Start Counting Your Savings

RULE #1.

Choose the least expensive

heat rejection technology

RULE #2.

Use hybrid systems to save energy

RULE #3.

Get some expert advice. Make it pay to go green!

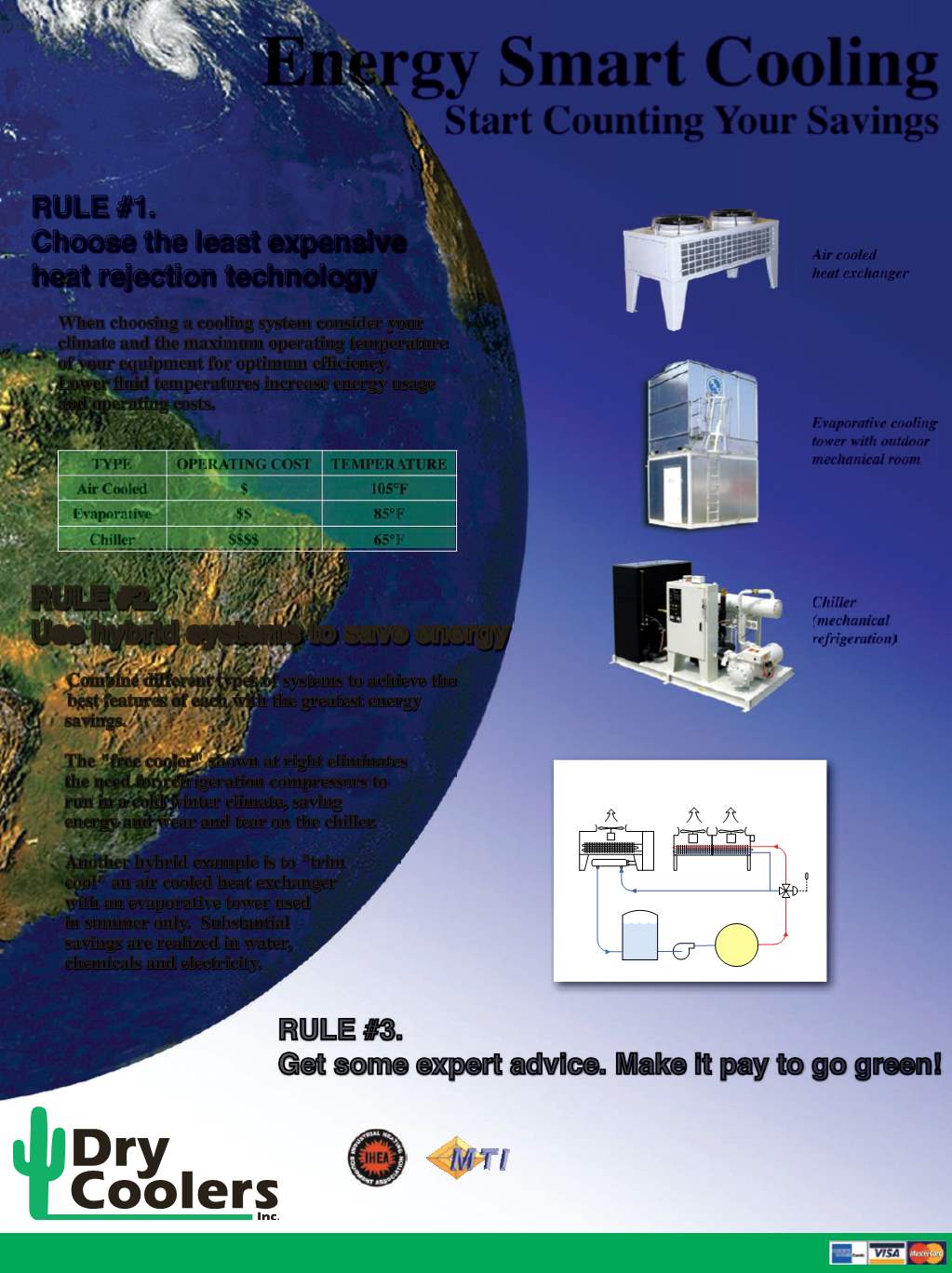

Air cooled

heat exchanger

Chiller

(mechanical

refrigeration)

Evaporative cooling

tower with outdoor

mechanical room

����

�

����

����������

�������

�

���

�

����������

���

�

�

���

�������������

�

����������������

���������

����

�����������

�������������

Combine different types of systems to achieve the

best features of each with the greatest energy

savings.

The "free cooler" shown at right eliminates

the need for refrigeration compressors to

run in a cold winter climate, saving

energy and wear and tear on the chiller.

Another hybrid example is to "trim

cool" an air cooled heat exchanger

with an evaporative tower used

in summer only. Substantial

savings are realized in water,

chemicals and electricity.

TYPE OPERATING COST TEMPERATURE

Air Cooled

$

105°F

Evaporative

$$

85°F

Chiller

$$$$

65°F

When choosing a cooling system consider your

climate and the maximum operating temperature

of your equipment for optimum efficiency.

Lower fluid temperatures increase energy usage

and operating costs.

3

0 years serving the Heat Treating Industry.

call

800-525-8173

Fax: 248-969-3401

575 S. Glaspie Street

• Oxford, MI 48371

www.drycoolers.com

ENERGY-SMART COOLING SOLUTIONS FOR ALL TYPES OF PROCESS EQUIPMENT

ISO 9001:2000

Find us at Booth 415

Start Counting Your Savings

RULE #1.

Choose the least expensive

heat rejection technology

RULE #2.

Use hybrid systems to save energy

RULE #3.

Get some expert advice. Make it pay to go green!

Air cooled

heat exchanger

Chiller

(mechanical

refrigeration)

Evaporative cooling

tower with outdoor

mechanical room

����

�

����

����������

�������

�

���

�

����������

���

�

�

���

�������������

�

����������������

���������

����

�����������

�������������

Combine different types of systems to achieve the

best features of each with the greatest energy

savings.

The "free cooler" shown at right eliminates

the need for refrigeration compressors to

run in a cold winter climate, saving

energy and wear and tear on the chiller.

Another hybrid example is to "trim

cool" an air cooled heat exchanger

with an evaporative tower used

in summer only. Substantial

savings are realized in water,

chemicals and electricity.

TYPE OPERATING COST TEMPERATURE

Air Cooled

$

105°F

Evaporative

$$

85°F

Chiller

$$$$

65°F

When choosing a cooling system consider your

climate and the maximum operating temperature

of your equipment for optimum efficiency.

Lower fluid temperatures increase energy usage

and operating costs.

3

0 years serving the Heat Treating Industry.

call

800-525-8173

Fax: 248-969-3401

575 S. Glaspie Street

• Oxford, MI 48371

www.drycoolers.com

ENERGY-SMART COOLING SOLUTIONS FOR ALL TYPES OF PROCESS EQUIPMENT

ISO 9001:2000

Find us at Booth 415