A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

A P R I L

2 0 1 5

3 3

resistance. This presentation will review

studies that characterize the surface

properties of Nitinol and the impact on

the material’s corrosion behavior.

Engineering Nitinol Thin Films for

Medical Devices—A Process Review

Andreas Schuessler,

Admedes Schuessler GmbH, Germany

Nitinol sputter deposition tech-

nology was recently proposed as an

innovative manufacturing process re-

sulting in superior fatigue performance

and consistent material characteristics

up to 85

μ

m thickness. Developing new

and cost effective micro components

and devices from sputter deposition,

however, requires dedicated and ad-

vanced design rules. A number of ad-

vanced engineering processes for using

Nitinol sputter technology for micro ac-

tuators and medical devices will be re-

viewed. The session will also highlight a

number of enhanced micro joining and

femto-laser technologies for various

types of system building concepts and

product applications.

Additive Manufacturing of Nitinol

Fixation Hardware for Reconstructing

Mandibular Segmental Defects

Ahmadreza Jahad,

The University of Toledo, Ohio

The goal of this project is to ad-

vance the scientific knowledge of Niti-

nol by investigating production of 3D

shapes using selective laser sintering.

The grouphas full access toa rangeof fa-

cilities at the Nitinol Commercialization

Accelerator for conducting research.

Results of this investigation are expect-

ed to create a paradigm shift in Niti-

nol research. Functional devices with

shape memory and superelastic prop-

erties with versatile geometries are fun-

damental to open innovation frontiers

in disciplines such as medical devices

and aerospace actuators. Mohammad

Elahinia will present with Jahad.

EDUCATION COURSE

Nitinol workshop

Monday, May 18

9:00 a.m.–4:30 p.m.

Organized by Alan R. Pelton, this optional all-day education course on Niti-

nol technology will provide attendees with a fundamental understanding of shape

memory and superelasticity. Course topics include:

•

How Nitinol works: Basic thermal and mechanical properties

•

How to make Nitinol: Processing to optimize in vivo performance of medical

devices

•

How to design with Nitinol: Strategies on design of medical devices

•

How Nitinol performs: Insight into fatigue and corrosion properties

This course is an excellent opportunity to strengthen understanding of shape

memory and superelastic materials in advance of the technical sessions.

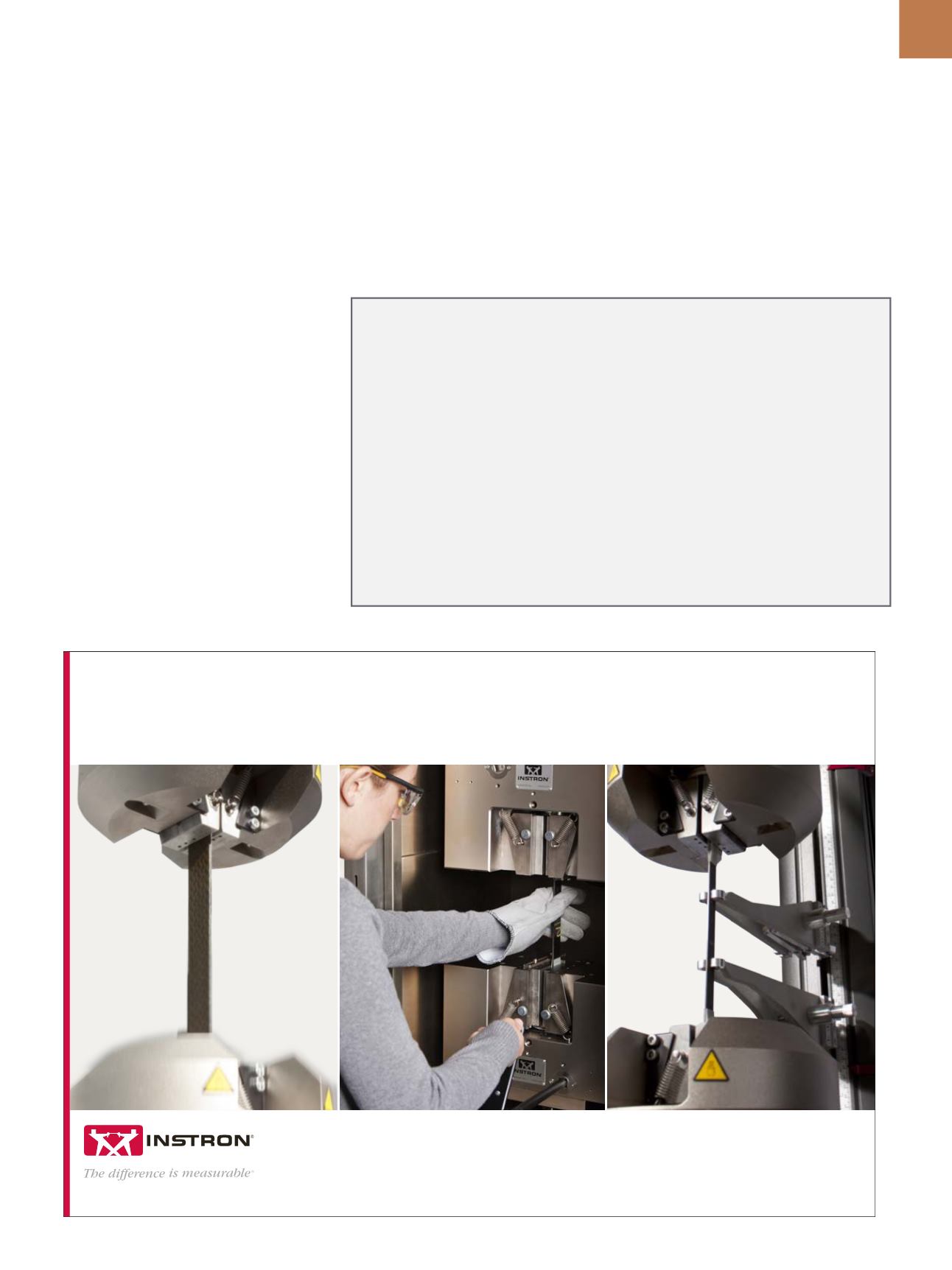

825 University Avenue, Norwood, MA 02062 | 1.800.564.8378 | go.instron.com/Trust When Composites Performance is Critical… TRUST Instron The latest Instron ® composites testing solutions enhance the scope, quality, and efficiency of your tests.