2 1

A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 5

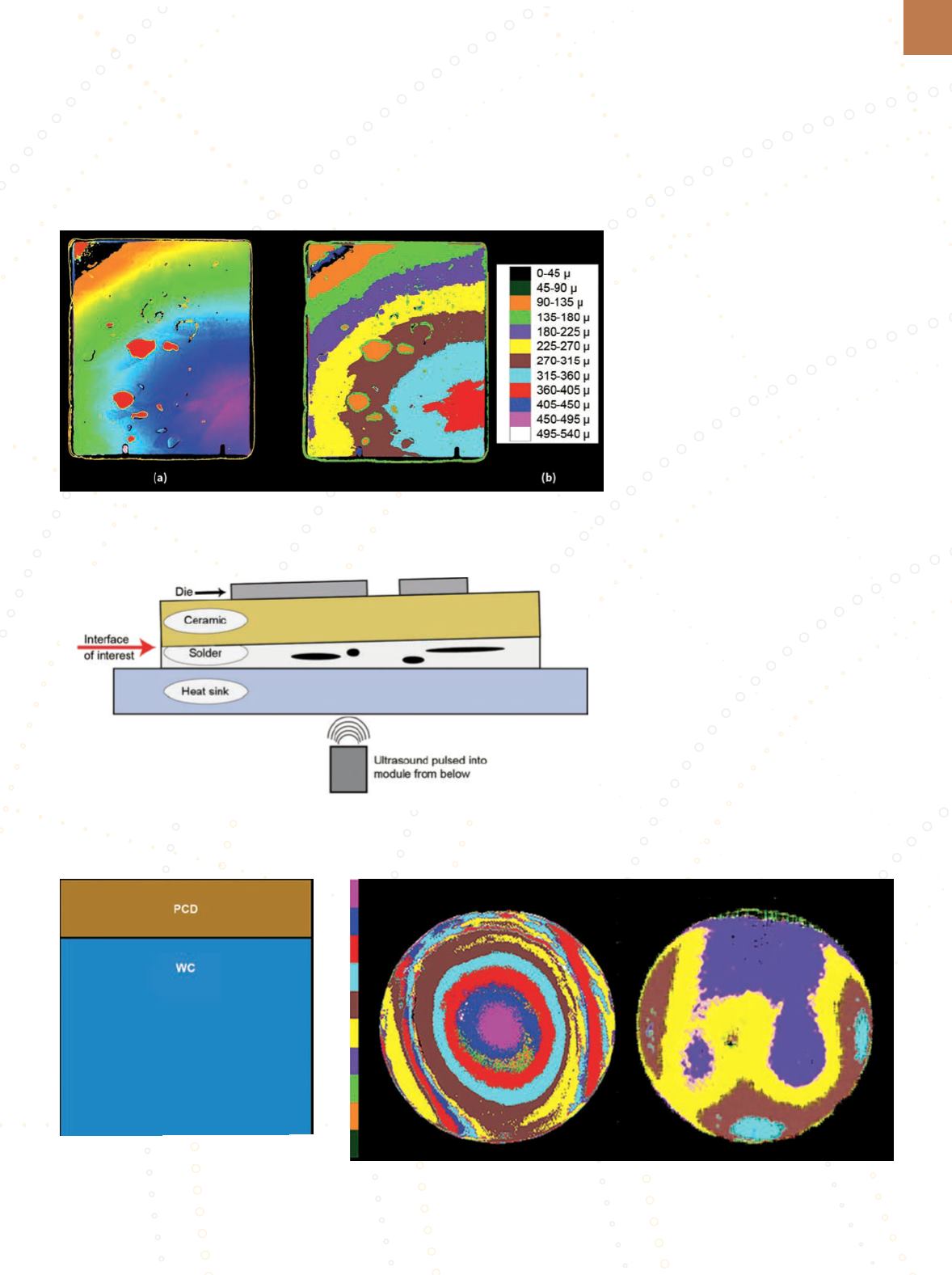

Fig. 3 —

Time difference mode image of solder thickness in IGBT module with a tilted raft (a).

Scale indicates solder thickness (b).

Fig. 4 —

Diagrammatic side view of a module with a tilted raft.

Fig. 5 —

Side view diagram of a portion of

an ideal polycrystalline diamond/tungsten

carbide wafer.

Fig. 6 —

Time difference mode images of two wafers exhibiting extreme variation in PCD thick-

ness (left), andmuch less variation with far more usable area (right).

the brown and pale blue regions on the

two wafers.

The left wafer features many obvi-

ous variations in PCD thickness over

short distances. Over the whole wafer,

PCD thickness ranges from about

0.45 mm to 0.80 mm. The thickest region

is near the center, represented by the

magenta color. The result is that only a

small portion of this wafer is usable.

In contrast, the wafer on the right fea-

tures a total PCD thickness variation of

just 0.20 mm, offering a significantly

larger area to be sliced into tool bits.

In both the IGBT sample and the

diamond sample discussed here, one

face of the buried layer is flat and hor-

izontal—i.e., the top of the PCD wafer,

and the top of the IGBT module’s solder

where it interfaces with the rigid metal

heat sink. If a buried layer were distort-

ed on both of its surfaces, this acoustic

method could image both of the buried

layer’s surfaces in separate images and

map the thickness of the distorted bur-

ied layer.

~AM&P

For more information:

Tom Adams is

a consultant for Sonoscan Inc., 2149 E.

Pratt Blvd., Elk Grove Village, IL 60007,

847.437.6400,

info@sonoscan.com,

www.sonoscan.com.

ideal thickness are desirable because

any cutting tool breakdown requires an

expensive and time-consuming repair.

Imaging wafers acoustically pro-

duces a map showing the local depth of

the interface between the PCD and WC,

i.e., the PCD thickness. Figure 6 shows

the acoustic images of two 55-mm wa-

fers. Each color represents a vertical

extent of 0.05 mm. The ideal thickness

for this application is roughly 0.60 mm,

represented by the boundary between