A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 5

2 4

•

Testing procedures or methods

•

Calculations or results to be

determined

Even though standards provide

these details, some aspects may still

be left to interpretation, which can

often lead to variations in testing per-

formance. Additionally, if a lab is test-

ing products to a variety of global or

local standards, it can be challenging

to fully understand and capture sub-

tle differences in terminology and

methodologies.

This article attempts to clarify ar-

eas commonly misinterpreted or mis-

understood by users. The content is

intended to be general and summary in

nature so it can be applied regardless of

which test standard is followed.

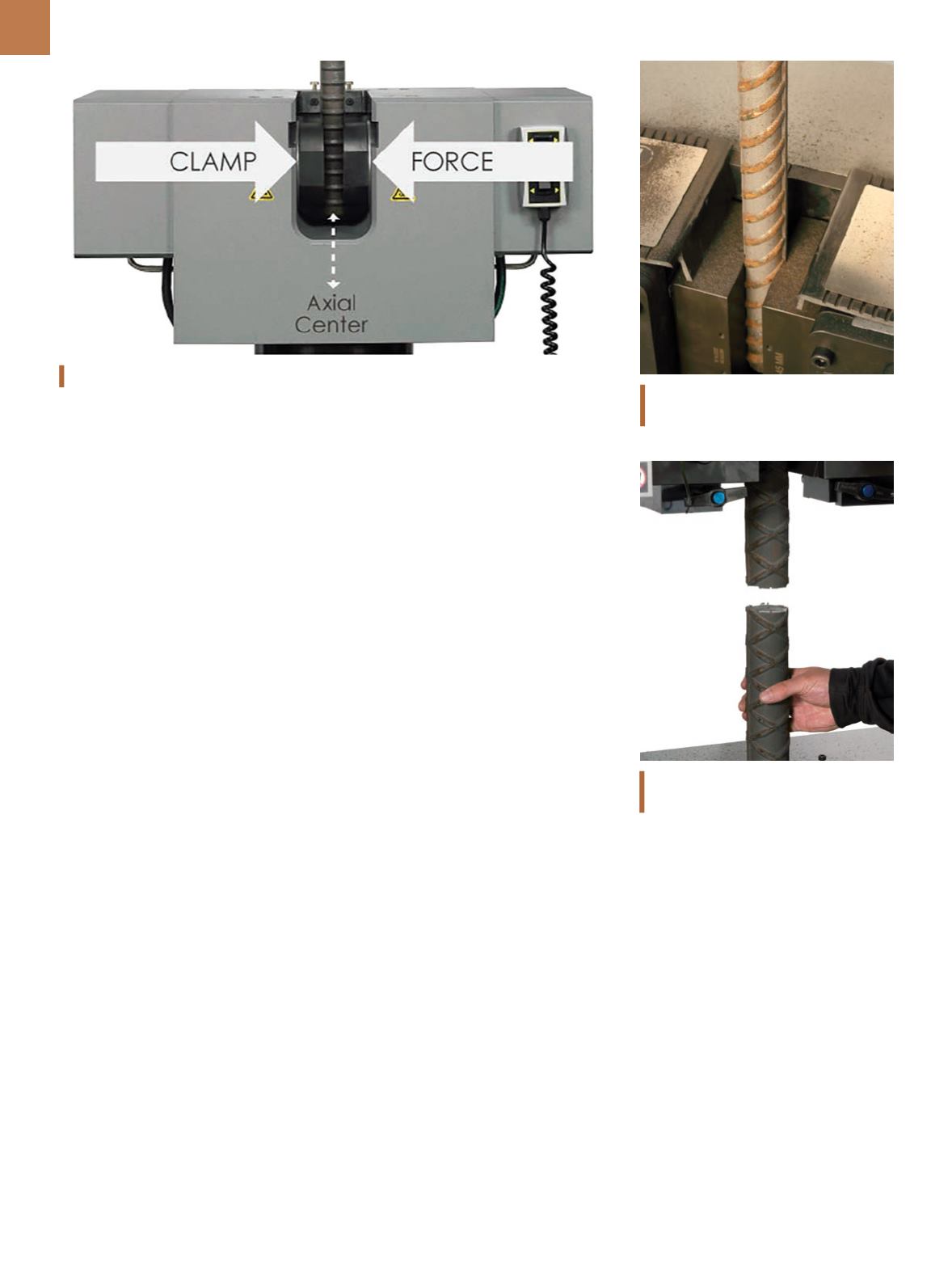

EQUIPMENT CONSIDERATIONS

Accommodating bent specimens:

As standards indicate, rebar specimens

must be straightened prior to tensile

testing. As a result, many test piecesmay

still have a slight bend or nonlinearity

over their length. Therefore, load frame

and grips that are able to accommodate

slightly bent specimens are best.

Grips that mechanically clamp

on center are recommended in order

to maintain axial alignment. Hydraulic

side-acting grips are best for addressing

bent specimens because the mechani-

cal balancing (synchronizing) between

the two sides allows them to always

clamp on center even when side loads

from bent specimens act against the

jaws closing. This helps improve align-

ment and eliminates resetting of grips

between tests. Resetting is typically

associated with hydraulically synchro-

nized grip designs that cannot clamp on

center when specimen side loads exist.

Failure to reset these types of grips be-

tween tests can allow misalignment be-

tween upper and lower grips.

Specimen deformations and scal-

ing:

Grip jaws (faces) must accommo-

date deformations and scale common

on rebar specimen surfaces. Scalebuild-

up in the teeth of the jaws can lead to

specimen slippage. Tooth patterns that

are too aggressive can cause premature

specimen failures and may also prevent

the specimen halves from being easily

removed after the test. Therefore, tooth

profiles should allow scale to fall away

naturally or be easily brushed away be-

tween tests. They should also alleviate

failures potentially caused by grips. If

the broken specimen halves remain

stuck in the jaw faces, operators must

dislodge them through use of a ham-

mer or other means, which can reduce

efficiency and add to operator fatigue

and frustration.

The grip’s mechanical functions

should also be protected against falling

scale. If scale is allowed to get between

moving parts, critical surfaces can be

galled and lead to poor performance

or grip failure. Regular removal of scale

from testing equipment is important

to help prevent unnecessary wear and

tear.

Violent specimen failures:

Because

rebar specimens release a lot of stored

energy during tensile failure, the test-

ing system must be able to withstand

the shock that results from specimen

recoil. Grips are most impacted and

must be robust enough to absorb the

energy and still hold the broken spec-

imen halves so they do not eject from

the testing frame. Flying specimen piec-

es could become a safety hazard to the

operator and can also damage equip-

ment. For these reasons, hydraulically

actuated grips (wedge or side-acting)

are recommended.

Extensometers:

Extensometers are

not always required when testing rebar.

Instron DuraSync side-acting grips clamping rebar specimen on center.

Abundant scale accumulation on lower

grip after one test.

Number 18 (57 mm) bar separation

(recoil) after failure.