edfas.org

19

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 19 NO. 1

was 0.3 normal HIO

3

in water. The second was 0.3 normal

HIO

3

in 50% HNO

3

. The etch results, at different fuming

nitric acid to corrosion-inhibitor mix ratios, are shown in

Fig. 6 through 11.

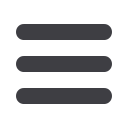

All electron micrograph images were taken with the

Hitachi High Technologies TM-3030Plus tabletop scan-

ning electron microscope. No sample preparation was

used, to negate the possibility of any sample-preparation

artifacts. As can be seen, there is no detectable difference

in wire quality. Along with the increasing amount of etch

debris with lower amounts of introduced water was a

corresponding increase in the size of the etched cavity.

As the encapsulant-removal rate increases, so does the

debris load of the etchant and the greater the amount left

on the wires and die surface.

DISCUSSION

The data presented in Ref 1 indicate a fairly narrow

range of process parameters that produce undamaged

silver bond wires. Bond pull strengths dropped with

increasing etch time, higher and lower mix ratios, higher

etch temperatures, and greater age of the premixed

etchant.

Using a corrosion inhibitor that was directly injected

into the fuming nitric acid flow path in an automatic

decapsulator significantly increases the available range

of process parameters. Varying the etchant-to-inhibitor

ratio by a factor of 2 produced no detectable difference

inwire quality. The inhibitor has a nearly infinite shelf life.

Initial evaluations of effects from increased etch

times and higher etch temperatures indicate significant

increases in the useful range of these parameters as well,

as shown in Fig. 12 and 13.

All of theparts shown in thefigures use silver alloywire.

It has been found in additional evaluations that pure silver

wires require a higher-concentration inhibitor solution. An

iodic acid solution at 1.0 M concentration reproduces the

results shown with pure silver bond wires.

CONCLUSION

Silver bond wires can be protected from damage

during acid decapsulation by the injection of a corrosion

inhibitor into the acid stream. The use of a 0.3M iodic acid

solution provides protection of silver alloy wires over a

wide range of process parameters, including etch time,

etch temperature, and the amount of inhibitor injected.

Additionally, a 1.0 M iodic acid solution will provide the

same protection for pure silver wires. This solution also

has a very long shelf life and is relatively safe.

Fig. 11

40:1 iodic acid in dilute nitric acid

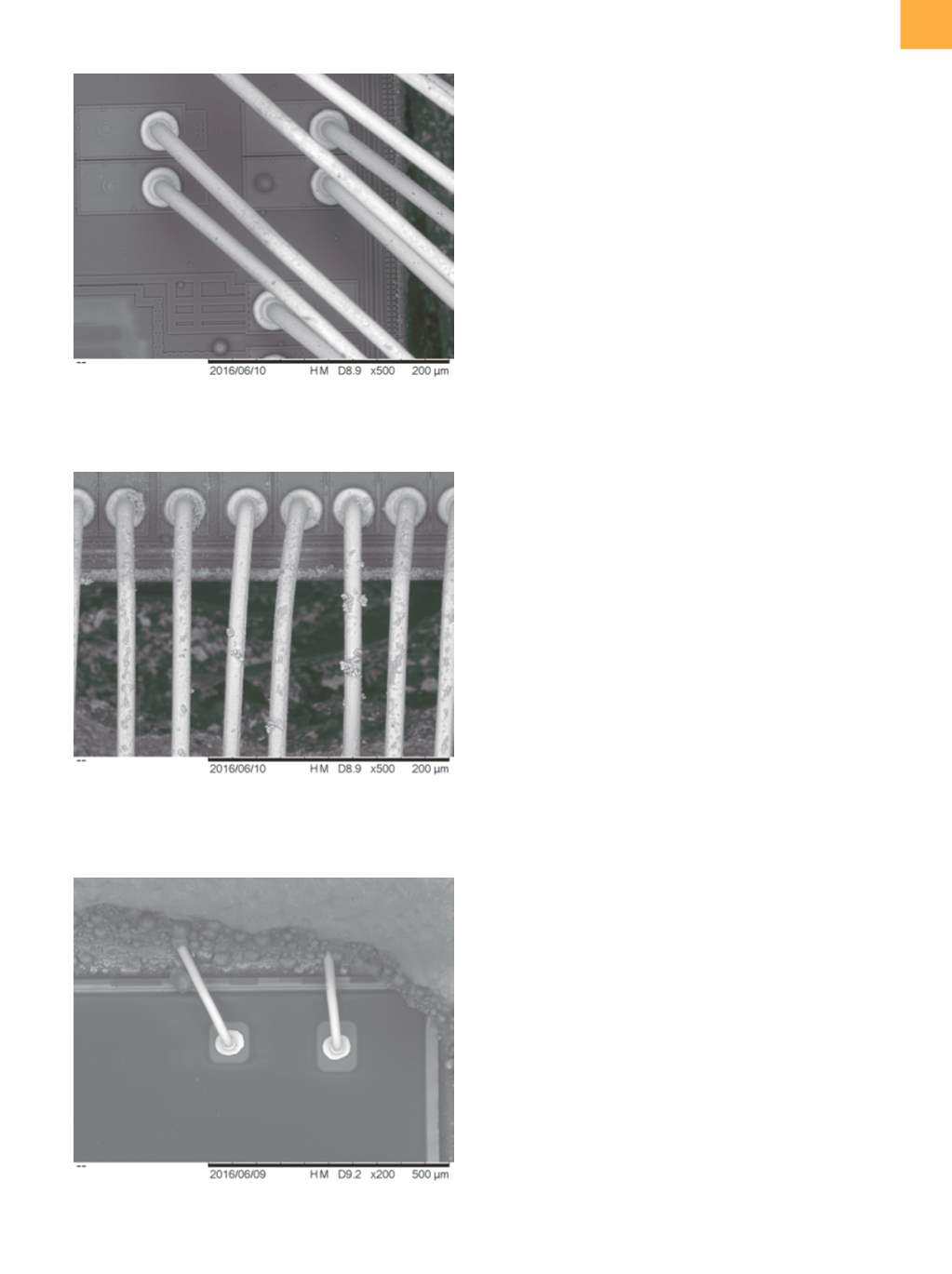

Fig. 12

Etched using iodic acid at 50 °C

Fig. 13

Etched using iodic acid with 360 s etch time