A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 6

2 1

structure formation by pointing out the

importance of time over melt tempera-

ture during processing, emphasizing

the importance of melting kinetics

[7]

.

The use of high-purity aluminum and

a binary Al-Si eutectic alloy show that

the possibility of forming thixotropic

structures in materials with no practical

freezing range is at odds with the con-

ventional requirement of the freezing

range by inspecting the liquid fraction

versus temperature curve defined as

the processing window. Results suggest

that time sensitivity depends on alloy

mass, heat flux, and phase transforma-

tion temperature.

CONVENTIONAL CASTING

ANDALLOY DEVELOPMENT

Substantial advantages are ex-

pected using liquid metal engineering

on casting alloys with temperatures

exceeding the liquidus. However,

progress over the past few decades in

casting hardware and auxiliaries (par-

ticularly high-pressure die casting) was

not accompanied by understanding

and exploring opportunities created

by engineering liquid metal. Therefore,

there is renewed interest in the pro-

cessing side of die casting, especially in

controlling the nature of molten metal

supplied to the shot sleeve of the ma-

chine. Recently, high integrity castings,

where net shape parts have negligible

porosity after solidification became of

interest. Better quality components

with higher strength lead to potential

savings due to component size reduc-

tion for a given application, resulting

in lower material and energy consump-

tion and a smaller machine to manufac-

ture it, which translates to lower capital

investment.

Recent alloy development shows

that alloying aluminum with elements

having high melting points (e.g., V, Zr,

Cr, Ti or Mo) generates extremely coarse

compounds that degrade alloy prop-

erties in the as-cast state, and require

long, costly post-casting homogeniza-

tion. In some cases, even a long heat

treatment is not effective. Moreover,

to homogenize the molten alloy, high

overheating and long holding times

are required, leading to losses of more

volatile constituents. Therefore, it is

believed that intensive mechanical

shearing/de-agglomeration not only

homogenizes the chemical compo-

sition, but also refines alloying com-

pounds of complex chemistry that

control alloy properties during service.

The melt treatment during alloy gen-

eration should offer benefits including

reducing the overheating temperature

required during melting, reducing

the required holding time in the mol-

ten state, and reducing holding times

during post-cast heat treatment. In

some cases, heat treatment is elimi-

nated, thus improving the energy effi-

ciency of the entire process.

BENEFITS OF CONTROLLED

NUCLEATION

During solidification, the homoge-

neous nucleation, occurring randomly

in the bulk of the liquid, is always kineti-

cally less favorable than heterogeneous

nucleation, taking place on preferential

nucleation sites. The heterogeneous

nucleation can be further enhanced

by providing substrates for easy nucle-

ation described as nucleation potency.

The latter term is defined as the crystal-

lographic lattice mismatching between

materials of the substrate and nuclei.

An epitaxial nucleation model assumes

that heterogeneous formation of the

solid phase on a potent (small lattice

misfit) substrate occurs by epitaxial

growth of the transient solid phase

on the substrate surface under criti-

cal undercooling. This mechanism is

being explored to improve alloy prop-

erties through grain refinement. After a

nucleus is formed, solidification enters

the stage of growth. For decades,

there has been a discussion to deter-

mine which of two stages, nucleation

or growth, exerts a larger effect on the

casting structure. There is a merit in

the recent tendency towards emphasiz-

ing the paramount role of nucleation.

However, to take full advantage of

solidification, both stages, nucleation

and growth, should be understood and

explored.

