A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 5

2 6

(<5% of expected yield strength) to the

specimen in order to properly seat it in

the grips and to also aid in pulling the

specimen straight prior to testing. A

plot of stress or force versus crosshead

or actuator displacement will typical-

ly show significant displacement for

a minimal increase in load due to the

grips and load string pulling tight (tak-

ing up system compliance). If a preload

is not applied and an extensometer is

being used, many rebar specimens will

show negative strain at the beginning

of the test as the specimen straight-

ens. Because of this and/or system

compliance, data obtained during the

preloading portion of the test is often

ignored or not recorded on the

stress-

strain

graph.

On servo-controlled systems, pre-

loading is usually done slowly using

crosshead or actuator displacement

feedback for controlling the test speed.

Controlling preloading from load, stress,

or strain feedback is not recommend-

ed as it could lead to undesirable and

rapid acceleration until the specimen is

pulled tight in the grips.

Depending on the amount of sys-

tem compliance or slack that was taken

up during the preload, it may be nec-

essary or desirable to zero the strain

measurement at the end of preloading.

However, caution must be taken to not

adversely affect overall strain measure-

ment. In either case, test results that

rely on strain from the extensometer

should be adjusted so any nonlinear

behavior at the very beginning of the

test curve does not adversely affect test

results.

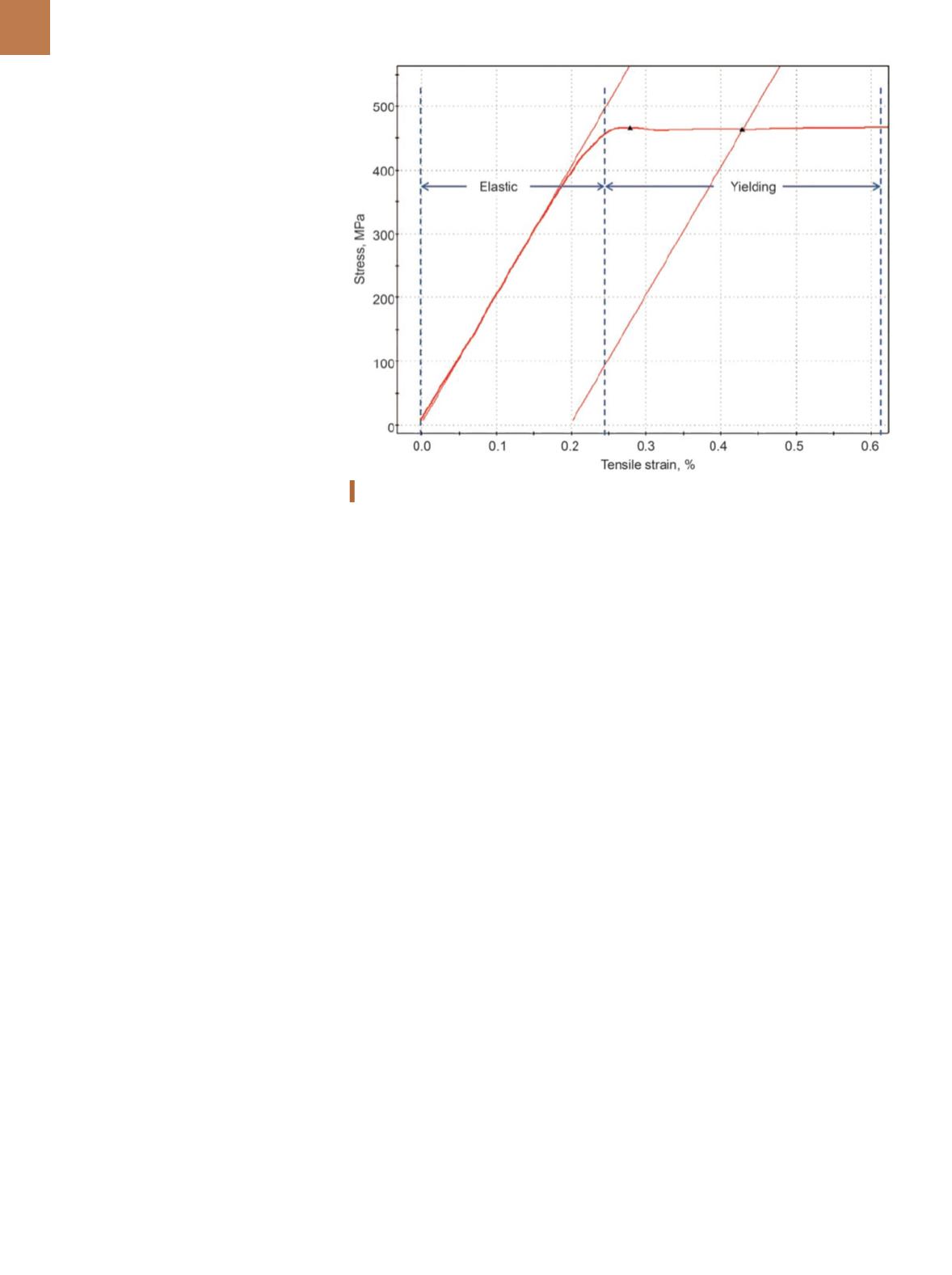

Elastic region (before yielding):

The

elastic region or straight line portion of

the test as seen on the stress-strain plot

often exhibits some initial nonlinear

behavior due to further straightening

of the rebar specimen. If using an ex-

tensometer, this may appear as slightly

negative strain at the beginning of the

test and is generally considered normal

for rebar. Depending on the standard

being followed, a variety of test control

and target speeds are allowed during

the elastic region and until the onset

of yielding. The control and associated

rate used may depend on equipment

limitations or the specific product be-

ing tested.

When running tests on servo-

controlled systems, it is important to

keep the following scenarios in mind.

If using crosshead or actuator displace-

ment control, it is generally acceptable

to use the same control and speed

through both the elastic and yielding

portions of the test. However, if stress

or strain feedback control is used, the

test must switch to crosshead or actu-

ator displacement control just before or

at the onset of yielding.

Yielding:

Once yielding begins,

many rebar grades exhibit a defined

yield point that appears as an abrupt

bend in the stress-strain test curve. It

is then followed by a period of spec-

imen elongation with little to no in-

crease in force. Because of this, servo-

controlled systems must be regulated

using crosshead or actuator displace-

ment feedback to maintain a constant

rate of travel throughout yielding. It is

important to note that using stress con-

trol during yielding will cause the test to

accelerate excessively, which is in direct

violation of the standards. This can also

cause the yield point (upper yield) to be

masked or smoothed and cause yield

strength results to be higher than ex-

pected. Likewise, strain control from an

extensometer can also become erratic

during yielding and is not recommend-

ed when testing rebar.

Plastic region after yielding:

As

standards clearly define, it is accept-

able to increase test speed after yield-

ing is complete. For servo-controlled

machines, the best way to control the

test during this final region is from

crosshead or actuator displacement

feedback (same as yielding). However,

speed can be increased according to

the standard being followed. This al-

lows the test to be completed in a short-

er period of time while still producing

acceptable and repeatable results.

A NOTE ON NOMENCLATURE

Test standards incorporate terms,

result names, and symbols to proper-

ly identify critical information sought

during testing. It is important to fully

understand this information in order

to ensure standards compliance and

proper results reporting. If testing to

multiple standards, it is also neces-

sary to understand the similarities and

Elastic and yielding regions of a rebar stress-strain curve.