Implant coating promotes bone growth

Researchers at Uppsala University, Sweden, developed

a responsive coating for implants to improve their inte-

gration into bone and to prevent rejection. Neutron scat-

tering experiments at the Institut Laue-Langevin (ILL),

France, show how a protein that promotes bone growth

binds to this surface and can be released in a controlled

way. Gels made by modifying hyaluronan, a biological

molecule, can coat implants. Research shows the coated

titanium surfaces can bind protein molecules that pro-

mote bone formation. These can be released slowly once

the surface comes in contact with a solution of calcium

ions. This process stimulates bone growth on implants.

The gel layers, a few millionths of a millimeter thick, were

characterized using neutron reflection at ILL, providing a

detailed surface image. BMP-2, the protein that encour-

ages bone growth, was bound to the gel. The protein layer

was stable in water, but could be released slowly by adding

solutions containing calcium, a process that was observed

in real time using neutron reflection to track the amount

of protein at the surface.

www.uu.se/en.Coating offers grease-free lubrication and corrosion protection

Researchers at the INM – Leibniz Institute for New Materials, Germany, developed a

functional coating that lubricates without grease and protects against corrosion at the same

time. It is suitable as a coating for metals and metal alloys such as steel, aluminum, or mag-

nesium. “We incorporated platelet-like solid lubricants and platelet-like particles in a

binder. When this mixture is applied to a surface, it produces a well-ordered structure in

which these various particles are arranged in a roof tile pattern,” says Carsten Becker-Will-

inger, head of the Nanomers Program Division. This forms a so-called transfer film be-

tween the low-friction coating and the object through which surfaces can slide with

minimal friction. “The particular mixture ratio means that our composite has a very low

coefficient of friction. If we only used a solid lubricant, the coefficient of friction would be

considerably higher,” says Becker-Willinger.

www.inm-gmbh.de/en.Moth eyeballs inspire low-glare coating

Work by University of California Irvine scientists could reduce glare from solar panels

and electronic displays, as well as dangerous glints on military weapons. “We found a very

simple process and a tiny bit of gold can turn a transparent film black,” says chemistry pro-

fessor Robert Corn. The team was initially worried when they noticed what appeared to be

soot on a flexible film designed to coat various products. Via painstaking tests, however,

they realized they accidentally discovered a way to fabricate a surface capable of eliminat-

ing glare. The material can also keep grime in raindrops and other moisture from sticking.

A repeating pattern of cones modeled on moth eyeballs at the nanoscale was etched on

Teflon and other nonstick surfaces. A thin layer of gold was

then applied over the cones and the shine from the gold

and any light reflecting onto it was all but obliterated. The

material is also highly hydrophobic.

For more information:

Robert Corn, 949.824.1746,

rcorn@uci.edu,

uci.edu.

