A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 5

2 9

not being involved, nearly bankrupted

the company. Even so, it went into full

production in 1971. This plant became

so successful that Nucor built two more

minimills near its assembly plants in

Norfolk, Neb., and Jewett, Texas.

HEFFERNAN’S THIRD MILL

When Cargill bought out the mi-

nority shareholders of North Star Steel

in 1972, Heffernan sold his shares and

founded Co-Steel. He partnered with

Texas Enterprise to build his third mini-

mill, Chaparral Steel Co., in Midlothian,

Texas. Chaparral was equipped with

the latest technology in EAFs and con-

tinuous casters and had capacity of

200,000 tons per year, common with

these first minimills. With constant up-

grading of equipment and processes,

Chaparral produced one million tons

per year in 10 years, and two million

tons per year after another 20 years.

Through the leadership of Iverson

and Heffernan, the minimill industry

developed into 30 plants in the U.S. and

eight in Canada during the 1970s. Typ-

ical of these additional minimills was

Auburn Steel Co. in Auburn, N.Y., built in

1974 with capacity of 400,000 tons per

year. As with most of the new minimills,

it did not have an in-house market as

did Nucor with its Vulcraft Division and

Chaparral with the oil industry. Instead,

the mills were subject to the busi-

ness cycles of the steel industry. Most

of them were acquired by bigger and

more financially secure corporations.

Nucor purchased Auburn Steel and

at the same time built a Vulcraft plant

nearby to use the output. In 1975, mini-

mills had a combined output of six mil-

lion tons—a small percentage of total

steel production, which was more than

100 million tons that year.

FIRST MINIMILL FOR

FLAT PRODUCTS

A huge breakthrough in the mini

mill industry was Iverson’s new plant

dedicated to producing flat products

for Nucor. Flat products required the

highest quality steel, which was still the

mainstay of the integrated steel indus-

try. Big steel thought this area could not

be invaded by companies that relied on

scrap for feedstock. Iverson’s plant was

built in 1988 at Crawfordsville, Ind., and

the heart of the process was a new con-

tinuous casting machine from Siemens

in Germany. This enabled Nucor to cast

slabs 2 in. thick by 52 in. wide, ready to

enter the rolling mill to produce hot coil

bands for cold rolling to sheet product

used by the automotive, appliance, and

other industries. The new plant could

produce two million tons per year and

cost $1 billion to build. This was the

beginning of multimillion-ton plants,

although the term “minimills” remains

in use.

STEEL BEAMS AND

RAILROAD RAILS

At about the same time, Nucor

teamed with a Japanese company, Ya-

mato Steel Co., to produce structural

products, wide flanged beams, and rail-

road rails in a new mill at Blytheville,

Ark., with capacity of 2.8million tons per

year. This was another breakthrough

that had a great impact on the inte-

grated steel industry. The sheet mill at

Crawfordsville was immediately so suc-

cessful that Nucor built a second sheet

mill at Hickman, Iowa, with capacity

of two million tons per year. This was

the start of minimill production of flat

products and structural products that

would make significant inroads into the

primary business of integrated steel. For

25 years, Nucor led the industry in tech-

nology, production, management phi-

losophy, and market penetration. And

Nucor’s CEO, F. Kenneth Iverson, was

the most important individual in devel-

oping the U.S. minimill industry.

IVERSON LEADS INDUSTRY

F. Kenneth Iverson was born and

raised in Downers Grove, Ill. He attend-

ed Northwestern University in 1943 and

served in the Navy from 1944 until 1946,

then returned to college at Cornell Uni-

versity where he received a bachelor’s

degree in aeronautical engineering.

Iverson continued his engineering ed-

ucation with a master’s in mechanical

engineering at Purdue University. He

was a member of both ASM Internation-

al and AIME and received honorary doc-

torates from the University of Nebraska

and Purdue University. He was inducted

into the National Academy of Science-

Engineering Division in 1994 and award-

ed the National Medal of Technology.

Iverson retired in 1996 for health rea-

sons and died in 2002 at age 76.

For more information:

Charles R. Simcoe

can be reached at

crsimcoe1@gmail.com.

