A D V A N C E D M A T E R I A L S & P R O C E S S E S | O C T O B E R 2 0 1 6

2 0

net shape components with properties

substantially better than those in cast-

ings. The primary objective of engineer-

ing liquid metal within all semisolid

technologies is to generate thixotropic

structures through nucleation of glob-

ular forms instead of dendritic ones

during solidification. The former

improves flow during net shape form-

ing and provides other benefits

[4]

. In

contrast to dendritic forms, thixotropic

mixtures serve as deformable semi-co-

hesive spheroidal solids saturated with

liquid, where an applied macroscopic

stress is supported by both solid and

liquid phases. This deformation behav-

ior is unique for thixotropic structures.

Alloys with dendritic features cannot be

deformed by grain rearrangement due

to significant geometric interference of

complex solid features, leading to high

flow resistance.

The initial approach of semisolid

processing focused on rheocasting,

where the molten alloy treatment

during cooling to the liquidus-solidus

range caused transformation from den-

dritic to globular morphologies. Several

liquid metal treatments were intro-

duced as the technology progressed.

Semisolid processing was later dom-

inated by thixoforming (thixocasting,

thixoforging), where thixotropic raw

material produced during the first stage

was subsequently reheated to the semi-

solid range and subjected to net shape

forming. However, thixocasting soon

lost its advantage due to excessive cost,

and today’s semisolid processing is

again dominated by rheo routes.

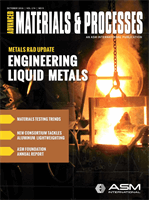

Fig. 3 —

Concept of liquidmetal treatments

during rheoforming, thixoforming, and liquid

base forming. LMT: Liquidmetal treatment

before transferring into die/mold for net

shape forming.