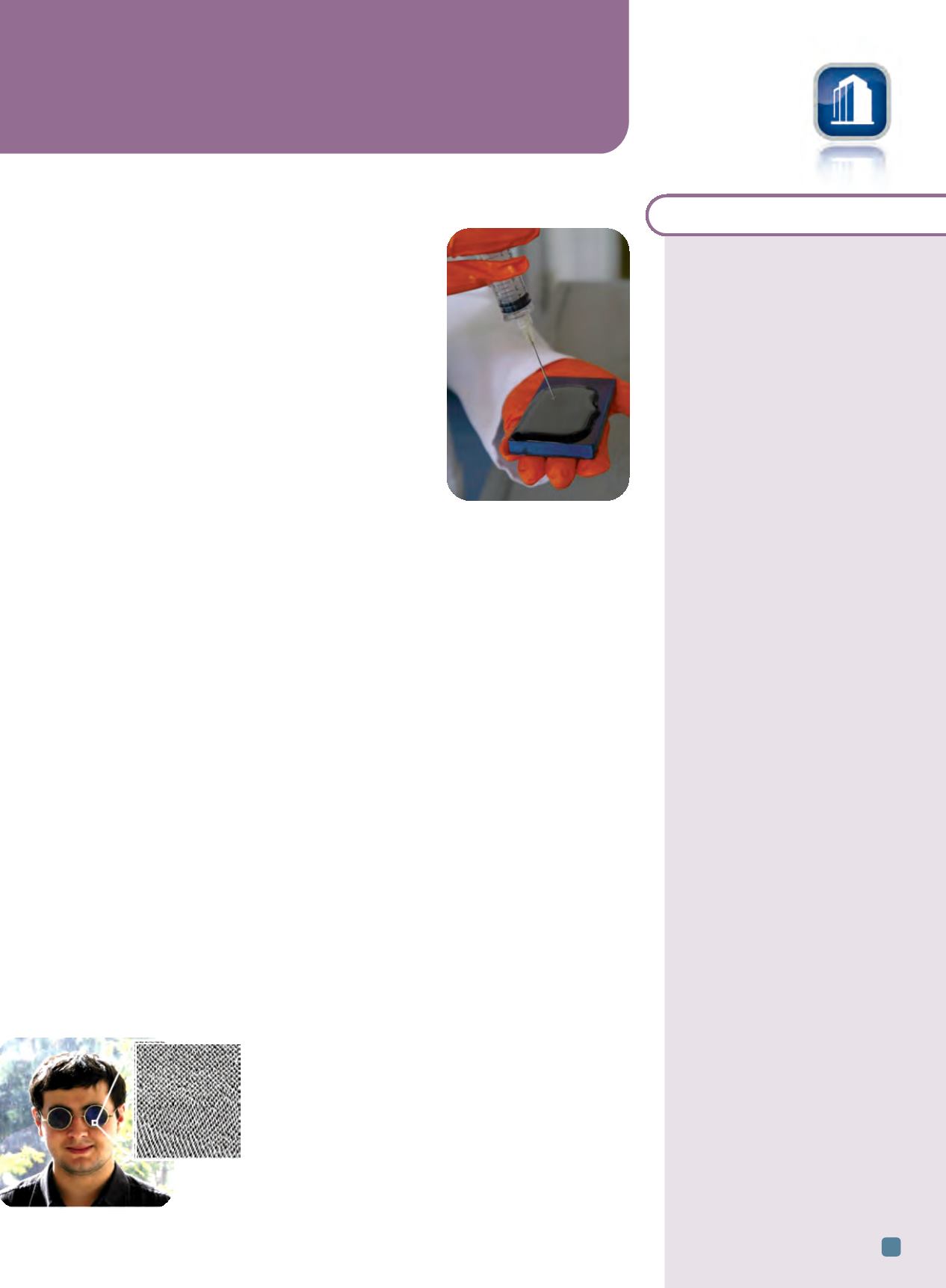

UC Irvine undergraduate chemistry student George Auwaijan

sports a pair of sunglasses coated with a new material invented by

researchers that mimics the pattern of moth eyeballs to reduce glare.

Courtesy of Gabriel Loget/UC Irvine.

ADVANCED MATERIALS & PROCESSES •

JUNE 2014

15

S

URFACE

E

NGINEERING

news

industry

briefs

Rice University,

Houston,

scientists mixed very low

concentrations of diamond

particles (roughly 6 nm in

diameter) with mineral oil to test

the nanofluid’s thermal

conductivity and how temperature

affects its viscosity. They found it

to be much better than nanofluids

that contain higher amounts of

oxide, nitride or carbide ceramics,

metals, semiconductors, carbon

nanotubes, and other composite

materials. In tests, researchers

dispersed nanodiamonds in

mineral oil and found that a very

small concentration—one-tenth of

a percent by weight—raised the

thermal conductivity of the oil by

70% at 373°K (211°F).

rice.edu.

NEI Corp.,

Somerset, N.J.,

introduced NANOMYTE SuperCN

Plus, a functionally graded coating

that imparts superhydrophobic

properties to the underlying

substrate while providing greater

abrasion resistance compared to

existing superhydrophobic

coatings. The coating consists of a

hard and abrasion-resistant outer

layer that transitions to a softer

material closer to the substrate.

Due to its graded structure, the

coating maintains its

superhydrophobicity and high

contact angle even after moderate

damage. Additionally, it exhibits

good adhesion to the substrate.

neicorporation.com.

Researchers at the

University of

Arkansas

report achieving the

highest efficiency ever in a 9 mm

2

solar cell made of gallium

arsenide. After coating cufflink-

sized cells with a thin layer of zinc

oxide, the team reached a

conversion efficiency of 14%. A

small array of these cells—as few

as nine to 12—generates enough

energy for small LEDs and other

devices. Better yet, surface

modification can be scaled up and

cells can be packaged in large

arrays of panels to power large

devices such as homes, satellites,

or even spacecraft.

uark.edu.

A gel-coated titanium surface

binds proteins that promote

bone formation. Courtesy of

Ida Berts.