A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 5

1 7

NANOTECHNOLOGY

BRIEFS

Aleris, Cleveland, offers a new 7017 aluminum alloy in North America for commercial plate and defense

uses. After extensive review and testing, the U.S. Army Research Lab issued MIL-DTL-32505 for use in armor

applications. 7017 offers high strength, good weldability, and corrosion resistance. It is currently used in

Europe and Asia on combat vehicles to achieve superior ballistic protection.

aleris.com.

NEW WAY TO GROW METAL

NANOSTRUCTURES

Michael Tringides, physicist at

the DOE’s Ames Laboratory and pro-

fessor of physics and astronomy at

Iowa State University, saw unusual

atom movement when a few thousand

lead atoms were dropped onto a flat,

smooth lead-on-silicon surface, all

at low temperatures, on an area just

one-twentieth the width of a human

hair. Scientists expected to see “ran-

dom-walk diffusion” with atoms mill-

ing around, appearing to have no idea

where they’re going or that any fellow

atoms are near them. Typically, atoms

eventually run into each other and cre-

ate small structures.

“Instead, we saw atoms very fo-

cused and working together to quick-

ly create tiny lead nanostructures,”

says Tringides. “That kind of

collective

diffusion

is really the exception to the

rule in atom movement. Plus, we were

surprised by how fast well-organized

crystal structures nucleate at such cold

temperatures, where movement is typ-

ically slow.”

This collective, fast diffusion

could represent a new way to grow per-

fect, tiny metal nanostructures. “Un-

derstanding the basic science of how

materials work at these nanoscales

may be key to making nanotransis-

tors, nanoswitches, and nanomagnets

smaller, faster, and more reliably,”

says Tringides.

For more information:

