edfas.org

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 3

12

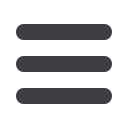

with the rest “electrically filtered.” Figure 4(c) shows the

overlay image. This result demonstrates the feasibility of

the technology.

Additionally, it should be noted that the criteria for

matching can be determined by the user. For example, a

trigger pulse can also be generated as long as one of the

current fail vectors matches to any of the failed vectors

in the reference signature. In this case, more signals are

expected to be observed in the image as compared to

an exact match, because the comparison scheme is less

stringent.

SOFTWARE APPROACH

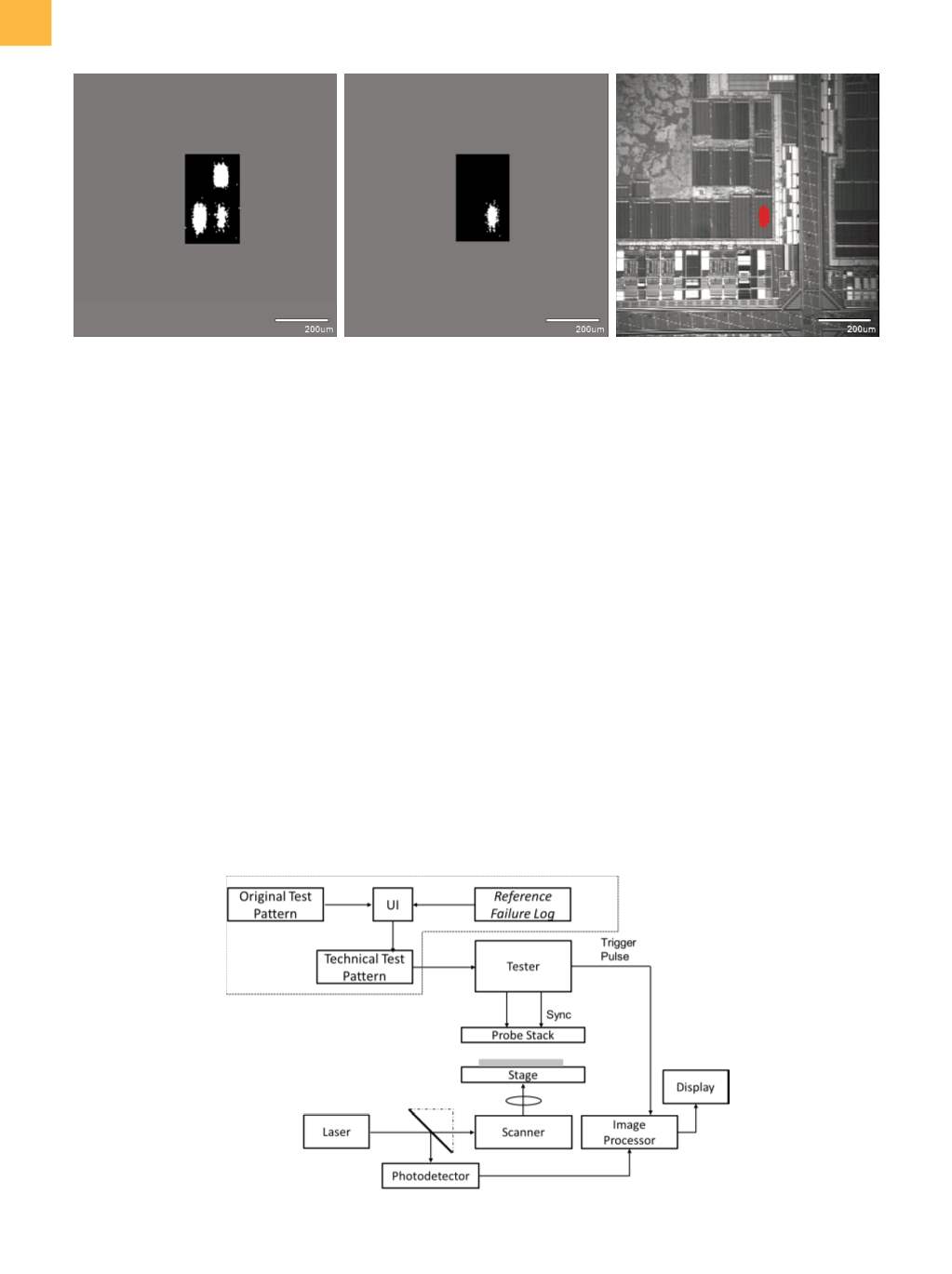

Another approach to realize EeLADA is illustrated by

the block diagram in Fig. 5. Unlike the hardware approach,

there is no comparator logic involved to assess a match

situation. Instead, a graphical user interface (GUI) receives

the original test vectors as well as details of the failing

signature to generate a technical test pattern dedicated

for defect localization. To explain the methodology,

consider a simple case of a failure signature consisting

of only a failed vector that corresponds to a certain fail

cycle and pin. Assuming this specific compare vector is

failing, a “High” is expected; that is, it attains a “Low” on

the test. The original vectors that correspond to the failing

signature are inverted. In this case, instead of expecting

a “High,” the test now expects a “Low” for this compare

vector to pass. Therefore, the test will fail by default when

the technical test pattern is employed. As the laser induces

LADA signals that give rise to failing compare vectors

other than the inverted vector, the test state remains

unchanged. Conversely, when the LADA signal matches

the failing signature, there is a state change to pass, and a

match trigger signal is provided directly from the tester to

the image processor. Similar to the hardware implemen-

tation, the match criteria are, in fact, controllable. In this

approach, they are determined by the way the original

pattern is manipulated to produce the technical pattern.

Figure 6 shows a screenshot of the GUI dashboard. The UI

enables a user toprovide inputs tomanipulate the original

(a)

(b)

(c)

Fig. 4

(a) Conventional LADA signals. (b) EeLADA signals. (c) Overlay image

Fig. 5

Block diagram representing software implementation of EeLADA