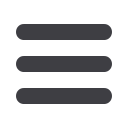

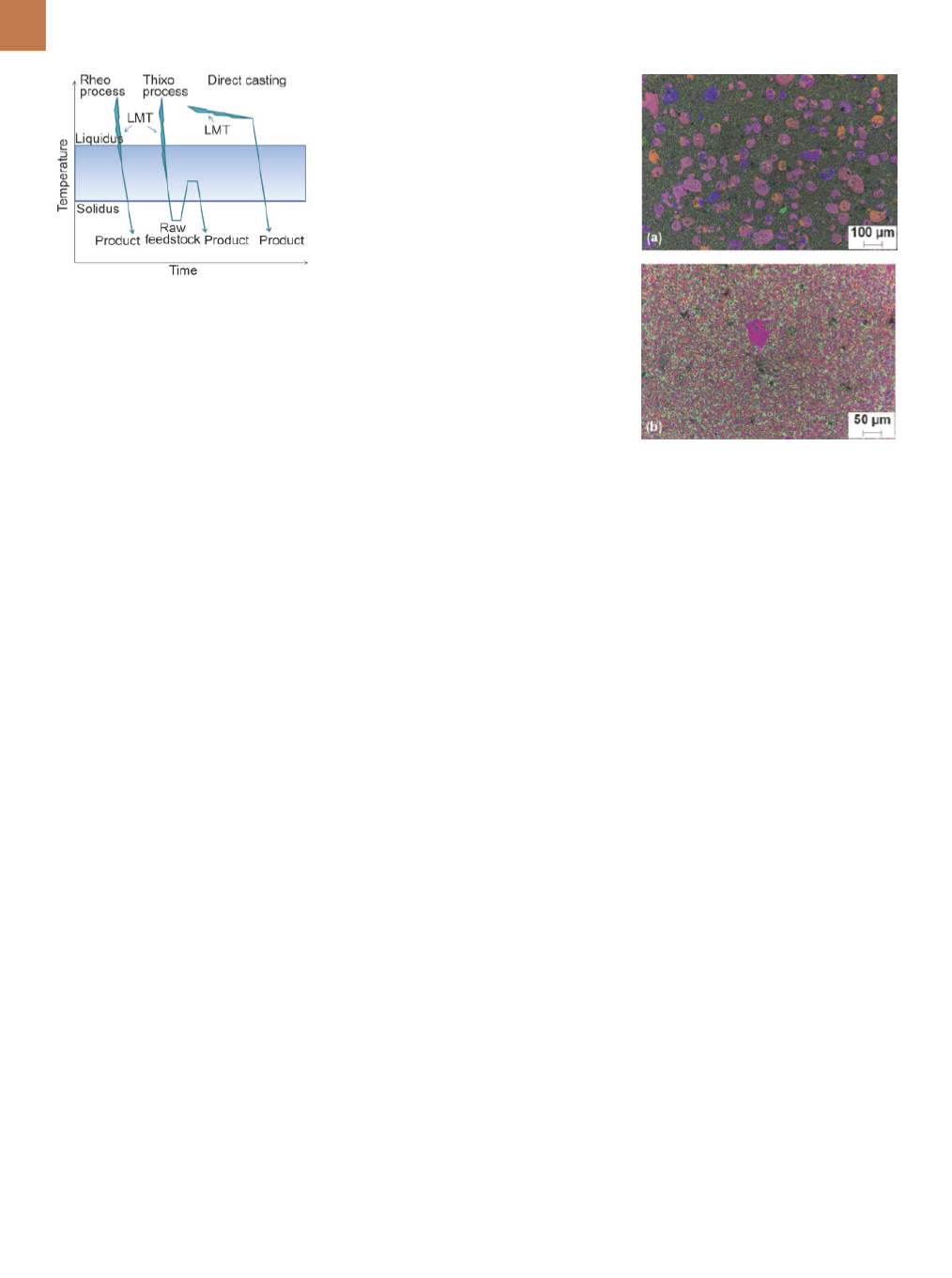

Fig. 4 —

Features of microstructure obtained

after liquidmetal treatment: (a) semisolid

processing with globular morphology of

primary solid; (b) near liquidus processing;

fine microstructure with a single globule of

primary solid seen in the center. Material:

Mg-9%Al-1%Zn magnesium alloy. Color

etching reveals approximate grain

orientations.

Treatment starts within a sin-

gle-phase liquid and continues during

coexistence of a two-phase thixo-

tropic slurry (Fig. 3). As a result, only

a portion of metal remains liquid and

requires attention at the time of net

shape forming. The solid fraction range

that enables processing was defined

between 5% and 60%. The upper limit

is considered the content above which

the alloy freezes, so it cannot flow into

the mold cavity. However, with the

invention of semisolid extrusion mold-

ing, the upper limit was substantially

raised to over 85%, meaning that only a

small fraction of liquid metal remained

at the time of net shape forming

[5]

.

The thixoforming path involves

partial remelting of the previously

solidified thixotropic alloy, creating

a fraction of fresh liquid within the

solid, which adds complexity. The

chemical composition of the liquid

fraction in the semisolid state dif-

fers from that measured for the bulk

alloy, and the differences grow with

decreasing temperature (Fig. 4a). The

overall alloy chemistry should be spe-

cifically designed for this purpose to

take advantage of having melts with

two different compositions, i.e., an

initial one and another at the forming

stage. The lack of specifically designed

alloys is one obstacle limiting commer-

cialization of semisolid processing.

NEAR-LIQUIDUS PROCESSING

Temperature and time are essen-

tial parameters of liquid metal engi-

neering. Initially, globular structure

formation was explained as the need

to break up dendrites during the freez-

ing process either using mechanical

stirring or other forms of agitation.

The fragments of dendrites within the

melt volume serve as nuclei of new

grains that transform into spheroids.

However, experimental evidence made

this mechanism questionable. Direct

observations of the solidification of

transparent liquids withmetal-like crys-

tallization characteristics and numer-

ical modeling suggest that globular

crystals form through direct nucleation

from a liquid instead of from fragments

of broken dendrites.

In general, the morphology of a

solid in a two-phase mixture of solid

and liquid is controlled by cooling or

convection, or a combination of both.

However, the particular role in gener-

ating globular forms is associated with

melt temperature

[6]

. Generally, lowering

the casting pouring temperature pro-

motes formation of equiaxed solidifica-

tion morphologies. In particular, when

superheating is sufficiently low, the

entire melt is undercooled and copi-

ous heterogeneous nucleation occurs

throughout. This leads to complete

elimination of the columnar zone in the

casting and to formation of fine equi-

axed grains in the entire volume. Exe-

cuting temperature control imposed by

the near liquidus concept is challenging

for certain hardware and larger alloy

volumes. A combination of melt shear-

ing and precise temperature control

in the near liquidus range conducted

within the processing machinery leads

to an ultrafine structure of magnesium

alloys and a superior combination of

strength and ductility (Fig. 4b).

Experiments show the need for

a better understanding of thixotropic