A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 5

2 5

PRODUCT CONTAMINATION

A manufacturer of industrial-scale

bakery equipment was advised of a

problem where bread rolls produced

in its equipment were contaminated

by black marks on the bread’s surface

(Fig. 1). Relevant questions in this case

include: Is contamination on bread rolls

related to the machine, operator, work

environment, or processing variables?

Is it a health hazard? The chemical

analysis of the contaminant was deter-

mined using Fourier transform infrared

(FTIR) spectroscopic analysis.

FTIR reveals that the black marks

are associatedwithburning/overheating

of corn meal used as a release agent in

the baking process. Further investigation

determined that the conveyor belt mesh

cleaning system was not effective in re-

moving excessive cornmeal that stuck to

the mesh, which eventually burned and

stuck to the dough surface and created

the black marks. Thus it is clear that the

black marks were not due to defects in

the manufacturing process, nor a faulty

design, but were caused by inadequate

maintenance of cleaning equipment du-

ring continuous operation.

PREMATURE HEATING

ELEMENT FAILURE

Heating elements failed in a furnace

that had a specified maximum operating

temperature of 1200°F, which translat-

ed to a heating element temperature of

1825°F. The user claimed the elements

failed even though the maximum tem-

perature of the furnace was never set

higher than 1200°F. Relevant questions

regarding this failure include: Is the heat-

ing element material at fault? Is it the

heat treater’s error? Is it due to a faulty

temperature sensor/controller? Is it due

to operator error of inadvertently setting

the furnace temperature too high? How

high did the temperature go before the

element failed? The answers to these

questions were determined using optical

metallography as shown in Fig. 2.

The heating element material was

a Ni-Cr-Fe base electrical-resistor ma-

terial containing 0.014% Ti, 0.043% Nb,

0.029% C, and 0.006% N. Microalloy

precipitates coarsen or melt

[2-6]

at high

temperatures and therefore do not pre-

vent grain growth, which sometimes

leads to abnormal growth. The tem-

perature of the elements must have

exceeded 1900°F for niobium nitride/

carbonitride precipitates in this materi-

al to go into solution. The normal heat-

ing element operating temperature was

1825°F maximum, meaning the heating

element probably failed due to abnor-

mal operating conditions of excessive

furnace temperature, either due to a

faulty temperature setting or faulty tem-

perature sensor/controller.

INJECTION NOZZLE

FATIGUE FAILURE

Metal quality is an important fac-

tor in machine component failure, such

as the injection molding machine at

the center of this case. Visual and ste-

reomicroscopic examination of crack

interfaces of the component revealed

that cracking occurred due to metal fa-

tigue initiated at multiple locations on

the fillet radii of two threads on the out-

side surface (Fig. 3). Fracture surfaces

did not reveal any corrosion products,

abnormal contact patterns, or temper

colors, suggesting that component op-

erating conditions during service were

not aggressive.

Metallurgical examination indicat-

ed that the material’s heat treatment,

microstructure, hardness, and bulk

chemical composition met relevant

standards and drawing specifications.

However, a large cluster of coarse non-

metallic inclusions was observed at one

location in the microstructure (Fig. 4).

Scattered, large inclusions were also ob-

served in other locations. Electron mi-

croscopy of the fracture surface reveals

a large number of secondary-phase par-

ticles and inclusions clustered around

crack initiation regions. Most of these

particles contained Cr, C, S, and Si, sug-

gesting that chromium carbide precipi-

tated on preexisting silicate and sulfide

inclusions.

One of the particles had a glassy

appearance and contained significant

amounts of C, K, and Ca. This particle

is most likely from the ironmaking op-

eration in the blast furnace. Sources for

K are iron ore and coke ash, while Ca

comes from the basic flux, such as lime

(CaO) used for desulfurizing iron. Large

clustered inclusions in a material signifi-

cantly decrease its fatigue resistance and

toughness by serving as crack initiation

(a)

(b)

(c)

