edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 4

4

EDFAAO (2016) 4:4-14

1537-0755/$19.00 ©ASM International

®

LVI AND LVP APPLICATIONS IN IN-LINE SCAN CHAIN

FAILURE ANALYSIS

Zhigang Song and Laura Safran, Globalfoundries

zhigang.song@globalfoundries.comL

aser voltage imaging (LVI) has the unique capability

of mapping the periodic signal in a device under

test (DUT). It is very suitable for scan chain diagno-

sis because data propagation through the scan chain is

clocked with a periodic signal. Thus, LVI can easily iden-

tify the broken point for a scan chain failure, whether its

defect is in the data pathor in the clock path. Laser voltage

probing (LVP) involves acquiring the waveform in a time

domain froma particular point, such as the signal broken

point identified by LVI, and a reference point. This can

further confirm the failure and help with understanding

the failure signature. This article discusses combining

these two techniques in an in-line scan chain logic macro

diagnosis, which has greatly improved the failure analysis

success rate.

INTRODUCTION

Historically, static random access memory (SRAM)

yields have been the only qualification metrics during

technologydevelopment, and consequently, failure analy-

sis of SRAM is themain feedback for process improvement

and yield learning.

[1,2]

This is because the high density and

small feature size of SRAMmake its yield very sensitive to

process variation, and the failing bit cells can be precisely

localized for physical failure analysis. As microelectronic

technology progresses in the nanometer realm, logic

circuits and structures are also becoming dense and

sensitive to process variation. Logic failures may also

have root causes different from SRAM failure. If these

technology weak points for logic circuits are not detected

and resolved during the technology development stage,

they will greatly affect the product manufacturing yield

ramp, leading to longer design time tomarket. Moreover,

analysis of logic failure in the product is much more dif-

ficult and time-consuming, involving tester-based fault

isolation

[3,4]

and software-based scandiagnosis.

[5,6]

Thus, it

is very important to have an in-line scan chain logicmacro

implemented for early detection of the logic circuit weak

points during technology development. Furthermore,

LVI’s unique capability to map the periodic signal

[7-9]

in

a DUT makes it a great diagnostic technique for scan

chain failure, whether the scan chain failure is due to a

clock issue or an issue with the latch itself. In addition,

LVP probing

[10-13]

can further confirm the failure identi-

fied by LVI. The combination of LVI and LVP application in

scan chain diagnosis has improved the in-line scan chain

logic failure analysis success rate to that of SRAM failure

analysis. This article reviews the LVI and LVP technique

principles and their unique capabilities, then describes

an in-line scan chain logic macro, and finally presents

three case studies of LVI and LVP applications in in-line

scan chain failure analysis.

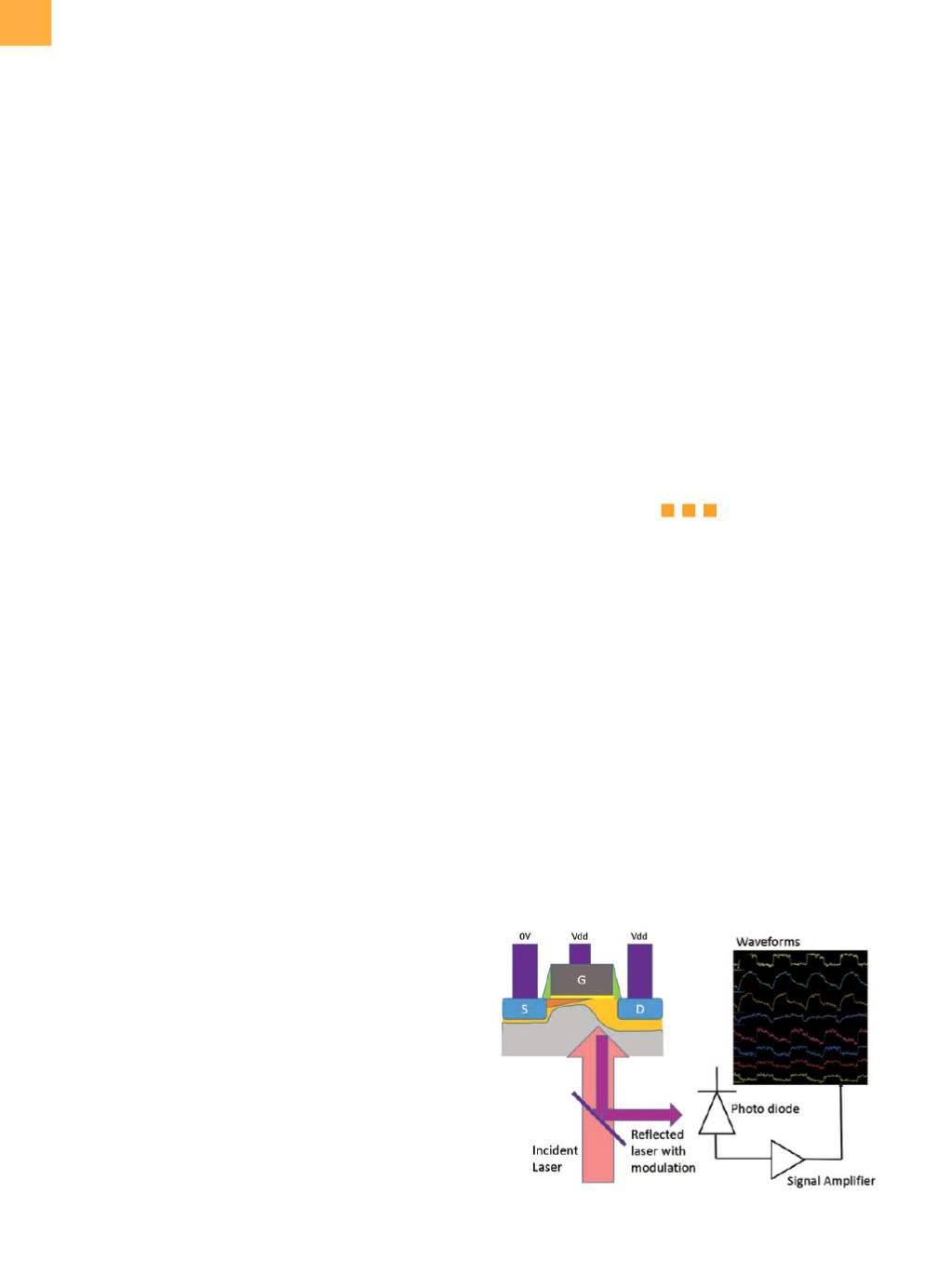

LVI AND LVP TECHNIQUE REVIEW

Laser voltage probing

[10-13]

employs a near-infrared

laser beam shining on the transistor active area through

“THE COMBINATION OF LVI AND LVP

APPLICATION IN SCAN CHAIN DIAGNOSIS

HAS IMPROVED THE IN-LINE SCAN CHAIN

LOGIC FAILURE ANALYSIS SUCCESS RATE

TO THAT OF SRAM FAILURE ANALYSIS. ”

Fig. 1

LVP schematic