news

industry

briefs

To research further into different

areas of advanced materials,

including the possibility of

invisibility cloaks, £2.5 million is

being invested by the UK’s

Engineering and Physical

Sciences Research Council.

Concepts in fields such as acoustic

metamaterials and thermal

cloaking will be applied in order to

engineer designer metamaterials

with specific properties. Leading

UK scientists based at

Imperial

College London,

the

University of

Liverpool,

and

Liverpool John

Moores University

will work on

the five-year study.

www.epsrc.ac.uk.

The University of Chicago’s

Institute for Molecular

Engineering

will build a major

new facility for nanoscale

fabrication within the

William

Eckhardt Research Center,

supported by a $15 million gift

from the

Pritzker Foundation.

In

recognition of the gift, the 12,000-

sq-ft building will be named the

Pritzker Nanofabrication Facility.

With advanced tools and enough

room for a wide range of projects,

the space will support work on

new applications in computing,

health care, communications,

smart materials, and more.

uchicago.edu.

Illustration of high-speed optical

networks that could enable

quantum information processing

and communication. Courtesy of

Peter Allen.

Electron beam builds teeny tiny nanowires

Junhao Lin, a Vanderbilt University Ph.D. student

and visiting scientist at Oak Ridge National Laboratory

(ORNL), Tenn., discovered how to use a finely focused

beam of electrons to create some of the tiniest wires ever

made. The flexible metallic wires are only three atoms

wide—one-thousandth the width of microscopic wires

used to connect the transistors in today’s integrated cir-

cuits. According to collaborators, the technique is an ex-

citing way to manipulate matter at the nanoscale and

should boost efforts to create electronic circuits out of

atomic monolayers, the thinnest possible form factor for

solid objects.

The tiny wires are made of a special family of semiconducting materials that naturally

formmonolayers, called transition-metal dichalcogenides (TMDCs). TMDCs are made by

combining molybdenum or tungsten with either sulfur or selenium. Atomic monolayers

have exceptional strength, flexibility, transparency, and high electron mobility. Interest in

them was sparked in 2004 by the discovery of an easy way to create graphene. Yet despite

graphene’s promising properties, converting it into useful devices is problematic, which is

why scientists have turned to other monolayer materials like the TMDCs. Other research

groups have already created functioning transistors and flash memory gates made of

TMDC materials. Now, the discovery of how to make wires provides the means for inter-

connecting these basic elements.

vanderbilt.edu.

