A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 5

1 0

TESTING | CHARACTERIZATION

BRIEFS

Aleris, Cleveland, offers a new 7017 aluminum alloy in North America for commercial

plate and defense uses. After extensive review and testing, the U.S. Army Research

Lab issued MIL-DTL-32505 for use in armor applications. 7017 offers high strength,

good weldability, and corrosion resistance. It is currently used in Europe and Asia on

combat vehicles to achieve superior ballistic protection.

aleris.com.

TRIPLE THREAT INSTRUMENT

PROBES CHEMISTRY,

TOPOGRAPHY, MECHANICS

Atomic force microscopes (AFMs)

scan surfaces to reveal details at a res-

olution 1000 times greater than that of

optical microscopes, which is ideal for

analyzing physical features but does not

work for chemical analysis—researchers

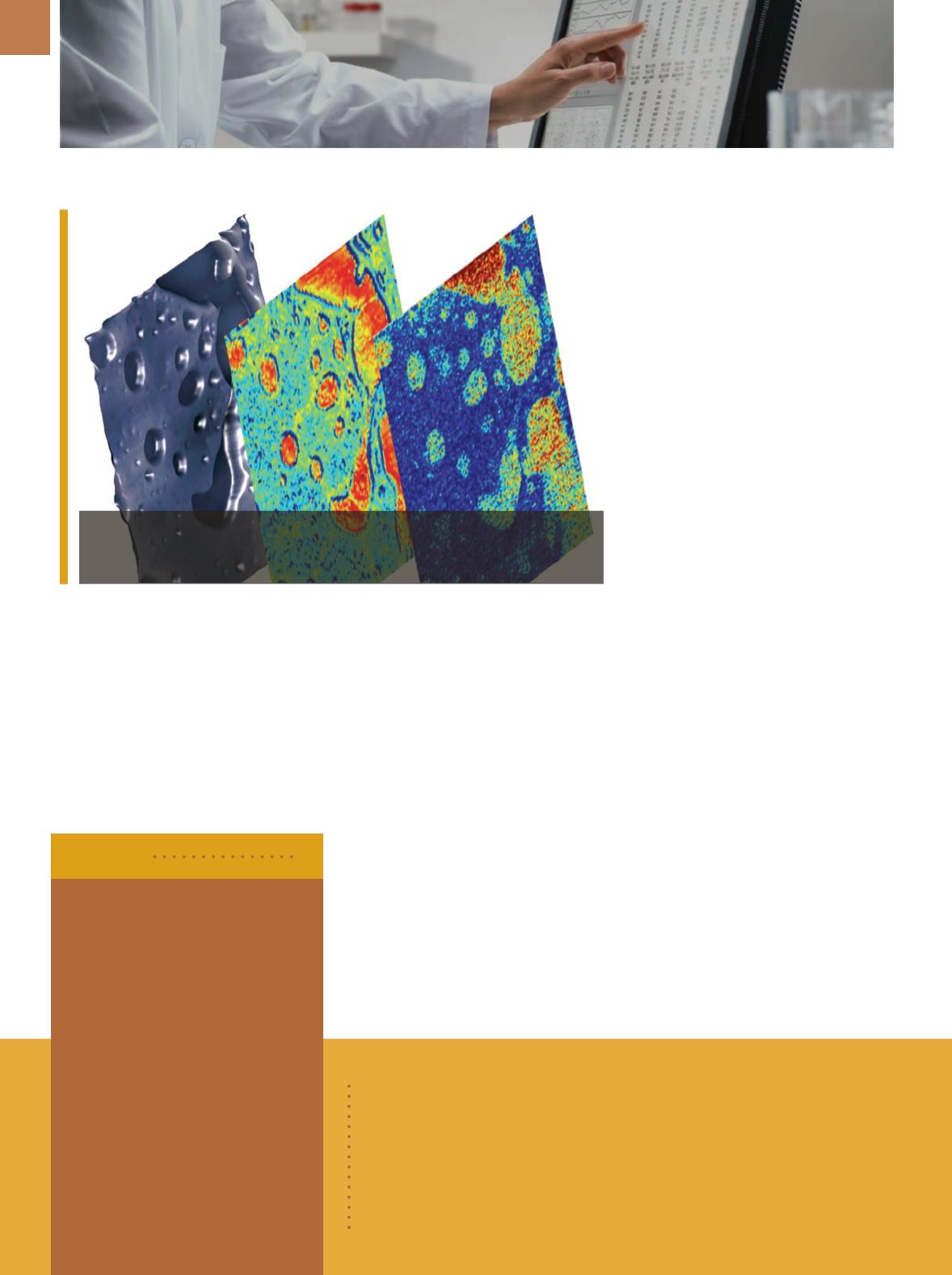

For a 500-nm-deep polymeric thin filmmade of polystyrene (lighter) and poly-2-

vinylpyridine (darker), onemultimodal instrument imaged, from left, surface topogra-

phy, elasticity of the bulkmaterial, and buried chemical behavior. Courtesy of ORNL.

This new technique for functional

imaging allows probing of regions on

the order of nanometers to character-

ize a sample’s surface hills and valleys,

elasticity throughout deeper layers,

and chemical composition. Previously,

AFM tips could penetrate only 20 nm to

explore a substance’s ability to expand

and contract. Adding a thermal desorp-

tion probe to the mix allows scientists

to probe deeper, as the technique cooks

matter off the surface and removes it as

deep as 140 nm.

ornl.gov.

ENGINEERS PREPARE TO

ANALYZE ORION HEAT SHIELD

Engineers from three NASA field

centers are working together at NASA’s

Marshall Space Flight Center in Hunts-

ville, Ala., to remove and analyze 180

small squares of an ablative material

called Avcoat—the outer coating of the

heat shield that protected the Orion

crew module during its 2014 flight test.

NASA is developing the spacecraft to

carry future astronauts on new missions

to an asteroid and to Mars. Charred

during the test flight known as Explora-

tion Flight Test 1, or EFT-1, the 16.5-ft-

