A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 5

1 2

PROCESS TECHNOLOGY

BRIEF

Messe Düsseldorf,

Germany, an international trade show organizer for the met-

allurgy industry, launched a new sector portal called

Metsearch,

which offers a

comprehensive product and company database for various metalworking dis-

ciplines. The portal features sector and company news along with background

information on the industrial segments of national and international trade fairs,

as well as monthly highlights about different topics of interest to metallurgists.

metsearch.net.“Conductors made of liquid metal can

stretch and deform without breaking.”

One potential manufacturing ap-

proach uses inkjet printing to create

devices made of liquid alloys. Printable

ink is made by dispersing the liquid

metal in a nonmetallic solvent using

ultrasound, which breaks up the bulk

liquid metal into nanoparticles. This

nanoparticle-filled ink is compatible

with inkjet printing.

“Liquid metal in its native form is

not inkjet-able,” says Kramer. “So what

we do is create liquid metal nanoparti-

cles small enough to pass through an

inkjet nozzle. Sonicating liquid metal in

a carrier solvent, such as ethanol, both

creates nanoparticles and disperses

them in the solvent. Then we can print

the ink onto any substrate. Ethanol

evaporates away so just liquid metal

nanoparticles are left on a surface.”

After printing, the nanoparticles

must be rejoined by applying light

pressure, making it conductive. This

step is necessary because liquid-metal

nanoparticles are initially coated with

oxidized gallium, which prevents elec-

trical conductivity. It is possible to select

which portions to activate depending

on particular designs, suggesting that

a blank film might be manufactured for

a multitude of potential applications.

The process could make it possible to

rapidly mass-produce large quantities

of the film. Future research will explore

how the interaction between the ink and

the surface being printed on might be

conducive to making specific types of

devices.

For more information: Rebecca

Kramer, 765.494.2219,

rebeccakramer@ purdue.edu,

www.purdue.edu.

NEW PATENT COVERS

ALUMINUM ACID ETCHING

Houghton International Inc. and

Houghton Technical Corp., Valley Forge,

Pa., announce that the Canadian Patent

Office issued Patent No. 2,618,915,

Meth-

ods and Compositions for Acid Treatment

of a Metal Surface.

This patent is directed

towards Houghton’s technology for alu-

minum acid etching, which is formulat-

ed to provide a uniform fine matte satin

finish on aluminumand aluminumalloys

prior to anodizing and/or coloring. Unlike

alkaline etching, this technology produc-

es a superior matte finish while signifi-

cantly reducing aluminum removal and

sludge waste. It is performed at lower

temperatures and requires less process-

ing time compared to conventional caus-

tic etch systems.

houghtonintl.com.

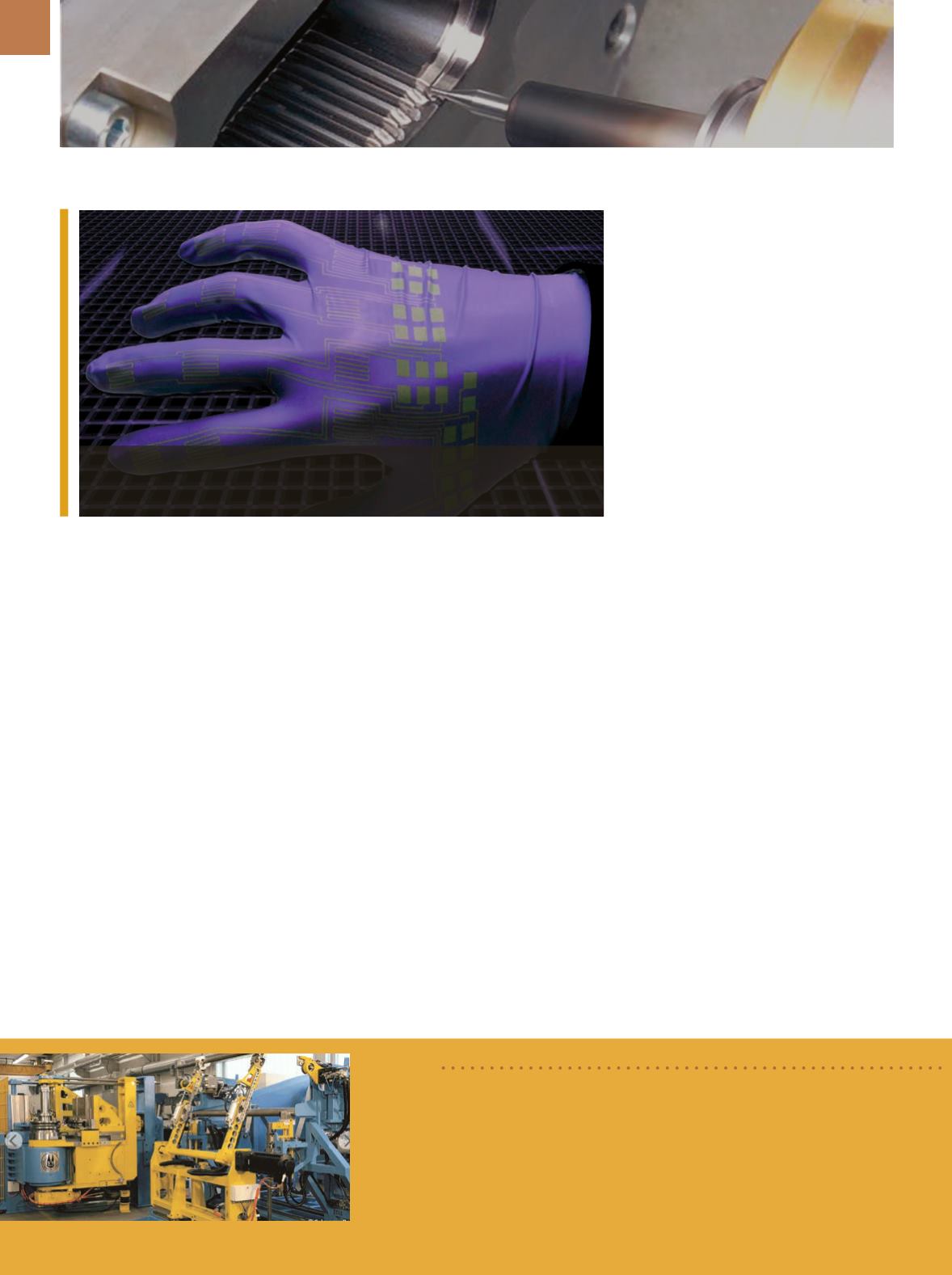

Artistic rendering depicts electronic devices created using a new inkjet-printing

technology to produce circuits made of liquid-metal alloys for soft robots and

flexible electronics. Courtesy of Alex Bottiglio/Purdue.

INKJET PRINTING WITH

LIQUID METAL

New research shows how inkjet-

printing technology can be used to

mass-produce electronic circuits made

of liquid-metal alloys for soft robots

and flexible electronics. Elastic technol-

ogies could enable a new class of pli-

able robots and stretchable garments

that people might wear to interact with

computers or for therapeutic purpos-

es. However, new manufacturing tech-

niques must be developed before soft

machines become commercially fea-

sible, says Rebecca Kramer, assistant

professor of mechanical engineering at

Purdue University, West Lafayette, Ind.

“We want to create stretchable

electronics that might be compatible

with soft machines, such as robots

that need to squeeze through small

spaces, or wearable technologies that

don’t restrict motion,” explains Kramer.