A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 5

2 3

applications, and can also perform ad-

vanced applications such as strain con-

trol and dynamic testing.

Flexibility of applications:

One of

the most beneficial features of non-

contacting extensometry is its ability

to be used for almost any application.

This flexibility allows adaptation to var-

ious tests with minimal changes to base

equipment. Equally, non-contacting ex-

tensometers work well in quality con-

trol environments where repeatability

and robustness are key.

Various lenses:

Most video and la-

ser extensometers have interchange-

able lenses. The different lenses dictate

the field of view of the strain measure-

ment—how much of the test space can

be seen by the camera. Smaller field-

of-view lenses are typically used when

very high-accuracy measurements are

required, such as inmetals and compos-

ites tests, whereas larger field-of-view

lenses are used for high-elongation

tests, such as films and elastomers.

Ease of use:

Many commercially

available non-contacting extensometers

require minimal operator intervention

during the test, as they are usually inte-

grated into the test method automatical-

ly. Operators only need tomarkmaterials

with dots, lines, speckle, or other surface

patterns to be picked up by the camera.

Temperature chamber use:

Because

non-contacting extensometers do not

contact specimens, they are suitable for

both high and low temperature testing.

They can be attached to chambers that

are fitted with windows, with minimal

compromise to strain signal accuracy.

Robustness:

There are no moving

parts on most non-contacting exten-

someters, so there is little wear and

tear on the device itself. Robust devices

need less servicing over their lifetime

and can last for many years before be-

ing repaired or replaced, maximizing

the uptime of testing operations.

LOOKING FORWARD

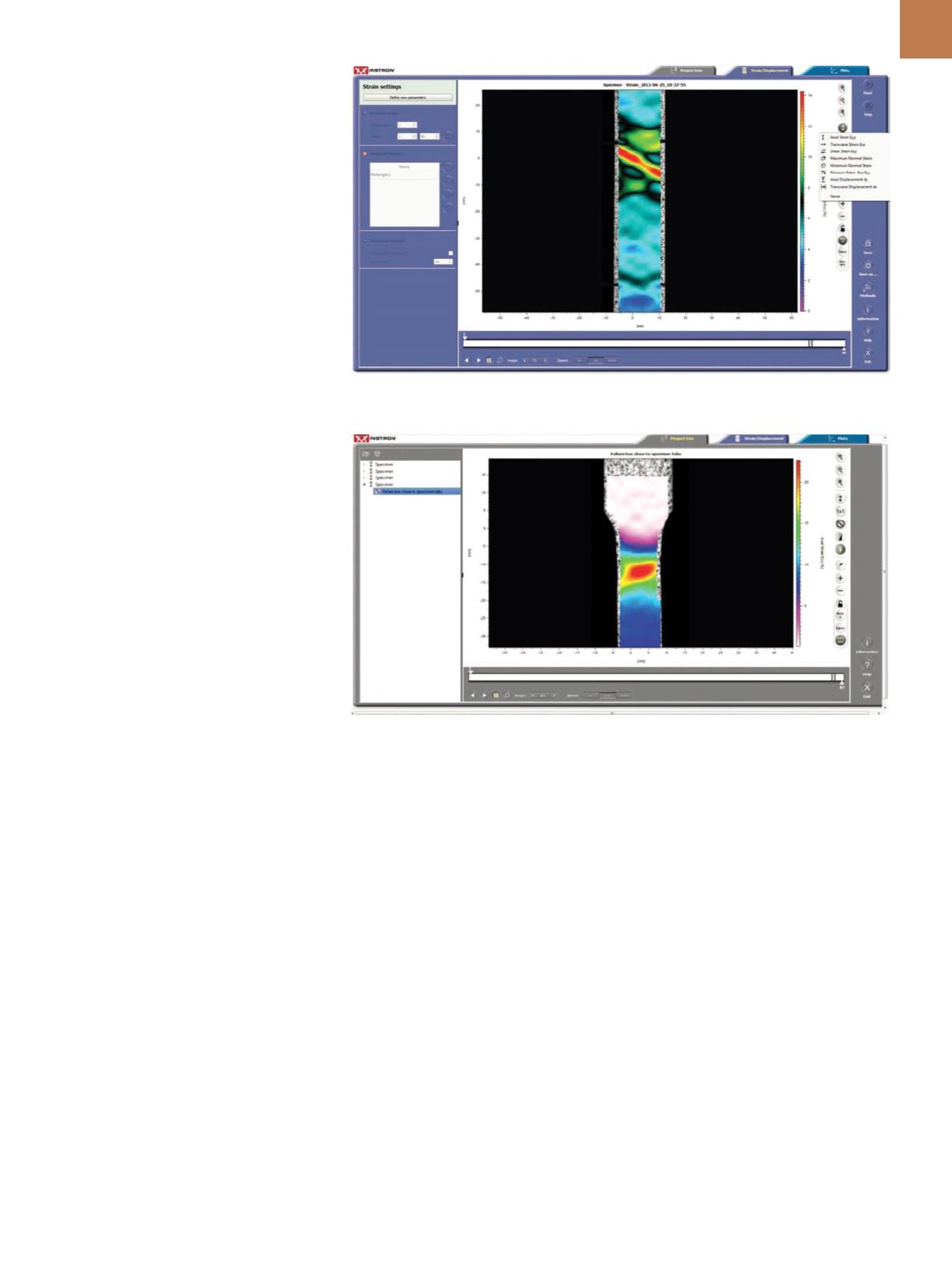

Non-contacting strain devices are

not limited to simple elongation and

deformation measurements. Recently,

video extensometers have been used to

collect images for digital image correla-

tion (DIC). DIC is an optical technique

that has been used within research

environments for more than 30 years

and allows strain to be measured over

the entire surface of a specimen or com-

ponent. Sequential images are taken

during a test and DIC software analyzes

these post-test to extrapolate displace-

ment data by tracking changes to a

pattern either applied to the specimen

or occurring naturally in the material.

This allows a strain map, similar to an

FEA-analysis or thermal image, to be

shown for the entire surface with single

camera systems working in 2D and two

camera, or stereo, systems allowing

measurements in 3D.

As DIC provides operators with

strain data across the full field of the

specimen surface, as opposed to only

elongation between two points from

a traditional extensometer, it can also

provide more information such as

discontinuous yielding, shear strain,

localized necking, and can locate strain

hot spots. This allows FEA models to be

validated with real products and weak-

nesses in design and common failure

points to be discovered. DIC also en-

ables strains to be found that an exten-

someter would not be able to discover,

and is a valuable teaching tool as well.

Although DIC has been a popular

standalone research technique for years,

it was only recently that its capabilities

have been integrated with commercially

available video extensometers with a sim-

plified user interface, making this power-

ful analytical tool available for any capa-

blematerials testing operator.

~AM&P

For more information:

Elena Mangano

is market development specialist, In-

stron, 825 University Ave., Norwood, MA

02062, 800.877.6674,

elena_mangano@ instron.com.Fig. 3 —

Digital image correlation analysis shows localized strain on a metal tensile specimen.

Fig. 4 —

Digital image correlation analysis shows localized strain on a plastic tensile specimen.