A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 6

2 7

enables the industrial R&D group and its

members to share the risks and rewards

of aluminum component development

and testing. “The major advantages of

putting ALTec in place is that it enables

a project-based approach that directly

responds to industry needs, combined

with an emphasis on clear communica-

tion with members to rapidly integrate

the advances in their product lines,”

says Gagnon.

For an affordable cost, members

participate in projects designed to

respond to specific challenges. Project

outputs are communicated via confi-

dential webinars and technical briefs,

and members are able to implement

the new technologies. Established in

2015 with seven members and two

sponsors, the group now has 18 mem-

bers including companies such as Ford

Motor Co., PPG Industries, Centerline,

and others with whom projects are

designed. Eight major partners includ-

ing Rio Tinto, Prima, the Aluminum

Association of Canada, and others pro-

vide additional funding and input into

the consortium’s overall direction and

goals. In total, ALTec represents nearly

$3.5 million dollars in R&D investment

per year.

PROJECT COVERAGE AREAS

Approximately 10 projects have

been initiated based on the needs

expressed by members. From a tech-

nical standpoint, the projects fall

under three areas, each led by an NRC

expert. These include manufacturing

of advanced aluminum components,

assembly of aluminum and multi-ma-

terial components, and durability and

performance evaluation and solutions.

“Increasing the productivity of

forming processes such as extrusion,

stamping, and die casting is our objec-

tive,” says ALTec manufacturing expert

Jean Savoie. “We’re helping members

develop new alloys and processes

suitable for rapid production of struc-

tural parts by hot stamping, assisting

them in extruding profiles with various

thicknesses, and developing new core

technologies for high integrity casting,

as well as intelligent dies for forming.

The last 10 years have seen a growing

emphasis on rapid, flexible processes

that will reduce the weight and cost of

components while accelerating their

path to market. We think this can be

achieved through better modeling and

simulation of forming processes, and

we measure our success by the quality

of the first prototypes that come out of

these optimized processes.”

On the assembly side, mechanical

fastening of aluminum to high strength

or stainless steel is being displaced by

friction stir welding (FSW), adhesive

bonding, and resistance spot welding.

Research is focused on finding the best

approach from a corrosion standpoint.

FSW is extremely promising, especially

if it can be made linear—the main chal-

lenge is large loads that result in high

robot payloads in an industry seeking

to minimize these payloads.

To address this issue, a novel

C-frame type robot is being designed

to minimize lateral loads and increase

forging loads. Looking ahead, it is clear

that engineers wonder which welding

or joining technique is the most appro-

priate for a given application, a ques-

tion that is becoming more difficult

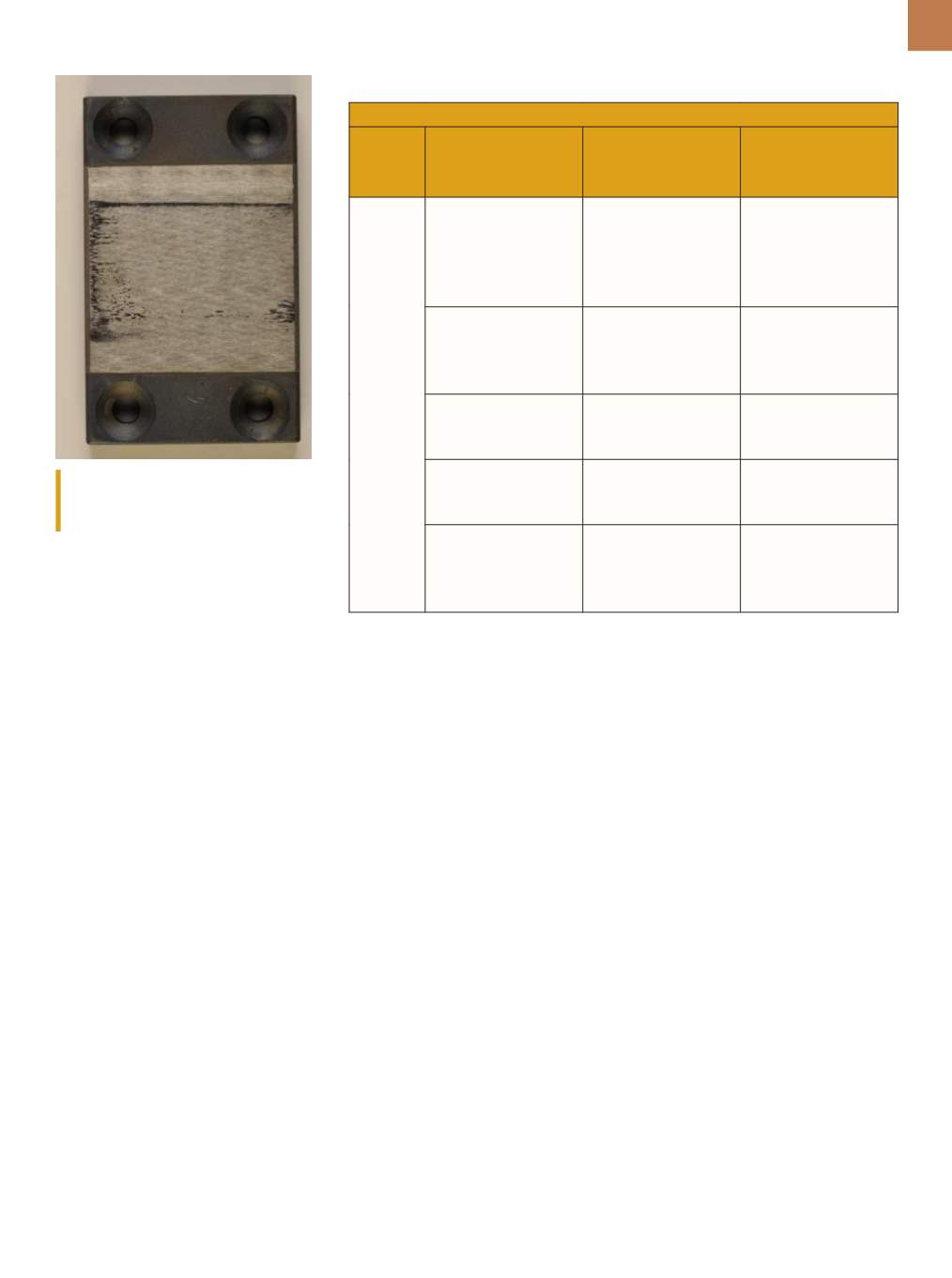

TABLE 1

—

PROJECT COVERAGE FOCUS

Project Coverage Areas

Manufacturing of

advanced aluminum

components

Assembly of

aluminum and

multi-material

components

Durability and

performance

evaluation and

solutions

Key

topics

covered

Warm and hot

forming of aluminum

sheet alloys at high

production rates

Durable structural

adhesive joints of

minimally pretreated

multi-material

structures

In-service stress

corrosion cracking:

Evaluation of high

strength aluminum

alloys

Heating coatings

for multifunctional

intelligent molds

Al/steel friction stir

welding process

optimization and

robotic solutions

Mitigating galvanic

corrosion of aluminum

in dissimilar material

assemblies

Tribological coatings

for multifunctional

intelligent molds

Weldability of Al alloys

Design and

production of large

hollow extrusions

Vacuum-assisted high

pressure die casting

of hollow aluminum

structural nodes

High velocity oxygen fuel coated sample

for strip draw test used to evaluate tribo-

logical performance.