A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 6

3 1

CANFSA STRUCTURE

CANFSA is led by director Michael

Kaufman, a professor at CSM, and two

site directors, Peter Collins and Amy

Clarke, associate professors at ISU and

CSM, respectively. The directors and

center are supported by the NSF-ap-

pointed center evaluator, David Meyer.

CANFSA’s target members include

organizations that research, produce,

process, or use non-ferrous structural

alloys. It is a member-driven organi-

zation, with participants consisting of

large corporations, small businesses,

government laboratories, and one

trade association. At present, CANFSA

has the following 14 members: Air Force

Research Laboratory, Army Research

Laboratory, Allegheny Technologies

Inc. (ATI), Boeing, Embraer SA, GE Avi-

ation, Honeywell International Inc., Los

Alamos National Laboratory, National

Aeronautics and Space Administration

(NASA), North American Die Casting

Association, Queen City Forging Co.,

Thermo-Calc Software Inc., Triumph

Group Inc., and Weber Metals Inc. Each

member has a seat on the industrial

advisory board (IAB), which provides

guidance to student projects and over-

sight of the overall research agenda.

Two levels of membership are available

within CANFSA—full or associate—with

the latter available to organizations

with less than 500 employees.

The managing director, Steve Mid-

son (research professor, CSM), focuses

on event planning, communications,

procurement of external research

grants, marketing, recruitment of new

members, and reporting and other

administrative functions.

CURRENT PROJECTS

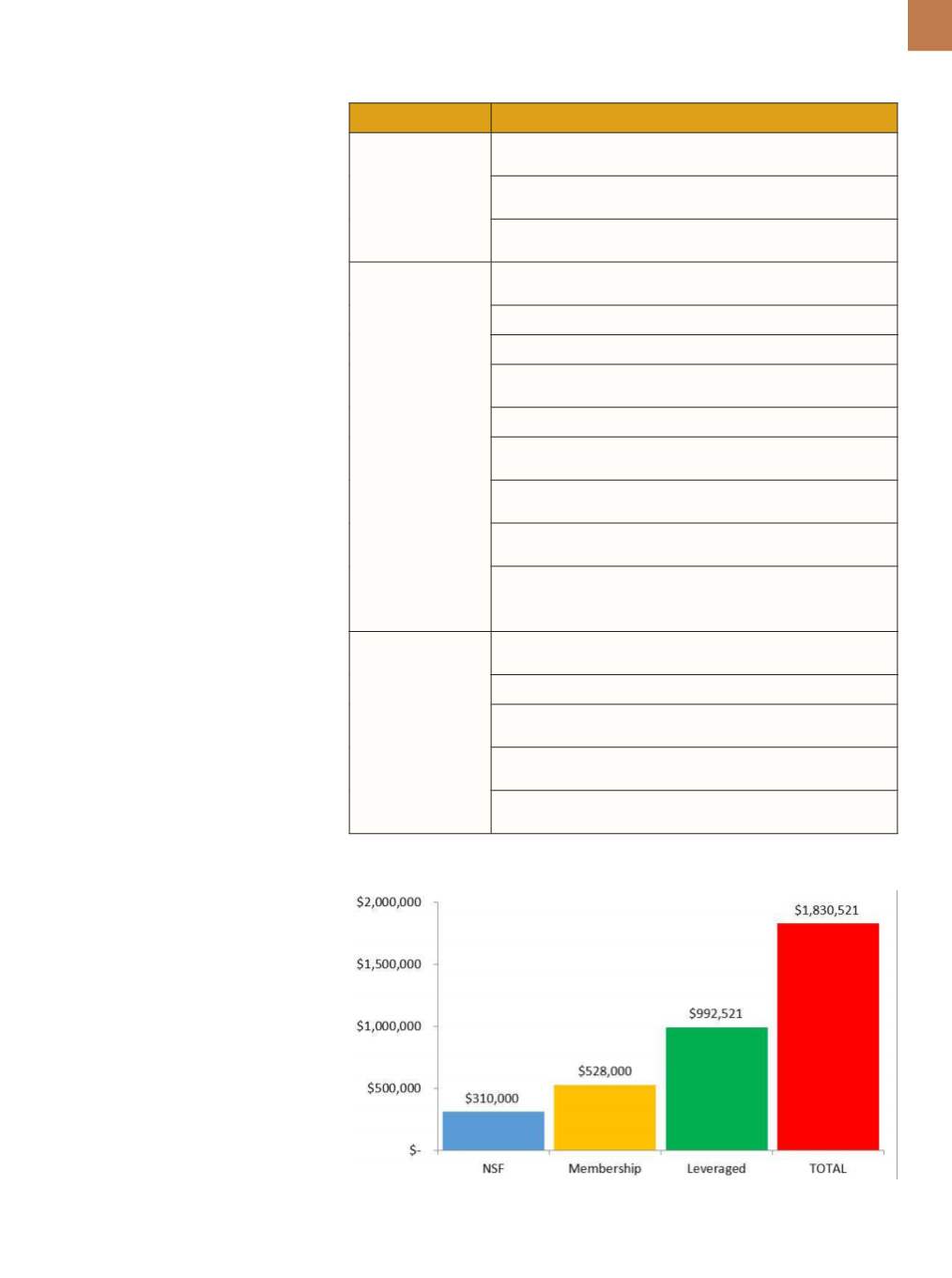

As shown in Fig. 1, current annual

funding for CANFSA is more than

$1.8 million, which originates from

three sources including membership

dues, National Science Foundation

funds, and external, leveraged projects

funded outside of CANFSA.

There are 17 ongoing research

projects within CANFSA, which are

divided into three thrust areas—light-

TABLE 1

—

ONGOING CANFSA PROJECTS

Focus area

Project title

Lightweight non-

ferrous alloys

Effects of Strain Variations on Aging Response & Corrosion

Properties of 3rd Generation Al-Li Alloys

High Temperature Stability and Mechanical Properties of

Micro-eutectics in Bulk Solidified Al-Fe-Si-V and Related Alloys

Damage Tolerance/Accumulation in Ultra Fine Grained

Magnesium Alloys

High performance

non-ferrous alloys

Engineering Fine Scale

α

-Precipitation for

High Strength

β

-Ti Alloys

Low-Level Hydrogen Effects on Toughness in Titanium Alloys

Measurement and Modeling of Anisotropy in Ti-6Al-4V Forgings

Mechanism of Dwell Fatigue Crack Initiation in Ti-7Al Under

Biaxial Tension-Tension Loads

High Temperature Titanium Alloys

Effect of Grain Size and Precipitate Volume Fraction

on Creep and Fatigue in Nickel Alloys

Characterization of Microstructure Evolution in Nickel-

Titanium-Hafnium Intermetallics for Bearing Applications

Understanding Strengthening of an Aerospace

Niobium-Hafnium-Titanium Alloy

Atomic Ordering in Alloy 690 and its Effect

on Long-Term Structural Stability and Stress

Corrosion Cracking Susceptibility

Advanced alloys

and processes

Collaboration to Accelerate the Discovery of

New Alloys for Additive Manufacturing

PVD Coatings Applied to Die Steel for Lube-Free Die Casting

Multilayer PVD Coatings for Service Life Extension of

Components Used in Aerospace and Manufacturing

Effects of Thermal Processing Variations on Microstructure

and High Cycle Fatigue of Beta-STOA Ti-6Al-4V

Understanding the Physical Metallurgy of a New Nickel-Based

Alloy with a Low Coefficient of Thermal Expansion

Fig. 1 —

CANFSA annual funding effective April 1, 2016.