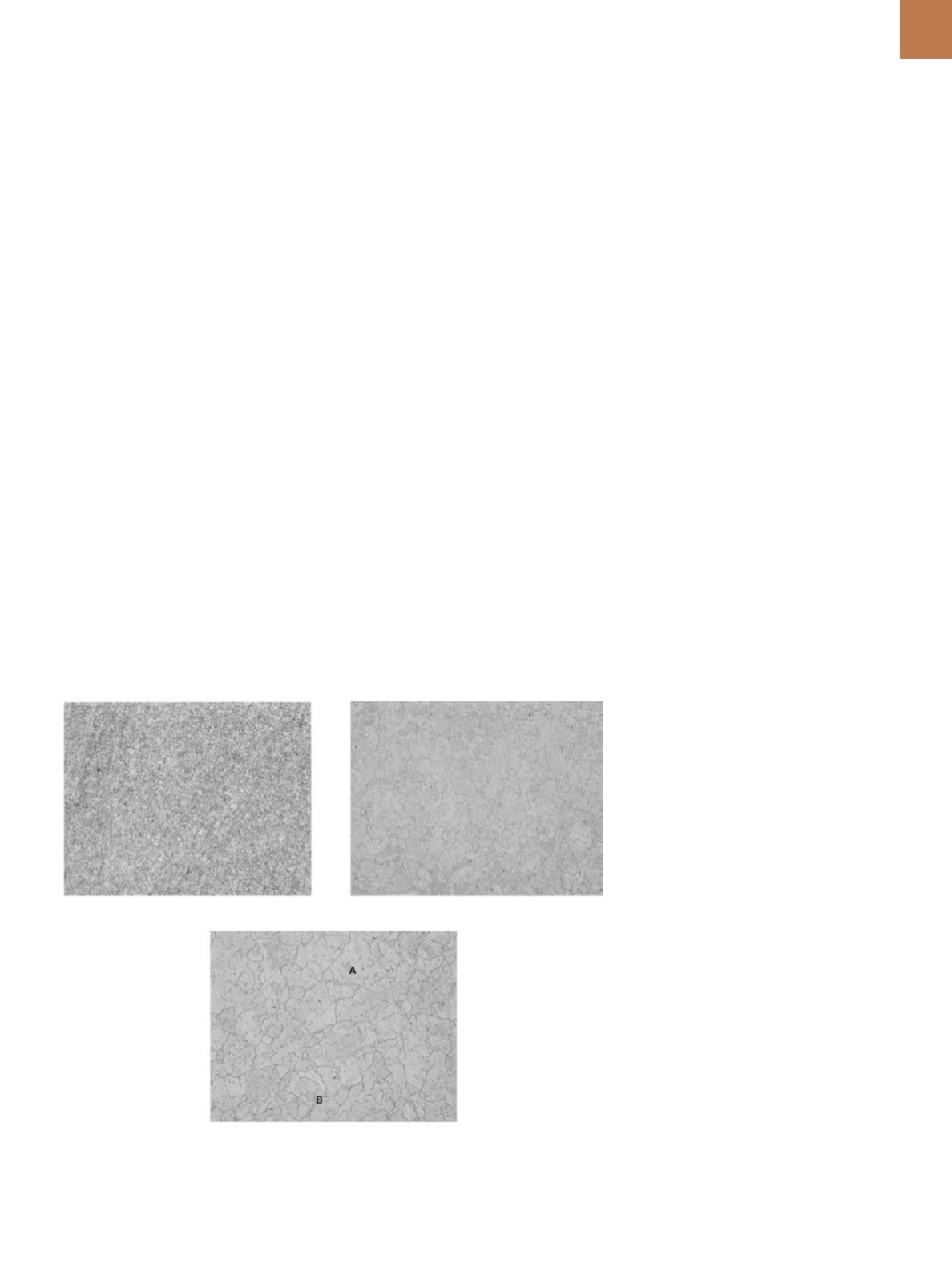

Fig. 2 —

(a) Microstructure of original heating element showing fine-grained austenite, mag:

100×; (b) microstructure of used heating element showing coarse-grained austenite, mag: 100x;

and (c) example of a mixedmicrostructure and abnormal grain growth in the failed heating

element (A = coarse grains, B = fine grains; mag: 200×). Etchant was modified Marble’s reagent

[1]

.