A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 5

3 1

takes place quite rapidly and is often

responsible for incomplete recrystalli-

zation. The kinetics can be slowed by

adding specific alloying elements that

can lower the SFE. A greater understand-

ing of the role of solute elements and

second phase particles on the recovery

kinetics of magnesium alloys is needed.

Preferred sites for recrystallization

in magnesium are the grain boundaries,

contraction/double twins, twin-twin in-

tersections, and twin-grain boundary

interactions. Among these, the latter

three provide an opportunity to weaken

the detrimental basal texture. A care-

ful increase in the density of such sites

would not only address the problem of

incomplete recrystallization, but also

help in weakening the basal texture in

magnesium alloys. This can be achieved

by adding the solute elements and pre-

cipitates, and changing the strain path.

More detailed research is required so

these factors can be systematically

probed to obtain the desired micro-

structure. The potential of PSN in mag-

nesium alloys has not been explored

to a fuller extent. Additional work is

required to investigate the effect of dis-

persoids’ size, spacing, and volume frac-

tion on the recrystallization process.

Magnesium also suffers from sec-

ondary recrystallization. Better control

10. S. Liang, M.A. thesis, McMaster Uni-

versity, Hamilton, Ontario, 2012.

11. S. Sandl

ö

bes, et al.,

Acta Mater.,

Vol 60, p 3011-3021, 2012.

12. N. Stanford,

Mat. Sci. Eng. A,

Vol 565,

p 469-475, 2013.

13. X. Yang, et al.,

J. Mater. Sci.,

Vol 47,

p 2823-30, 2012.

14. A. Levinson, et al.,

Acta Mater.,

Vol 61, p 5966-5978, 2013.

15. P. Okrutny, M. Sc. thesis, McMaster

University, Hamilton, Ontario, 2010.

16. C-W. Yang, Chapter 13,

Materials

Science - Advanced Topics.

17. D. Raabe,

Recovery and Recrystal-

lization: Phenomena, Physics, Models,

Simulation

, 2014.

18. F.J. Humphreys and M. Hatherly,

Recrystallization and Related Annealing

Phenomena

, Second Edition, Elsevier.

19. X.Y. Lou, et al.,

Int. J. Plasticity,

Vol 23, p 44-86, 2007.

20. J. Jain, Ph.D. thesis, Materials

Engineering, The University of British

Columbia, 2010.

21. C.W. Su, L. Lu, and M.O. Lai,

Philos.

Mag.,

2008.

22. B. Bhattacharya, Ph.D. thesis, Mc-

Master University, Hamilton, Ontario,

2006.

23. S. Sandlöbes, et al.,

Mater. Sci.

Forum,

Vol 690, p 202-205, 2011.

24. N. Stanford and M.R. Barnett,

Mat.

Sci. Eng. A,

Vol 516, p 226-234, 2009.

25. J.D. Robson, N. Stanford, M.R. Bar-

nett,

Scripta Mater.,

Vol 63, p 823-826,

2010.

26. J. Jain, et al.,

Scripta Mater.,

Vol 62,

p 301-304, 201-0.

27. J.D. Robson, D.T. Henry, and B.

Davis,

Acta Mater.,

Vol 57, p 2739-2747,

2009.

28. J.D. Robson, N. Stanford, M.R. Bar-

nett,

Acta Mater.,

Vol 59, p 1945-1956,

2011.

29. D.K. Xu, et al.,

J. Alloy Compd.,

Vol 426, p 155-161, 2006.

30. M.T. Perez-Prado and O.A. Ruano,

Scripta Mater.,

Vol 46, p 149-155, 2002.

31. M.T. Perez-Prado and O.A. Ruano,

Scripta Mater.,

Vol 48, p 59-64, 2003.

32. J. Ma, et al.,

Mater. and Design,

Vol 47, p 505-509, 2013.

of microstructure and therefore me-

chanical properties will be key in decid-

ing the future of magnesium and its al-

loys. The effect of solute elements and

second phase particles on grain growth

needs to be investigated in detail.

For more information:

Dr. Jayant Jain

is an assistant professor, Department

of Applied Mechanics, Indian Institute

of Technology, Delhi, 91.11.26591246,

jayantj@am.iitd.ac.in.

References

1. M.R. Stoudt,

JOM—J. Min. Met. Mat. S.,

Vol 60, p 56, 2008.

2. P.G. Partridge,

Met. Rev.,

Inst. Metals,

Vol 118, p 169, 1967.

3. J. Koike, et al.,

Acta Mater.,

Vol 51,

p 2055-2065, 2003.

4. S.E. Ion, F.J. Humphreys, and S.H.

White,

Acta Metall.,

Vol 30, p 1909-1919,

1982.

