A D V A N C E D M A T E R I A L S & P R O C E S S E S | A P R I L 2 0 1 5

2 6

sites. Therefore, it was concluded that

fatigue cracking of the component was

facilitated by inadequate steel quality,

i.e., lack of cleanliness.

SHEAR OVERLOAD FAILURE

OF GAS PIPELINE BRACKET

A leaking underground gas pipe-

line resulted in a house explosion, caus-

ing grievous personal injury. The exca-

vated pipeline revealed that two pieces

separated, causing a massive gas leak.

Extensive failure investigations boiled

down to one question: Did the failure

occur over a period of time or was it due

to a single catastrophic event? Analysis

of the fracture surfaces of the brackets

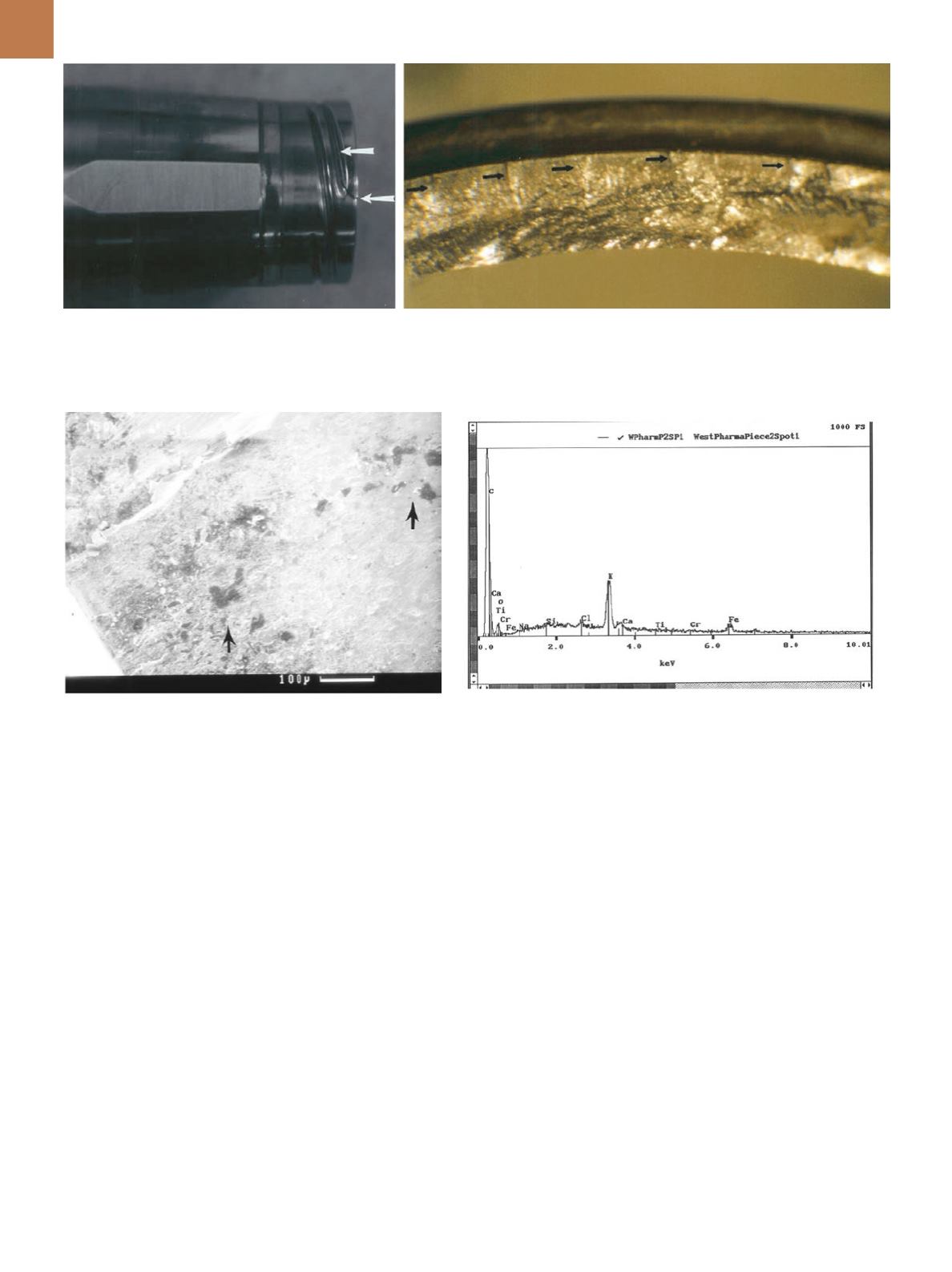

Fig. 3 —

(a) Cracked injection-molding machine component, and (b) stereomicrograph of the crack interface revealing a multiple origin fatigue

failure suggested by ratchet marks (black arrows).

(a)

(b)

(a)

(b)

Fig. 4 —

(a) SEM image at failure initiation zone with a ratchet showing clusters of inclusions and precipitates (arrows), mag: 160×, and (b) energy

dispersive spectroscopy (EDS) spectrum of an inclusion indicates peaks for C, K, Ca, Cl, and Cr. This particle has probably come from the ironmaking

operation in the blast furnace where sources for K are iron ore and coke ash while Ca is from the basic flux, such as lime (CaO), used for desulfuriza-

tion of iron ore.

holding the pipes together provide the

answer. Figure 5 shows the fractogra-

phy of one of the brackets, clearly indi-

cating a sudden shear overload failure.

It was eventually concluded that the

pipeline pieces separated from each

other due a landslide event in the val-

ley not far from the location where the

pipeline was buried, and the failure was

mainly caused by the natural disaster

rather than human error.

~AM&P

For more Information:

P.A. Mano-

har is an associate professor, Robert

Morris University, Engineering Depart-

ment, John Jay 119B, 6001 University

Blvd., Moon Township, PA 15108-1189,

manohar@rmu.edu, www.rmu.edu.Acknowledgment

The author thanks Modern Indus-

tries Inc., Erie, Pa., for permission to

publish the photographs. The work was

carried out at the company’s Pittsburgh

laboratory.

References

1. G.F. Vander Voort and H.M. James,

Wrought Heat-Resistant Alloys,

Metallog-

raphy and Microstructures

, Vol 9,

ASMHandbook

, ASM International,

p 305-329.

2. K. Narita, Physical Chemistry of the

Group IVa (Ti, Zr), Va (V, Nb, Ta) and the

Rare Earth Elements in Steel,

Trans.

ISIJ

, Vol 15, p 145, 1975.