Michael Tringides, 515.294.6439,

mctringi @iastat.edu,

physastro.iastate.edu.GRAPHENE FOR FUTURE

SPINTRONIC DEVICES

Researchers at Chalmers Univer-

sity of Technology, Sweden, discovered

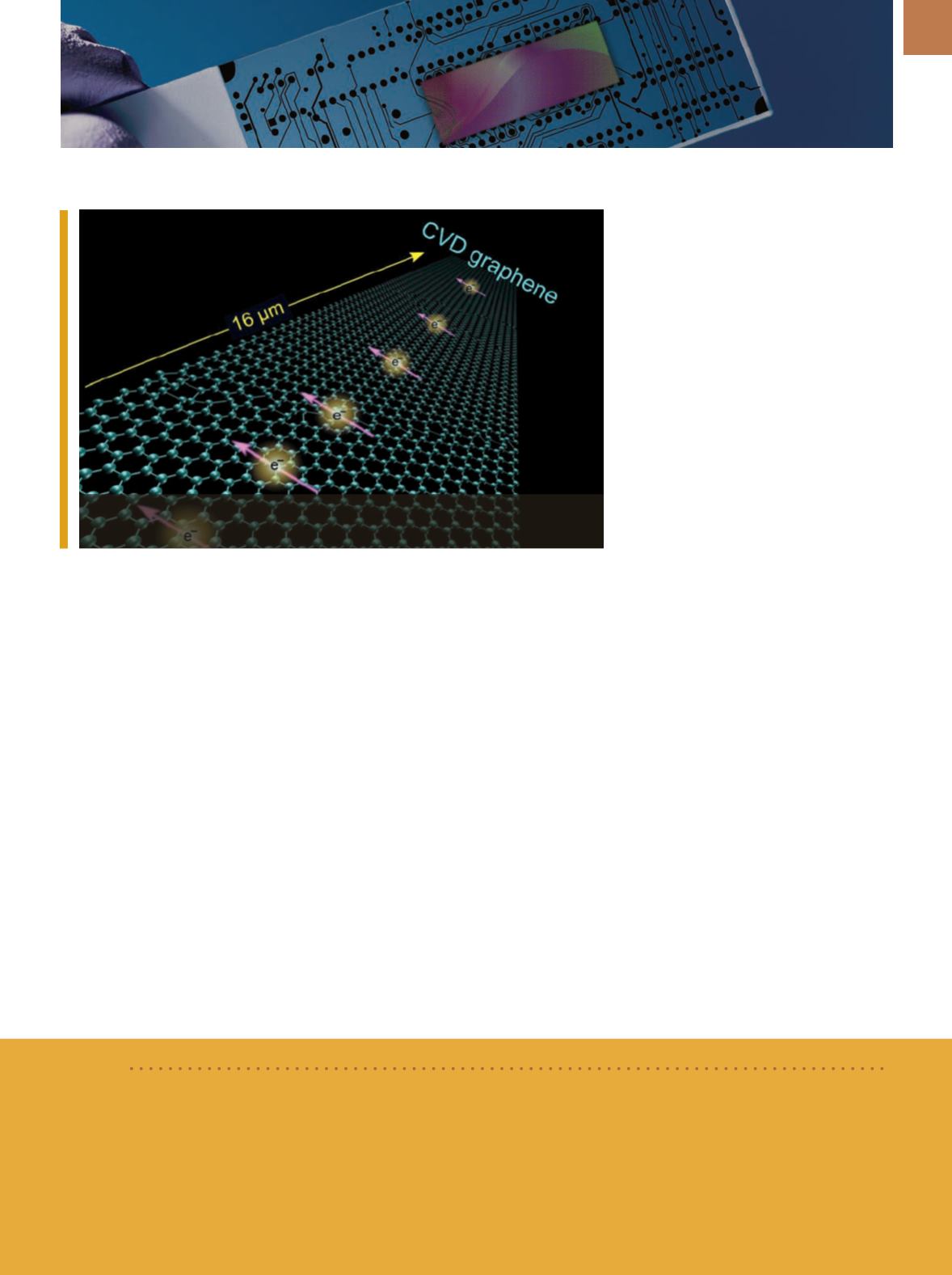

Graphene may enable spintronics to complement traditional electronics. Courtesy of

M. Venkata Kamalakar, et al.

BRIEF

A breakthrough in artific al photosynthesi was achieved through a system that captu es carbon dioxide emissions

before they are vented into he a mosph re and th n, powered by solar ene gy, converts the emissions into valu ble

chemical products, including biodegradable pla ics, p armaceutical drugs, and eve liquid fuels. S ientists with the

DOE’s Lawrence Berkeley Nation l Laboratory,

Calif., nd th

University of California,

B keley,

created a hybrid

system of semiconducting nanowires and bacteria that mimics the natural photosynthetic process. The artificial

system synthesizes the combination of carbon dioxide and water into acetate, the most common building block for

biosynthesis.

lbl.gov,

berkeley.edu.

that large area graphene can preserve

electron spin over an extended peri-

od, and communicate it over greater

distances than previously thought.

This could open the door to spin-

tronics development, with an aim to

build faster and more energy-efficient

memory and processors in computers.

Spintronics is based on the quantum

state of the electrons and the technol-

ogy is already used in advanced hard

drives for data storage and magnetic

random accesses memory. Graphene

is a promising candidate for extend-

ing spintronics use in the electronics

industry. The thin carbon film is not

only an excellent electrical conductor,

but also theoretically has the rare abil-

ity to maintain the electrons with the

spin intact.

Researchers

conducted

their

experiments using CVD graphene,

produced through chemical vapor

deposition (CVD). This method gives

the graphene a lot of wrinkles, rough-

ness, and other defects. But it also

has advantages—there are good pros-

pects for the production of large area

graphene on an industrial scale. CVD

graphene can also be easily removed

from the copper foil on which it grows

and is lifted onto a silicon wafer, which

is the semiconductor industry’s stan-

dard material. Although the quality

of the material is far from perfect,

the group shows parameters of spin

that are up to six times higher than

those previously reported for CVD

graphene on a similar substrate.

www.chalmers.se/en.