diameter heat shield arrived at Marshall

onMarch9. Itwas installed in the center’s

seven-axis milling machine, which uses

computer-aided tools to manufacture

parts and cut large metal or composite

materials or structures. Built for NASA

by Lockheed Martin of Huntsville, the

machine is the largest of its kind in the

world except its twin at NASA’s Michoud

Assembly Facility in New Orleans.

must use mass spectrometers. A team

from the DOE’s Oak Ridge National

Laboratory, Tenn., has combined these

capabilities into one instrument that

can probe a sample in 3D and overlay

information about surface topogra-

phy, atomic-scale mechanical behavior

near the surface, and chemistry at and

beneath the surface. This multimodal

imaging allows scientists to explore

thin films of phase-separated polymers

important for energy conversion and

storage.

“Combining the two capabilities

marries the best of both worlds,” says

project leader Olga Ovchinnikova. “For

the same location, you get not only

precise location and physical charac-

terization, but also precise chemical

information.”

A novel x-ray scattering concept

by researchers at

Lawrence

Berkeley National Laboratory’s

Advanced Light Source

(ALS),

Calif., is receiving $2.4 million in

support from the

Gordon and

Betty Moore Foundation.

Funding

will enable development of a new

spectrometer to study materials

via x-ray scattering. The grant is

part of the Foundation’s

Emergent

Phenomena in Quantum Systems

initiative, which “strives to deepen

our understanding of the com-

plex collective behavior electrons

exhibit in materials and engineered

structures.”

lbl.gov.

BRIEFS

Grafoid Inc.,

Canada, acquired analytical services provider

MuAnalysis

Inc.,

Ottawa, Ontario. MuAnalysis provides analysis to the electronics,

photonics, life sciences, and manufacturing industries and offers exper-

tise in electron microscopy, optical microscopy, materials and failure

analysis techniques, and reliability testing. The company is Grafoid’s

third advanced technology acquisition within the last 12 months, joining

Braille Battery Inc.,

Sarasota, Fla., and

Alcereco Inc.,

Kingston, Ontario.

grafoid.com.