A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 5

6 3

23

TECHNICAL SPOTLIGHT

providing a surface with five times the hardness of the base

material. Figure 2 shows examples of treated industrial parts.

The microstructures and hardness of an ultrafast borided pis-

ton ring and pin are shown in Fig. 3. The superior properties

produced by the process offer substantially longer product

life, which indirectly reduces costs and energy consumption

byminimizing repair and/or replacement of failed parts.

The electrochemical nature of the boriding process re-

quires expertise in electrical engineering, electrochemistry,

materials science, ceramics, furnace design, and various

types of electrical power sources. Researchers from ANL in-

clude Ali Erdemir (ANL project lead), surface engineering ex-

pert Osman Eryilmaz, Gregory Krumdick (safety and quality

control), and postdoctoral scientist Vivekanand Sista (borid-

ing furnace instrumentation and operation). Experts from

the Istanbul Technical University include Servet Timur, Gul-

dem Kartal, and Ozgenur Kahvecioglu Feridun. Mario Ciam-

pini fromBodycote served as liaison inmany aspects related

to the industrial-scale boriding system specification, bench-

marking, field evaluation, and technology transfer issues.

For more information:

Ali Erdimir, FASM, is an Argonne Dis-

tinguished Fellow and senior scientist, Energy Systems Div.

Argonne National Laboratory, 630.252.6571,

erdemir@anl. gov,

www.anl.gov.

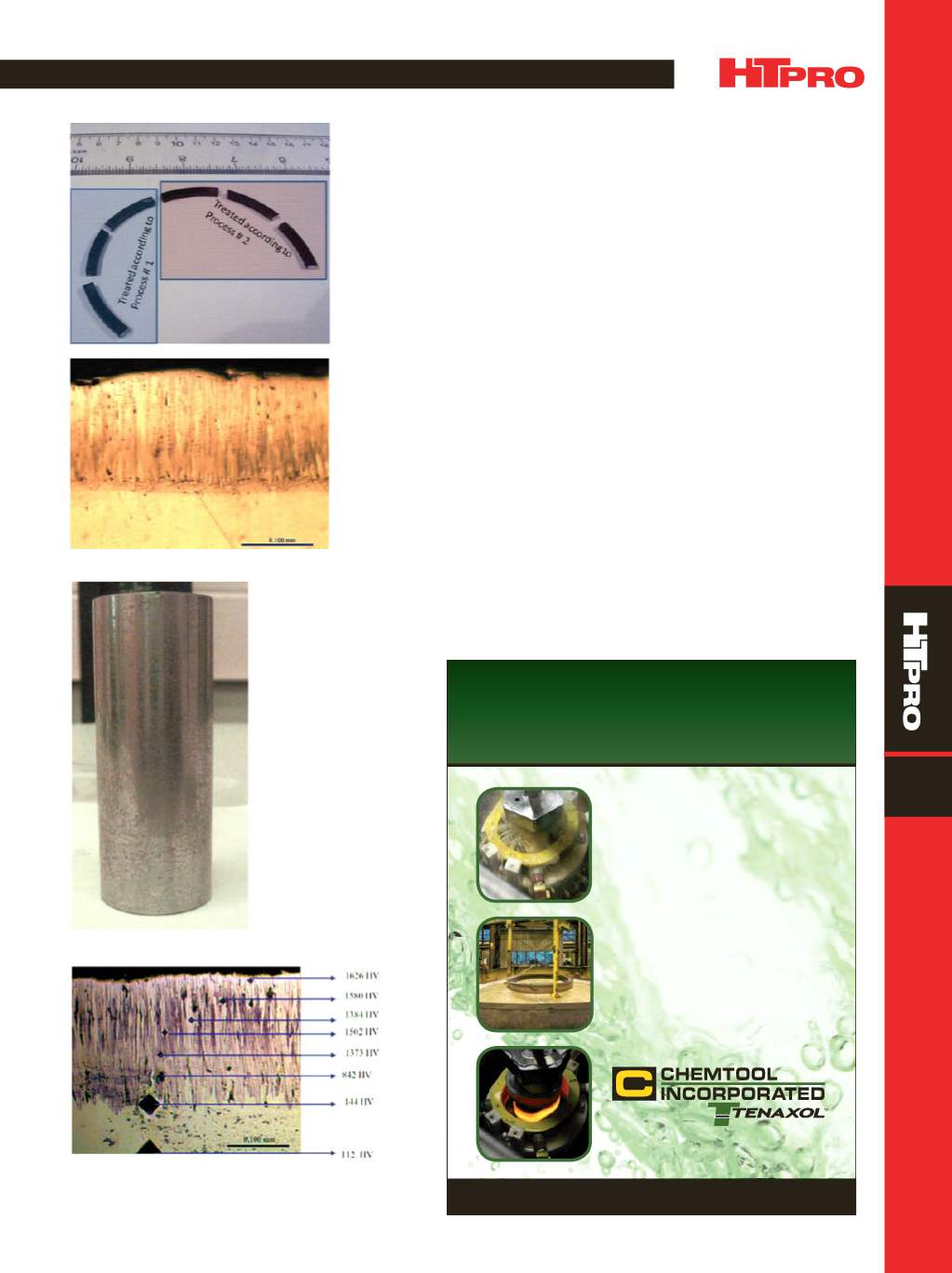

Fig. 3 —

Treated engine parts and cross-sectional microstruc-

tures: (a) piston ring, (b) piston pin.

(a)

(b)

Tenaxol ™ was purchased by Chemtool Incorporated in 2013. Same great product, new owner. Chemtool Incorporated brings a wide assortment of grease, lubricants, metal working fluids, cleaners, corrosion inhibitors, quenchants, diecast and hydraulic oils. Tenaxol ™ is a leading brand in polymer quenchants for the heat treat industry. Call 815-957-4140 PIONEERS IN POLYMER QUENCHANTS www.tenaxol.com