A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 5

5 8

18

FEATURE

the fillet area. The required energy surplus can be achieved

by narrowing the current carrying face of the appropriate

section of the single-shot inductor. For example, if the cur-

rent carrying portion of the inductor heating face is reduced

by 50%, there is a corresponding increase in current densi-

ty, as well as the eddy current density induced within the

respective shaft region. According to the Joule effect, dou-

bling the induced eddy current density increases induced

power density by a factor of four. Also, attaching a magnetic

flux concentrator to certain areas of the hardening inductor

(Fig. 4) further enhances localized heat intensity.

The effects of intensifying heat generation in selected

areas of the shaft (i.e., excessive current densities in induc-

tor sections combined with intense heat radiation from the

workpiece surface) can cause localized copper overheating.

This promotes water vaporization and the formation of a

steam vapor barrier, which essentially functions as a ther-

mal insulator inside the water-cooling pocket. Thus, copper

cooling is severely restricted evenwhen it appears that there

is sufficient water-cooling flow and regardless of the use of

high-performance pumps. To help prevent overheating,

water-cooling pockets are placed as close as possible to the

current carrying face of an inductor. However, coil overheat-

ing can still occur and cause accelerated deterioration of the

copper surface, which speeds up the onset of inductor cop-

per cracking (due to stress fatigue and stress corrosion, for

example) and eventual premature coil failure. As a result, coil

life is often shortened to 22,000-24,000 heat cycles (industry

average). Therefore, the number of instances where coil cur-

rent density is increased should be kept to a minimum.

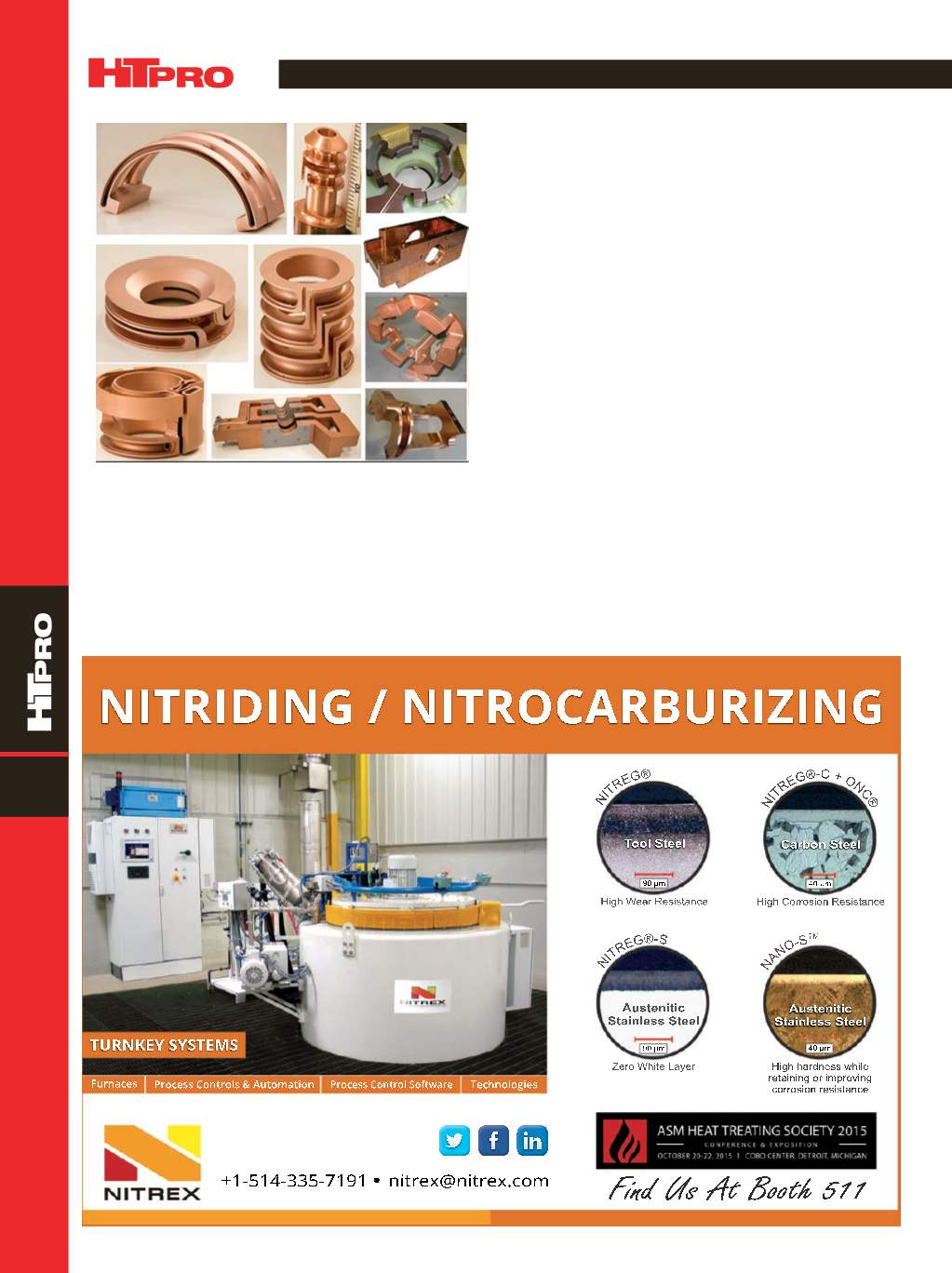

Fig. 2 —

Variety of finished and semifinished CNC-machined

hardening induction coils.