1 9

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 5

A

coustic microscopes pulse ultra-

sound into a sample and use the

return echoes to find and image

cracks, delaminations, and other gap-

type flaws in manufactured parts and

products. New developments in micro-

scope technology, such as those taking

place at Sonoscan Inc., enable mapping

of the point-by-point contour of tilted or

warped interfaces, as well as individual

material layer thicknesses.

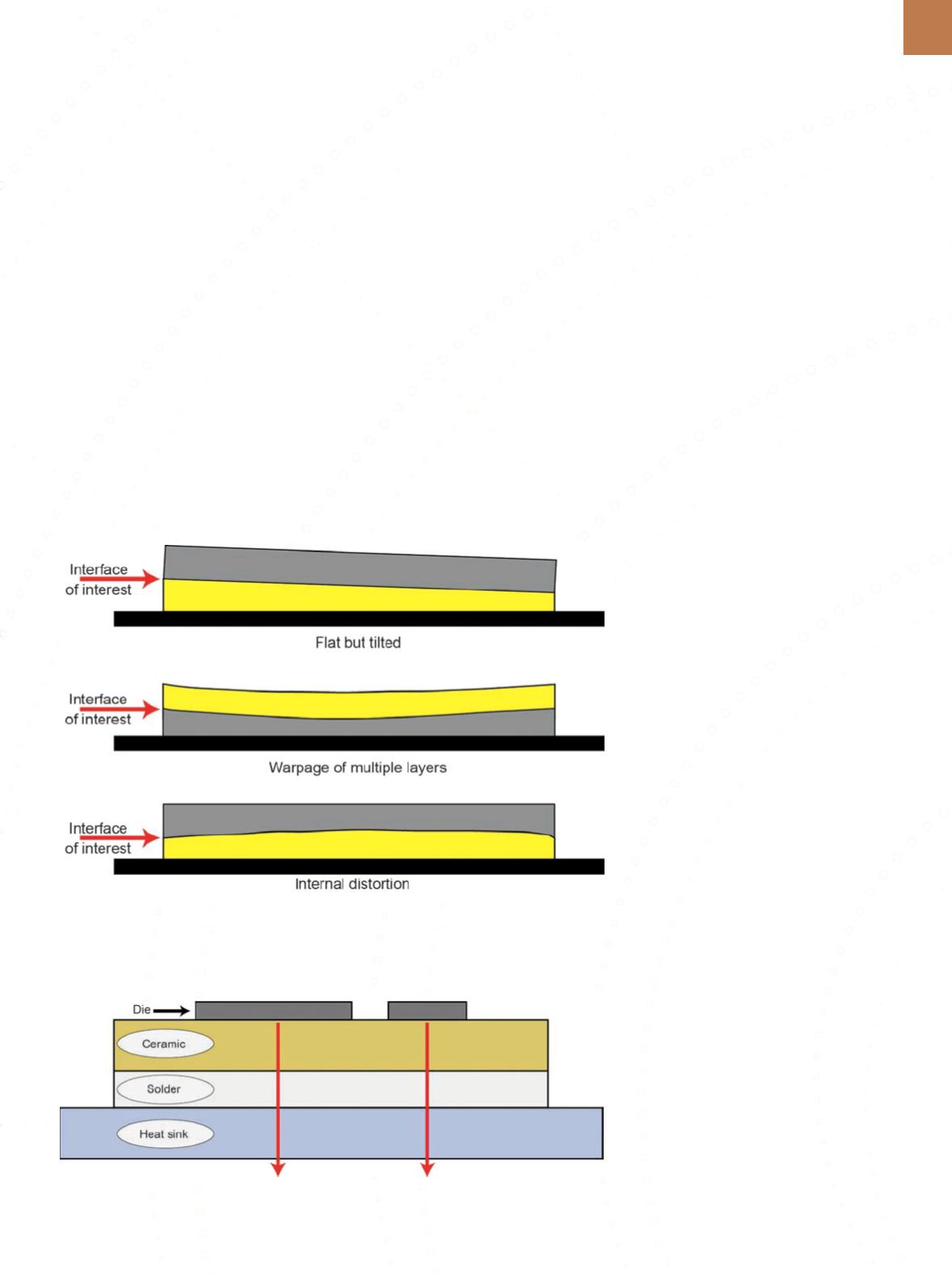

If all layers are flat and parallel to

each other, the acoustic image map of

any internal interface will contain uni-

form color pixels because they are all

the same distance from the scanning

ultrasonic transducer. However, an as-

sembly may contain interfaces that are

tilted or warped, as shown in Fig. 1. In

some instances, both warped

and

tilt-

ed interfaces are present in the same

assembly.

In many applications, design con-

straints require these buried layers to

be flat, horizontal, and of uniform thick-

ness, although acoustic imaging may

show different internal geometry. For

example, power insulated gate bipolar

transistor (IGBT) modules often strug-

gle with buried layers. Fast-switching

IGBT modules are frequently used to

handle heavy loads in critical applica-

tions such as railroad engines, heavy

mining equipment, and electric auto-

mobiles. Due to high current levels, the

silicon die that actually performs the

switching must disperse large amounts

of heat.

IGBTmodules are designed so that

heat flows downward through ceramic

plates called

rafts

to a metal heat sink

that dissipates heat into the surround-

ing air (Fig. 2). If the heat sink, raft, and

die are all horizontal and parallel, and

if there are no voids (air bubbles) or

other gaps in the solder bond, heat will

flow downward (arrows in Fig. 1) at the

designated rate. However, if voids are

present or the raft (and perhaps the die

itself) are tilted, heat flow will not meet

specifications, likely causing the die to

overheat and fail electrically.

Acoustic microscopes can image

internal material interfaces fairly quick-

ly because the transducer that pulses

the ultrasound and receives the echoes

from the internal features moves later-

ally at speeds that can exceed 1 m/s.

In addition, the speed of ultrasound

through production materials such as

metals, ceramics, and polymers is typi-

cally measured in thousands of m/s.

Because most sample thicknesses

are measured in millimeters, the pulse

is launched and echoes are received in a

fewmillionths of a second. Consequent-

ly, the moving transducer can receive

echoes from thousands of locations per

second as it scans. Echoes may come

from a solid-to-solid material interface,

or in the case of gap-type defects, a

solid-to-gas (e.g., air) material inter-

face. Each location contributes one pix-

el to the sample’s acoustic image.

IGBT modules are imaged by scan-

ning the transducer, which is inverted,

across the surface of the metal heat

sink at the bottom of the assembly.

Because the transducer’s ultrasound

needs to be coupled to the surface, con-

tact is maintained by a water plume. At

each location, the return echo’s ampli-

tude provides information about the

two materials at the interface. Solid-to-

solid interfaces tend to have lower am-

plitude echoes. Solid-to-gas interfaces

reflect virtually 100% of the ultrasound

and thus produce much higher ampli-

tude echoes that become bright white

pixels in the acoustic image. While

imaging the depth in a sample where

two solid materials are supposed to be

joined, there should be no white areas

indicating voids, delaminations, or oth-

er gaps.

The elapsed time from pulse

launch to echo return is also measured

and recorded. This indicates that the

image comes from within the vertical

extent of the depth of interest (known

Fig. 1 —

Three major types of internal nonplanarity.

Fig. 2 —

Arrows show desired path of heat dissipation from an IGBT module.