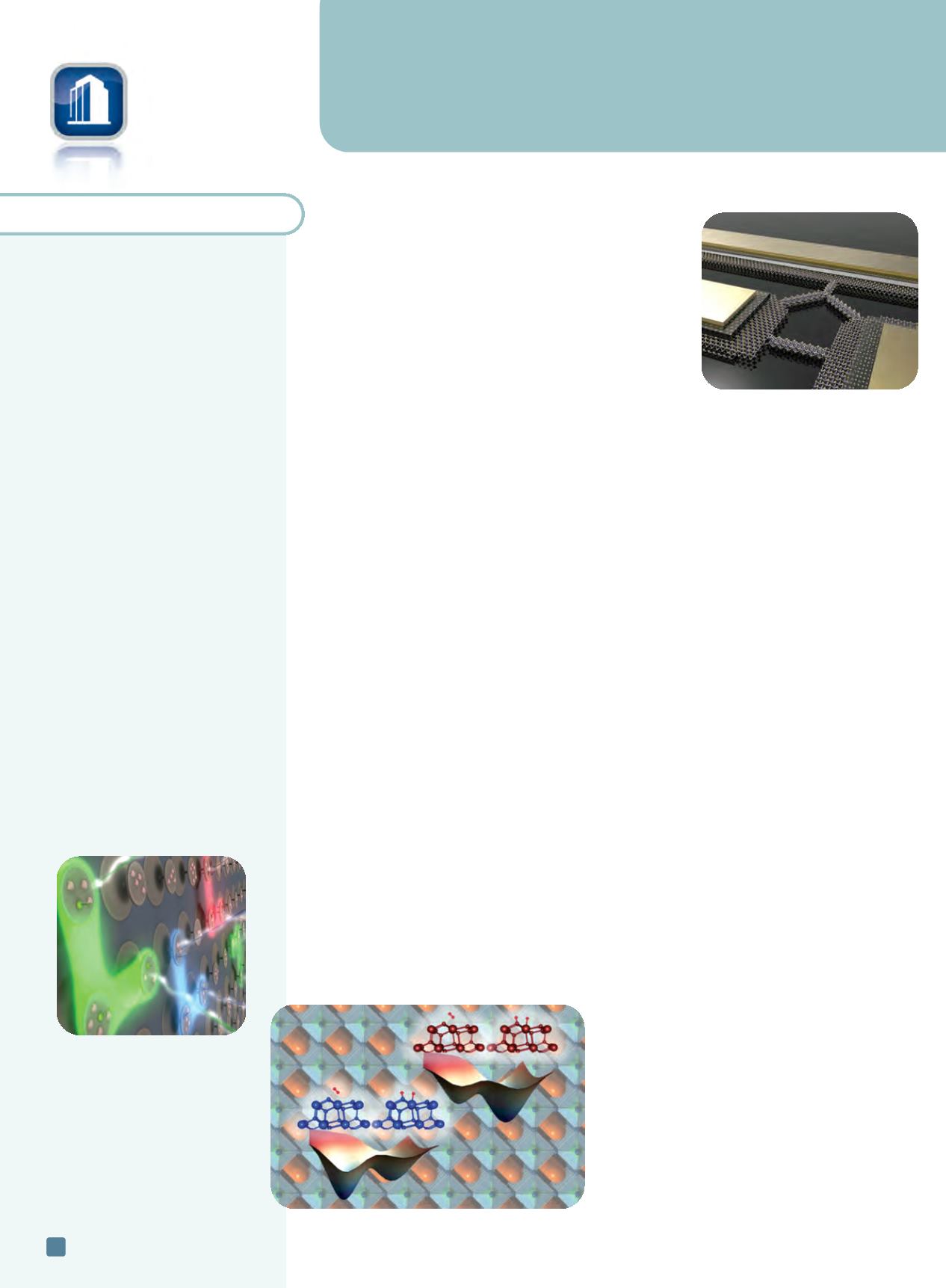

Strain engineering enables new areas of materials research

In the ongoing search for new materials for fuel cells, batteries, photovoltaics, separa-

tion membranes, and electronic devices, one newer approach involves applying and man-

aging stresses within known materials to give them dramatically different properties.

Known as

elastic strain engineering,

the discipline was long envisioned by theorists, but

only arose formally about 20 years ago. It initially focused on pure silicon, whose tensile

stress improves the speed of charges in integrated circuits, and on metal catalysts, where

tensile stress improves surface reactivity.

“Traditionally, materials are made by changing compositions and structures, but we

now recognize that strain is an additional parameter that can be changed, instead of look-

ing for new compositions,” says Bilge Yildiz, associate professor of nuclear science and en-

gineering at Massachusetts Institute of Technology (Cambridge), one of the pioneers of

this approach. “Even though we are dealing with small amounts of strain—displacing atoms

within a structure by only a few percent—the effects can be exponential.”

Putting these theoretical improvements into practice in a device, however, is a major

challenge. Yildiz focuses on improving diffusion and reaction rates in metal oxides, which

could affect how fast an energy storage or conversion device, such as a battery, works. Ox-

ides are more complex than pure silicon or metal catalysts, says Yildiz, but offer a much

larger array of potential material properties.

For example, oxides including cobaltites and

manganites, used as fuel-cell electrodes, show

performance gains through stretching and

straining.

For more information: Bilge Yildiz,

617.324.4009,

byildiz@mit.edu,

mit.edu.

Illustration background shows a perovskite oxide

structure. By straining this material, the energy

barrier to surface reactions is reduced. Energy

barriers are shown by 3D graphs in foreground

images. Courtesy of Mostafa Youssef, Lixin Sun,

and Bilge Yildiz.

ADVANCED MATERIALS & PROCESSES •

JUNE 2014

12

E

MERGING

T

ECHNOLOGY

Molecular model of nanowires

made of TMDCs.