A D V A N C E D M A T E R I A L S & P R O C E S S E S | J U N E 2 0 1 5

2 8

METALLURGY LANE

Metallurgy Lane, authored by ASM life member Charles R. Simcoe, is a continuing series dedicated to the early history of the U.S.

metals and materials industries along with key milestones and developments.

STEEL MINIMILLS—PART I

FROM 1900 TO 1960, THERE WAS LITTLE CHANGE IN THE STEELMAKING INDUSTRY.

STEEL MINIMILLS CAME ON THE SCENE IN THE LATE 1960s.

F

rom 1900 to 1960, there was not

much change in the steelmaking in-

dustry. Thebusinesswas dominated

by a few large companies, led by United

States Steel Corp. Steel minimills came

on the scene in the late 1960s and into

the 1970s. Besides being much smaller

than the big mills, minimills feature three

distinct factors that set them apart: Only

scrap is used in the charge for the melting

furnaces; electric arc furnaces (EAFs) are

used formelting; andsteel is solidified into

billets using continuous casting, which

feeds billets directly into the rolling mills.

Scrap had been melted in EAFs since the

early part of the 20th century, but only for

making tool steels, high alloy steels, and

stainless steelswhere scraphad tobehigh

quality to meet specifications. Scrap was

also used in large quantities in the open

hearth process to make ordinary carbon

steels and engineering alloy steels.

During the 1960s, big steel compa-

nies were changing production meth-

ods to the new basic oxygen converter

that removed carbon from the molten

metal delivered from blast furnaces.

This reduced the scrap market to very

low levels with low prices, giving further

advantage to minimills against big steel

and its capital requirements for blast

furnaces and basic oxygen converters.

At the same time, big steel was adjust-

ing to conversion to continuous cast-

ing. All these factors opened the door

for minimills to make small bars and

shapes not required to meet the speci-

fications of higher quality steel.

