A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S | J U N E

2 0 1 5

2 5

If a distinct

yield point

(upper yield

strength—ReH) is visible, yield strength

can be determined without an exten-

someter by reporting the stress value

at this point.

Elongation after fracture

(ASTM and ISO) and

total elongation at

maximum force

(ISO) can both be de-

termined manually after the test from

marks placed on the specimen surface.

However, there are many times

when an extensometer must be used

in order to calculate results such as

off-

set yield

(Rp 0.2) or when determining

elongation values automatically from

an extensometer instead of manually

from specimen marks. In these cas-

es, extensometers typically have large

gauge lengths compared to those used

on machined metal specimens. They

must also be robust enough to with-

stand scale falling on them during test-

ing and be able to attach to the uneven

surface of deformed bars. Depending

on the deformations, they can be at-

tached to the flat surfaces in between

deformations or on a longitudinal rib if

one exists.

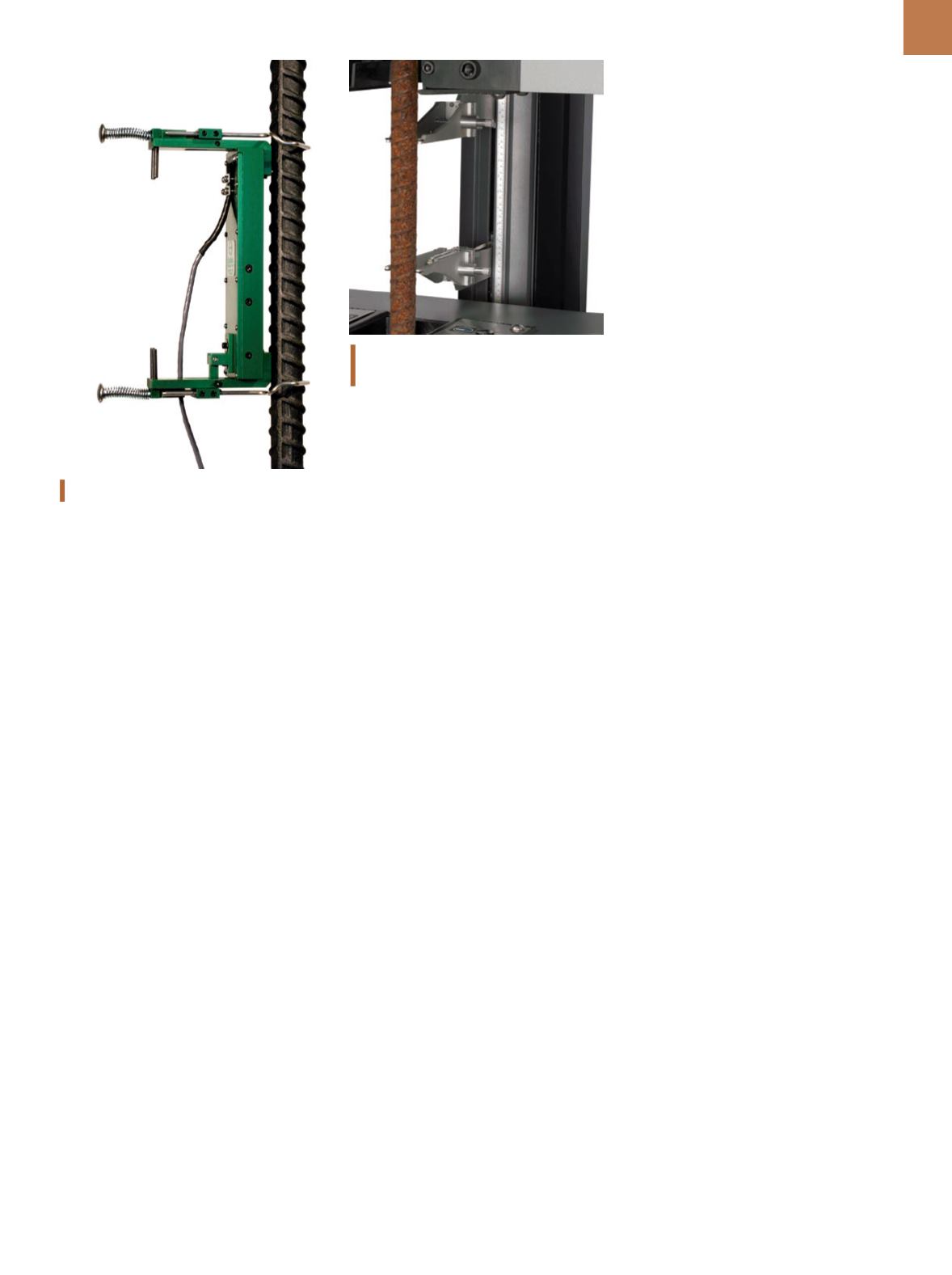

The most common extensometers

used in rebar testing are manual clip-on

style instruments attached directly to

the rebar prior to running the test. If the

instrument is not designed to remain

“on” through failure, it must be man-

ually removed after yielding occurs,

but before the specimen fails. Manu-

al instruments designed to withstand

specimen failure offer advantages, but

will likely experience faster wear of the

knife edges if frequently used through

failure.

Most manual instruments are also

designed with a fixed gauge length.

However, when testing many sizes of

rebar with varying gauge lengths, it is

necessary to have several extensome-

ters that have different lengths. Some

manual instruments are available that

can be configured for several differ-

ent gauge lengths, allowing a single

instrument to cover most common re-

quirements. Such devices require the

operator to manually configure the in-

strument properly between tests that

require a different gauge length.

Automatic

contacting

instru-

ments offer several advantages over

manual devices. Automatic removal

and attachment allow the operator to

stay out of the test space, eliminat-

ing risks associated with specimen

failures. The gauge length is set auto-

matically from software inputs and is

infinitely adjustable over the entire

travel of the instrument, allowing a

single instrument to cover all speci-

men requirements. It can also be left

on through failure if desired. Auto-

matic instruments are likely the best

solution if automatic recording of

elongation measurements is required.

TESTING SPEEDS

AND CONTROL

One challenging aspect of comply-

ing with test standards is determining

how to properly and efficiently execute

the tensile test. Despite standards pro-

viding specific details for allowable test

speeds and control modes for differ-

ent stages of the test, performing tests

properly can still be difficult. This may

be due to both standard interpretation

challenges and test equipment limita-

tions. Details that influence test con-

trol and speeds can be found scattered

throughout various sections of test

standards. Referencing more than one

standard might be necessary in order

to have all the required test setup infor-

mation. This can make it very difficult

to fully understand all aspects of the

test sequence and how to make it work

on a given testing system.

For rebar tensile testing, breaking

the test into separate stages is helpful.

This applies regardless of which test

standard is being followed. The five ba-

sic regions include:

•

Pretest

•

Preload

•

Elastic region

•

Yielding

•

Plastic region

Pretest:

During the pretest stage,

the machine is prepared for testing.

The proper grips are installed and test

opening adjustments are made. Prior

to installing the specimen, the force

(load) measurement should be set to

zero. Once the specimen is loaded into

the system, the force should not under-

go any further “zeroing” as this will af-

fect the test results. If using a manual

extensometer for measuring strain, it

should be attached to the specimen

while making sure to properly set the

knife edges at the instrument’s gauge

length. Strain measurement should

then be set to zero prior to loading the

specimen.

Preloading:

The preloading stage

is used to apply a minimal preload

AutoX750 testing #11 (36 mm) rebar on an

Instron 1500 KPX.

Manual, clip-on style rebar extensometer.