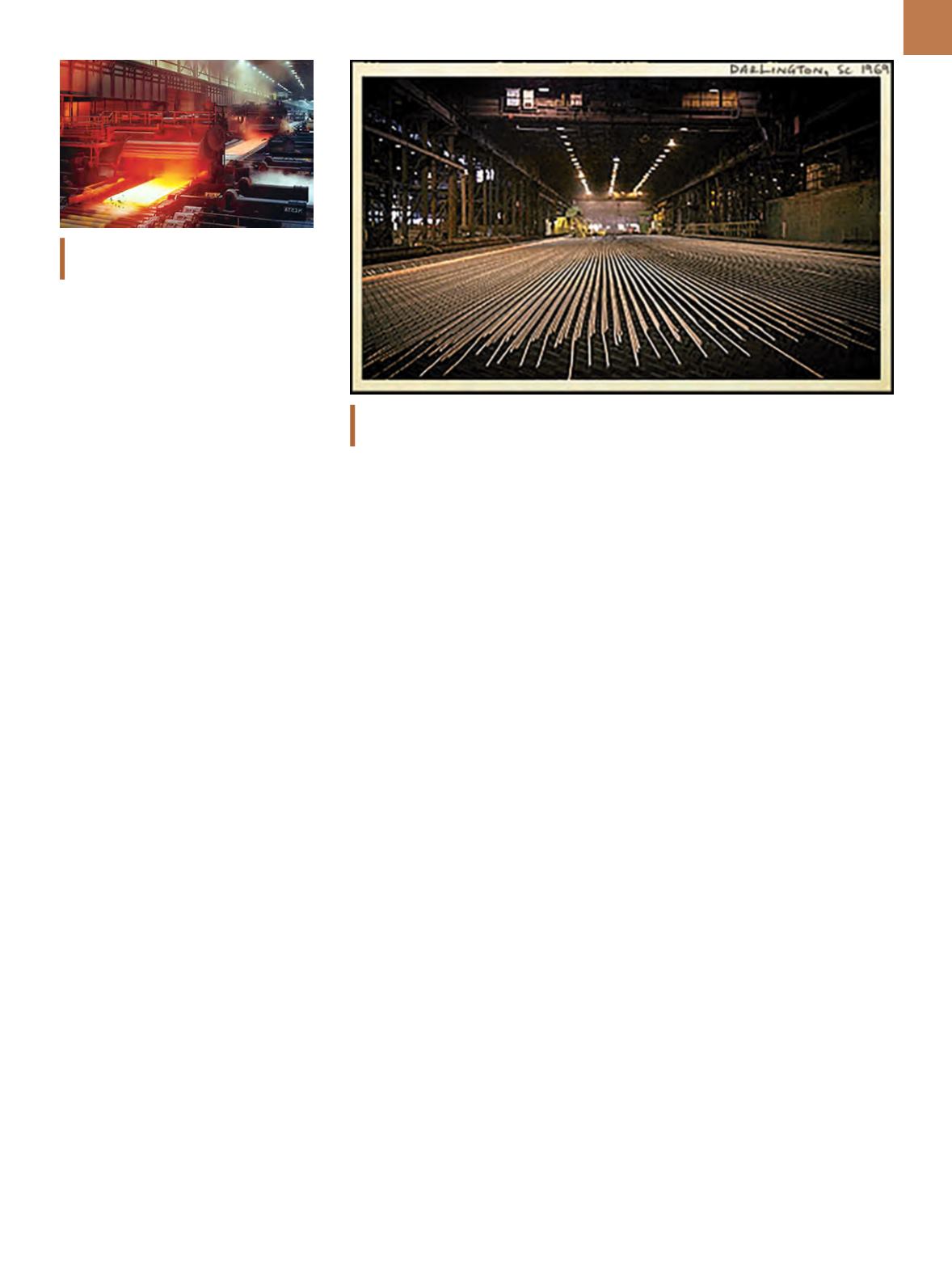

Nucor’s minimill in Darlington, S.C., had initial capacity of 200,000 tons per year. Circa 1969.

Courtesy of

nucor.com.

Hot rolling of sheets. Courtesy of Bethle-

hem/ISG and

library.fordham.edu.