A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 5

2 9

STATIC RECRYSTALLIZATION

Recrystallization is a thermally

activated process during which new

strain-free grains replace the existing

deformed microstructure by the forma-

tion and migration of high angle grain

boundaries (HAGBs)

[17,18]

. As previously

stated, magnesium suffers from incom-

plete recrystallization as well as reten-

tion of deformation texture (basal tex-

ture). The latter is detrimental to sheet

formability, thus restricting broad ap-

plicability of magnesium alloys

[19]

. Sev-

eral factors contribute to the retention

of deformation texture in annealed ma-

terial. These include limited nucleation

sites that allow nucleation of off-basal

orientations, absence of recrystalliza-

tion within significant portions of the

material, and grain boundary bulging.

Plastic deformation of magne-

sium takes place by the activation of

many slip and twin systems. Among dif-

ferent slip systems, basal slip is consid-

ered to be the easiest mode with CRSS

~0.5 MPa

[20]

. Slip on non-basal slip sys-

tems such as prismatic <a>, pyramidal

<a>, and pyramidal <c+a> are also ob-

served

[2]

. However, the CRSS required

to initiate slip on these systems is very

high (e.g., CRSS of prism

∼

44 MPa; py-

ramidal <c+a>

∼

40 MPa

[20]

). Besides slip,

the following twin modes are frequent-

ly observed in magnesium:

Extension

twinning,

activates when <c> axis is

under tension;

contraction twinning,

activates when <c> axis is under com-

pression; and

double twinning,

formed

by contraction twinning followed by

extension twinning within the contrac-

tion twin

[21]

. The extension twinning re-

orients the grain by approximately 86°,

while contraction twinning and double

twins make a 56° and 36° angle with the

matrix, respectively.

Many scholars

[9,10,14,21]

emphasize

the significance of deformation twin-

ning in the recrystallization of magne-

siumalloys.TheworkofLevinsonetal.

[14]

illustrates the role of extension twin-

ning. They deformed AZ31 alloy sam-

ples (compressive strain = 0.05) in the

orientation that favors extension twin-

ning and then subsequently annealed

(T = 275°C). Results suggest that only

33% of the material was recrystallized

even after prolonged annealing. The

mechanism of recrystallization was re-

ported to be strain induced boundary

migration (SIBM) or grain boundary

bulging. Nonetheless, this suggests

that extension twinning plays a small

role in nucleation of strain-free grains

and subsequently retards the recrystal-

lization rate. In another study

[9]

, it is re-

ported that extension twinning has very

mobile twin boundaries; thus they opt

for thickening rather than creating the

further strain localization necessary for

recrystallization.

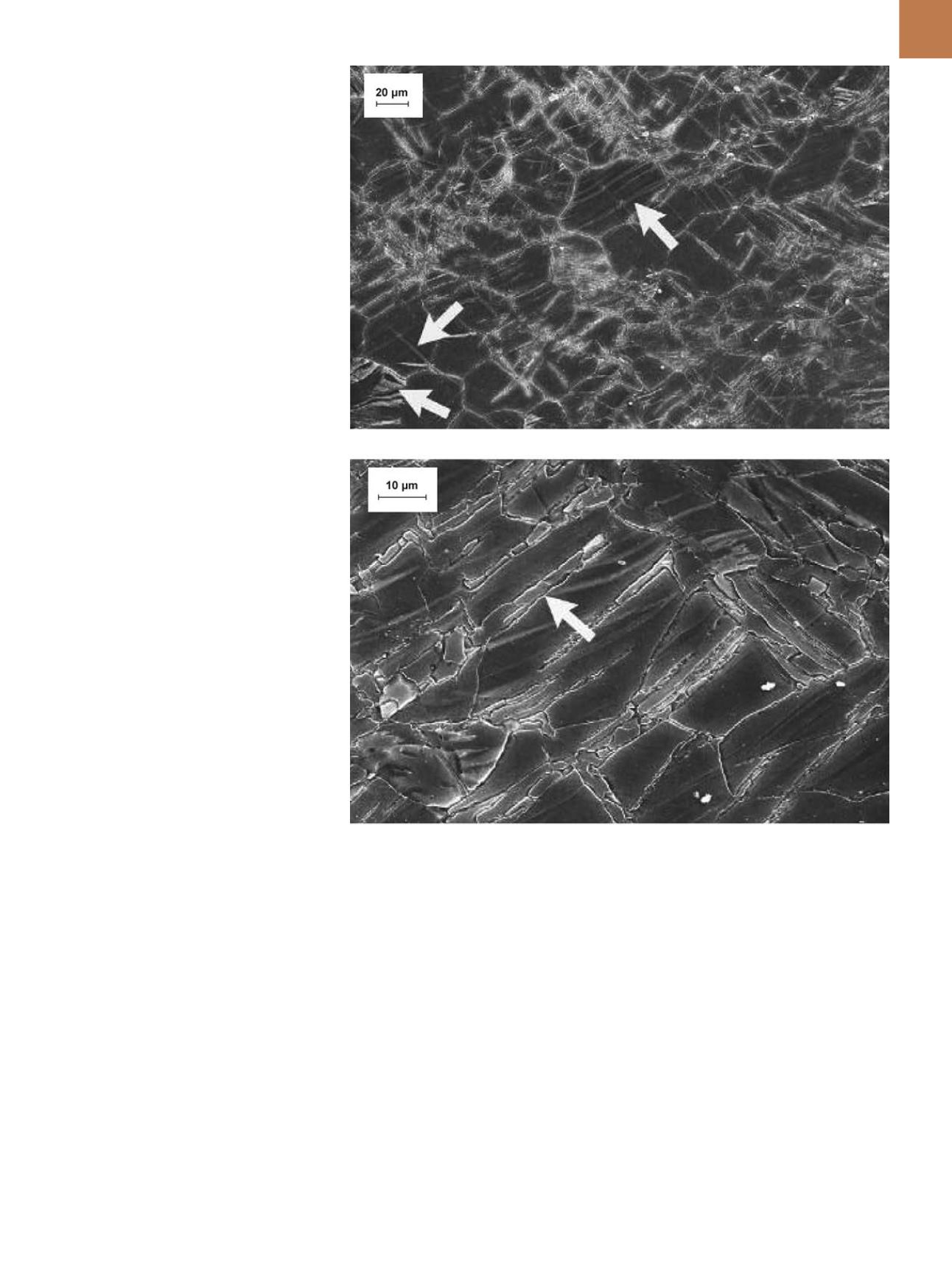

Alternatively, contraction and

double twins are very thin (Fig. 2a)

[21]

.

These are mostly formed at the later

stage of deformation (i.e.,

ε

> 5%) and

often act as a potent site for recrystal-

lization nucleation (Fig. 2b). Formation

of new recrystallized grains at contrac-

tion twins also appears in Fig. 2b. In

some instances, it is attributed to the

transformation of <a> type of glissile

dislocations into sessile dislocations

due to twinning

[22]

. This leads to ac-

cumulation of dislocations within the

twinned regions and thus increases the

Fig. 2 —

Microstructures of AZ31 magnesium alloy rolled at 100°C and then annealed at 280°C

for 10 s demonstrating (a) the presence of contraction twins and (b) nucleation at contraction

twins

[9]

.

(a)

(b)