5. M.T. Perez-Prado, et al.,

Scripta Ma-

ter.,

Vol 50, p 661-665, 2004.

6. J.A. delValle and O.A. Ruano,

Mat.

Sci. Eng. A,

Vol 487, p 473-480, 2008.

7. Y. Xu, L. Hua, and Y. Sun,

J. Alloy Com-

pd.,

Vol 580, p 262-269, 2013.

8. J. Jain, W.J. Poole, and C.W. Sinclair,

Magnesium Technology,

2006.

9. X. Li, et al.,

Mat. Sci. Eng. A,

Vol 517,

p 160-169, 2009.

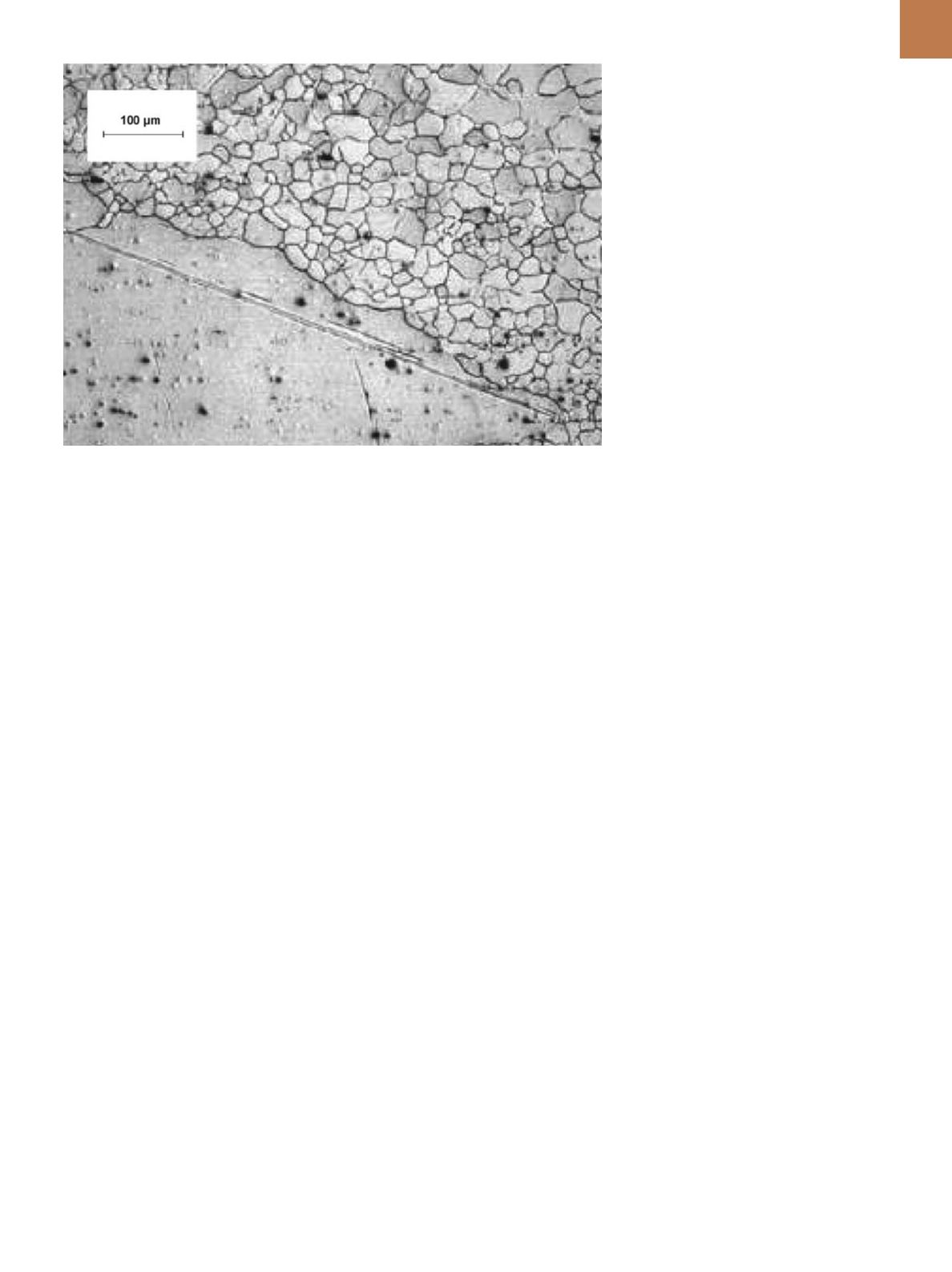

Fig. 3 —

The microstructure of the outer surface of an extruded AZ31 magnesium alloy showing

the occurrence of abnormal grain growth when annealed to 450°C for three hours

[30]

.