THE FIRST MINIMILL

The first continuous caster was

installed in 1959 at the Premium Steel

Co. in Alberta, Canada. The work was

done under Gerald Heffernan, a metal-

lurgical engineer from the University of

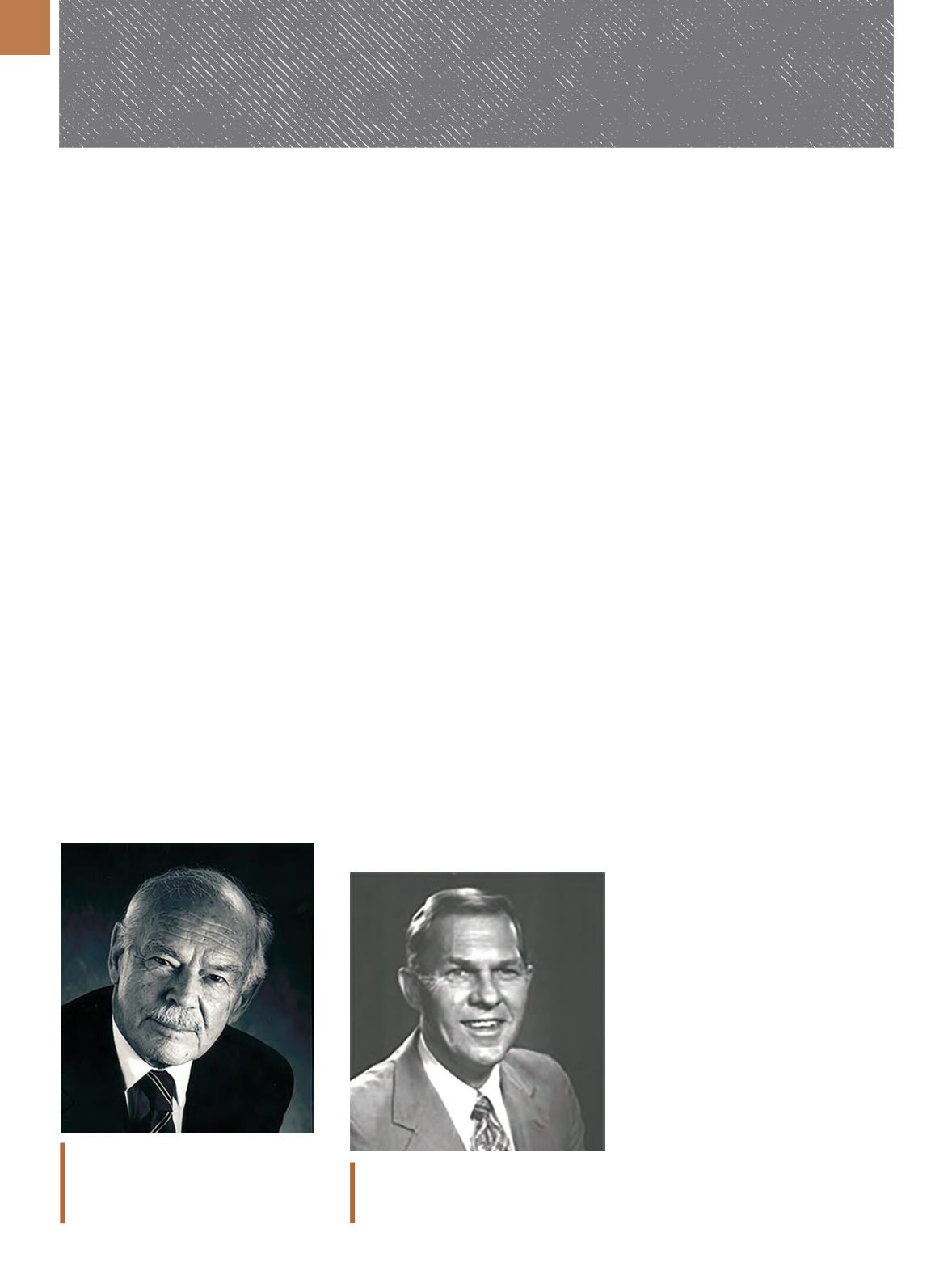

Gerald Heffernan built the first minimill

in North America in Ontario, Canada, and

the secondmill in St. Paul, Minn. Courtesy

of

amm.com.

Toronto. Only a portion of production

was put through the caster with the

rest turned into ingots, which had to be

rolled or forged into billets. Premium

Steel was purchased in 1963 by Stelco,

a big steel company in Ontario, to gain

access to this growing western market.

With his share of the sale and other fi-

nancial backing, Heffernan built the

first minimill in North America in 1964,

called Lake Ontario Steel Co. (Lasco).

Lasco was the first steel plant to put all

hot metal through a continuous caster.

Heffernan adopted a new management

philosophy, developing training for

many different job requirements with a

focus on safety. His management style

would become standard for the mini-

mill industry.

The second plant built in North

America was North Star Steel Co. in St.

Paul, Minn., also engineered by Heffer-

nan. North Star was financed by Cargill

with minority stockholders including

Heffernan. It went on stream in 1968,

producing 200,000 tons per year in bars

and shapes. One potential customer

was Vulcraft in Norfolk, Neb., a com-

pany that assembled small bars and

angle shapes into roofing beams for

shopping malls and big box buildings.

Vulcraft’s president, F. Kenneth Iver-

son, visited North Star to discuss buy-

ing steel, but came away determined

to build his own minimill to supply five

assembly plants. The parent company,

Nuclear Corp. (Nucor), selected a site

in Darlington, S.C., near one of the fab-

rication plants. This minimill became

the third in North America and had ca-

pacity of 200,000 tons per year. Startup

difficulties, combined with Heffernan

F. Kenneth Iverson, CEO of Nucor, led the

minimill industry for the first 25 years.

Courtesy of

aimehq.org.