edfas.org

edfas.org

5

ELECTRONIC DEVICE FAILURE ANALYSIS | VOLUME 18 NO. 2

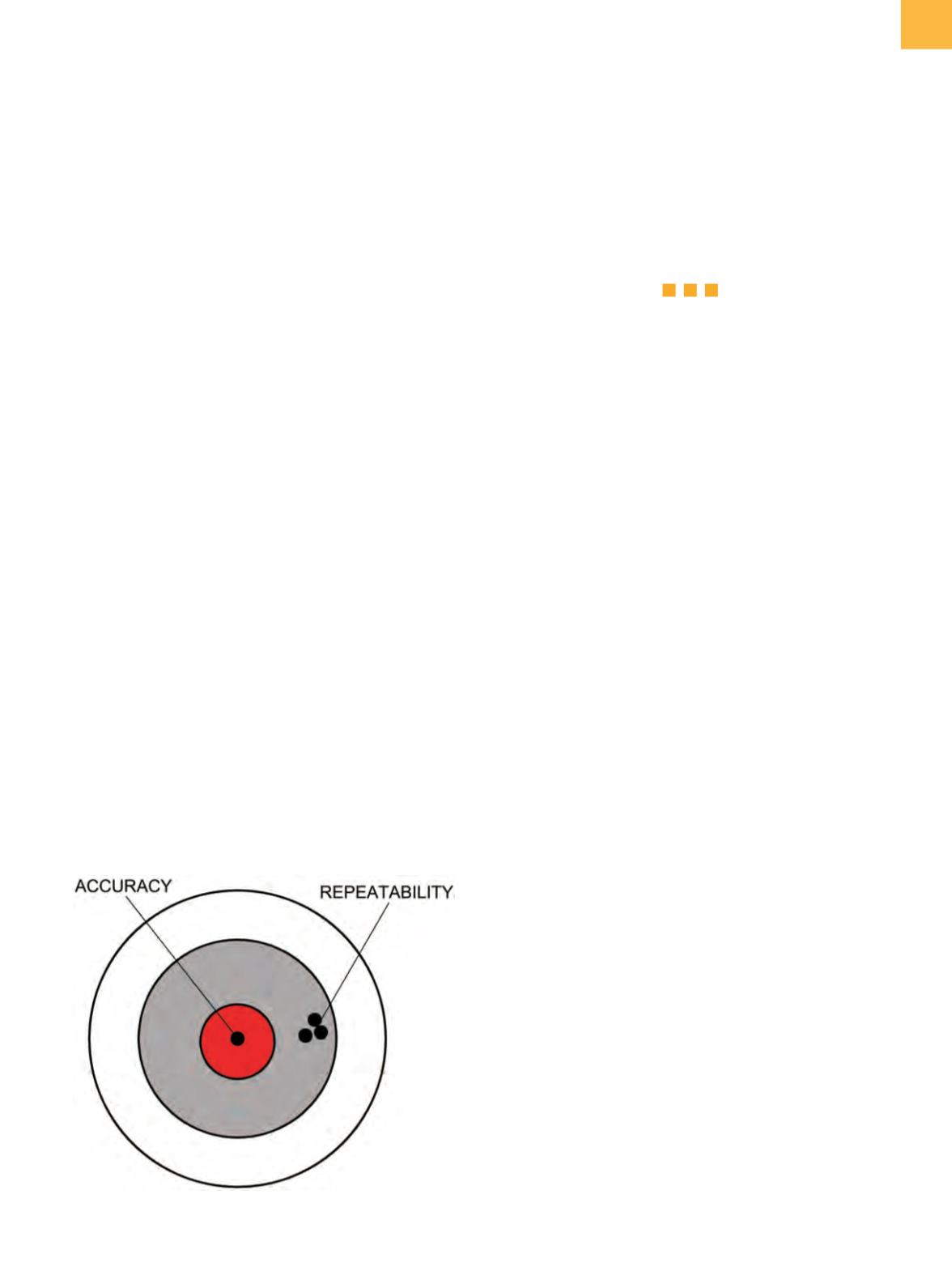

The easiest way to illustrate the difference between

accuracy and repeatability is to refer to the rifle target in

Fig. 2. A tight grouping is repeatability.

In addition to these terms, the geometric properties of

parallelismandorthogonality determine the performance

of a mechanical system.

Simple mechanical devices used for sample prepara-

tion, such as diamond saws, dimplers, and many others,

have easy-to-understandmechanical systems, andas long

as they are properly maintained and calibrated, they will

perform their designated tasks. With simpler machines,

if the quality of the results is lacking, then service and

adjustment are required.

A more complex machine is the flat lapper. There are

two basic types of lappers: open face, where the sample

being lapped is mounted to a fixture that is placed inside

or attached to a rotating ring, and lapperswith amast that

supports a sample holder and provides sample rotation

and movement across the lap surface. Either type can

use abrasive lapping films or a slurry feed system. Critical

parameters on a lapper include axial runout, lap flat-

ness, and the parallelism of the rotational, scan, and lap

spindle axes. The axial runout is the variation in height of

the lap surface at the edge as the lap rotates. For control-

lable results with any lapper, the lap should be flat and

not have axial runout. The parallelism of the rotational,

scan, and lap spindle axes determines the surface shape

of the sample. Axial runout will produce scalloping at the

sample edges. Lack of parallelism of the rotational axis

will produce a conical surface. Lack of parallelism of the

scanaxiswill produce a spherical surface. Aligningall three

axes is difficult to impossible, depending on themachine,

but it is necessary if die delayering is to be done. A 1 or

2 µm axial runout on the lap, or the rotational axis not

being parallel to the spindle, or the scan axis not being in

linewill produce a nonplanar result. The geometries of the

inaccuracies are easy to calculate. A 0.02 mrad misalign-

ment of the sample holder rotational axis will produce a

10 mm

2

sample with the corners more than 100 nm lower

than the center. When delayering, this conical shape can

make the results unacceptable. Accuracy depends on

set-up adjustments for the machine. Ongoing successful

sample preparationdepends onmaintaining these adjust-

ments. Periodic adjustments may need to be performed

by a specially trained technician or engineer.

THREE-AXIS-MOVEMENT MACHINES

There are machines available for die thinning or

delayering that have movement in three axes as well

as a rotating spindle that holds the tool. It is with these

machines that the concepts of accuracy, resolution, and

repeatability are most relevant. These machines move a

tool over the die surface by moving the sample in the

X

and

Y

axes and moving the tool in the

Z

axis.

In linear positioning systems, such as used on these

machines, the linear motion is commonly produced with

a lead screw, and the position is measured by a linear

encoder and scale. A computer controls themotor driving

the lead screw so that the encoder gives the desired posi-

tion value. The encoder has specifications for linearity and

resolution and, occasionally, zero reference repeatability.

In a numerically controlled machine, there is always a

reference or zero point that is periodically checked to

establish a positional reference. This is almost always at

the extreme travel of the machine in

X

or

Y

, while most

work is done near the center of the travel. The temperature

effects on the linear encoder scale then alter all positional

values by a function of the total travel from the zero point.

This means that the longer the travel, the greater the zero

shift produced by temperature changes. A machine with

200 mm of travel will have twice the thermal zero shift as

a machine with 100 mm of travel.

Fig. 2

Accuracy as opposed to repeatability

“IN LINEAR POSITIONING SYSTEMS,

SUCH AS USED ON THESE MACHINES,

THE LINEAR MOTION IS COMMONLY

PRODUCED WITH A LEAD SCREW, AND

THE POSITION IS MEASURED BY A LINEAR

ENCODER AND SCALE. ”