Metallic oxides present in molten

alloys have a particular role in grain

refinement. During melting, pouring,

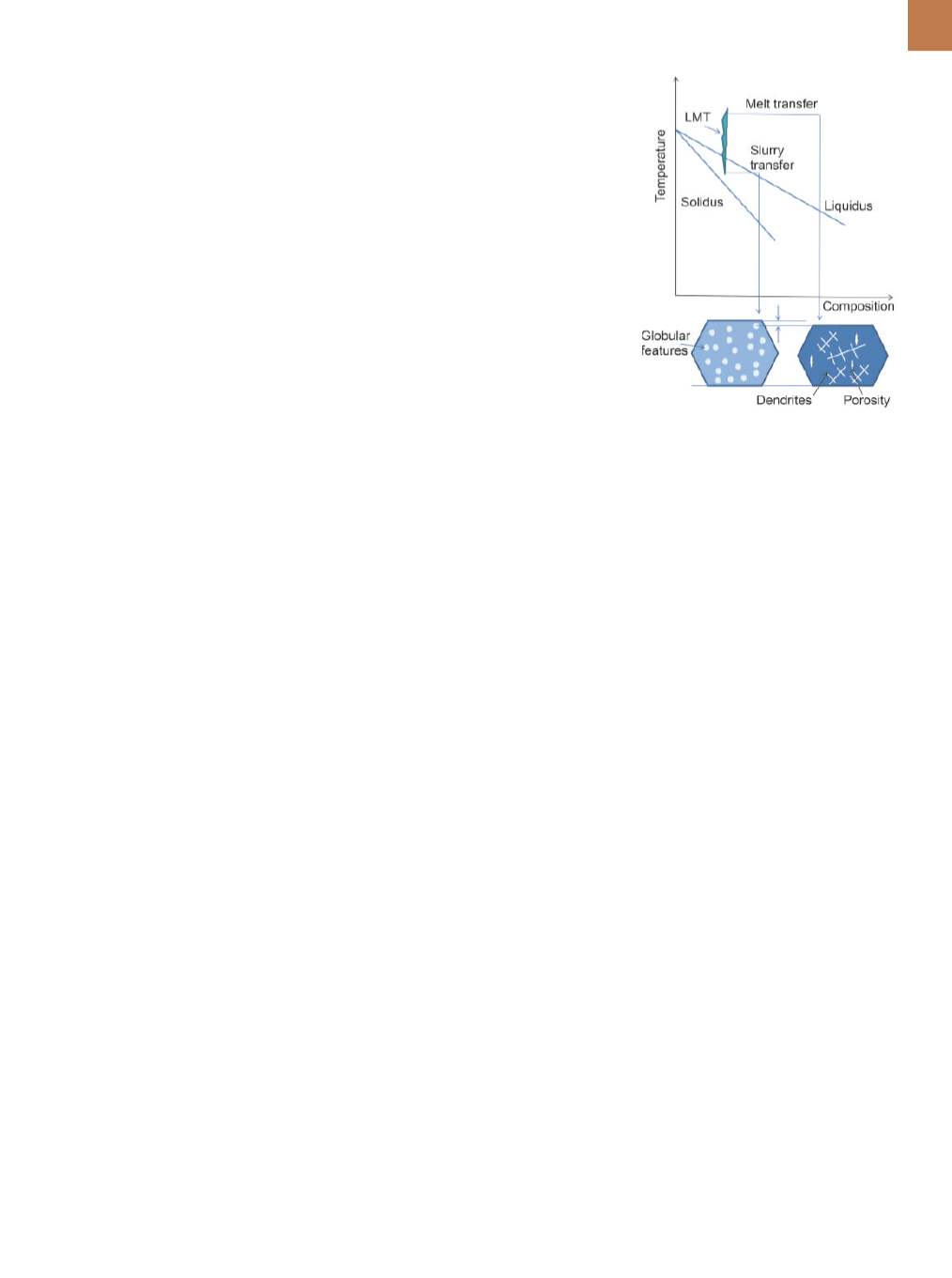

Fig. 5 —

Schematic emphasizes component

integrity and alloy microstructure; (left)

semisolid forming with globular morphol-

ogy, high integrity, and better net shape

dimensions; (right) forming from overheated

melt with dendritic morphology, porosity,

and larger shrinkage.

and transfer processes, oxide formed

on the free surface is entrained into the

alloy volume due to melt turbulence.

When an oxidized surface is folded

over onto itself and entrained into the

bulk liquid, a double oxide-film defect

is formed with characteristic features

of unbonded oxide surfaces separated

by a gas. Entrained oxides and other

defects preclude the production of high

integrity parts.

Liquid metal engineering not only

eliminates the harmful effect of oxide

inclusions, but also serves as an effec-

tive grain refiner. For example, delib-

erately dispersed oxide film on molten

Mg alloys using intensive melt shear-

ing functions as endogenous particles

for effective grain refinement. For the

Mg-9Al-1Zn alloy, microscopic analysis

of oxide extracted from molten alloy

reveals submicron-sized MgO particles

resulting from forced breakup of the

oxide films. High-resolution microscopy

reveals good lattice matching between

MgO and the

α

Mg matrix

[8]

. It is con-

cluded from this work that intensive

melt shearing disperses oxide films and

oxide particles at a level that results

in a slow rate of agglomeration, which

enables casting and solidification to

proceed with the grain refining effect.