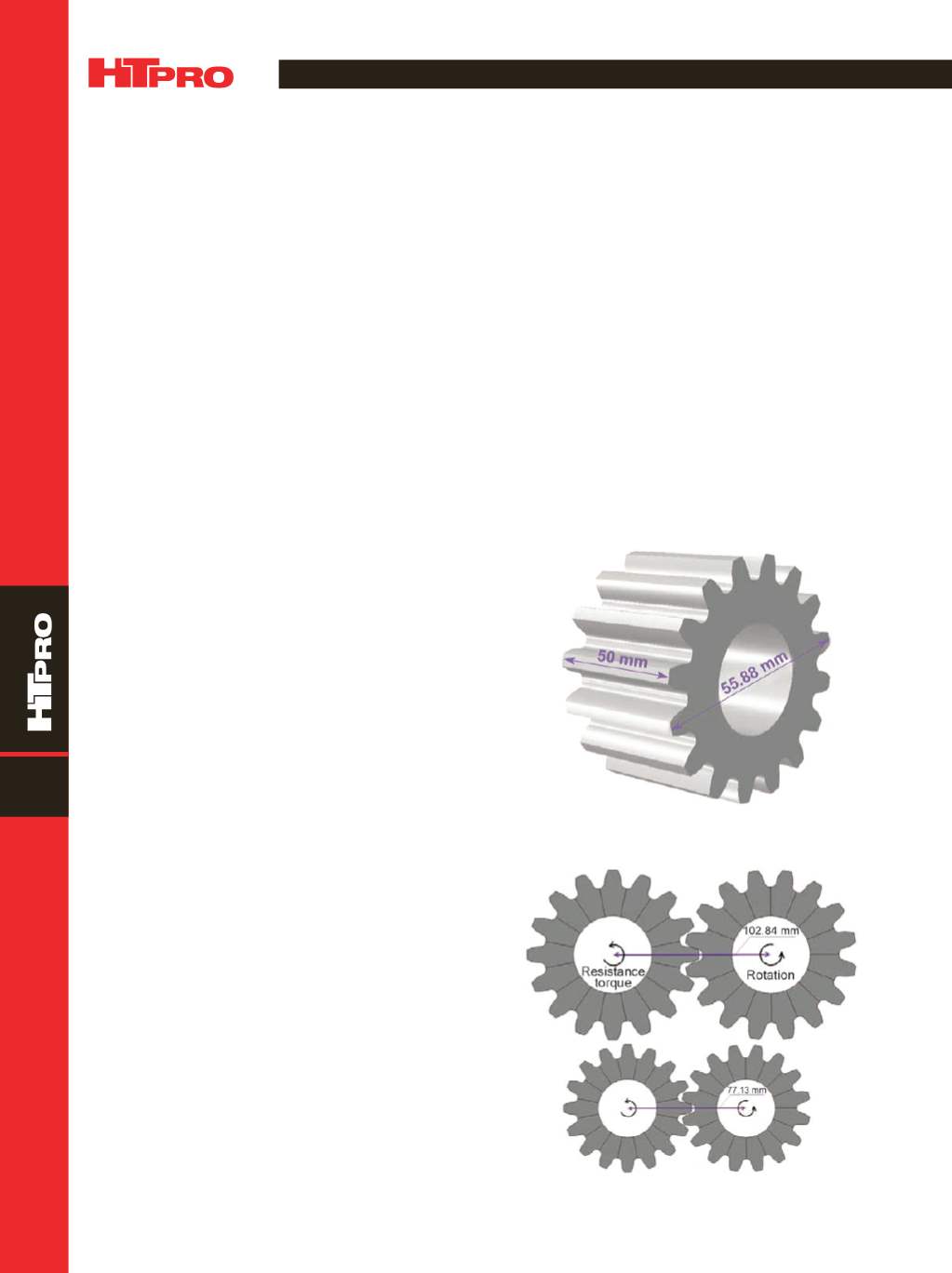

GEAR GEOMETRY

A CAD model of an AISI 4340 alloy steel spur gear with

16 straight teeth selected for this study is shown in Fig. 1.

Gear dimensions are 56 mm OD, 25 mm ID, 44 mm root di-

ameter, and 50 mm thick. Quench hardening in oil is used to

meet specified hardness and strength requirements.

The main concern for this gear is a failure at the gear

root fillet during a high cycle bending fatigue test. Previous

studies show that tangential stress at the root fillet under fa-

tigue load is the main driver of fatigue crack initiation and

propagation. Only one gear mid-plane cross section in the

axial direction is used in this study.

High cycle bending fatigue performance is used as

the main criterion to evaluate gear strength. To simplify the

study, it is assumed that the driver and driven gears are the

same size, and input and output torque (resistance) are the

same. Figure 2a shows the setup of the gear pair under bend-

ing due to rotational torque load for the original gear size de-

sign, with a centerline distance of 103mm. The driven gear is

on the left, with a 3287 N·m resistance torque load applied in

the direction as shown. A rotational displacement is applied

to the gear on the right. Input torque is also 3287 N·m.

DANTE was used to model the oil quench process for

the original 4340 steel gear and the magnitude of predicted

*Member of ASM International and ASM Heat Treating Society

Fig. 1 —

CADmodel and dimensions of original gear.

Fig. 2 —

Dynamic rotational bending model: (a) original gear size,

and (b) scaled reduced gear size.

(a)

(b)