A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

O C T O B E R

2 0 1 6

1 9

alloys with specific temperatures and

chemistries to generate thixotropic

morphologies is also being explored. A

generation of unique alloys and com-

posites made by mixing thixotropic

slurries instead of molten alloys offers

another opportunity

[2]

.

Characteristics of two-phase slur-

ries are affected by the deformation his-

toryof thematerial in the solidstateprior

to melting as it occurs during a stress-in-

duced melt activation (SIMA) process,

which demonstrates process complex-

ity. The liquid alloy treatment can occur

either at the stage of raw material gen-

eration for further processing, as in

semisolid technologies, or directly prior

to casting into net shape components.

The overall objective at the stage of raw

material generation might be limited to

alloy microstructure. However, during

forming of net shape components, it

must cover both alloy microstructure

and component integrity. The oppo-

site approach of manipulating liquid to

generate foamed materials instead of

high-integrity structures is also of engi-

neering and commercial interest

[3]

.

Liquid metal engineering is appli-

cable to all alloys although current

research is focused on aluminum and

magnesium due to their lower melting

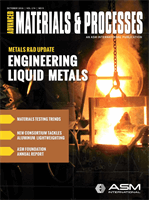

Fig. 1 —

Clamp area of 1200-ton, high-pressure die casting machine used for industrial-size

trials at CanmetMaterials facility.

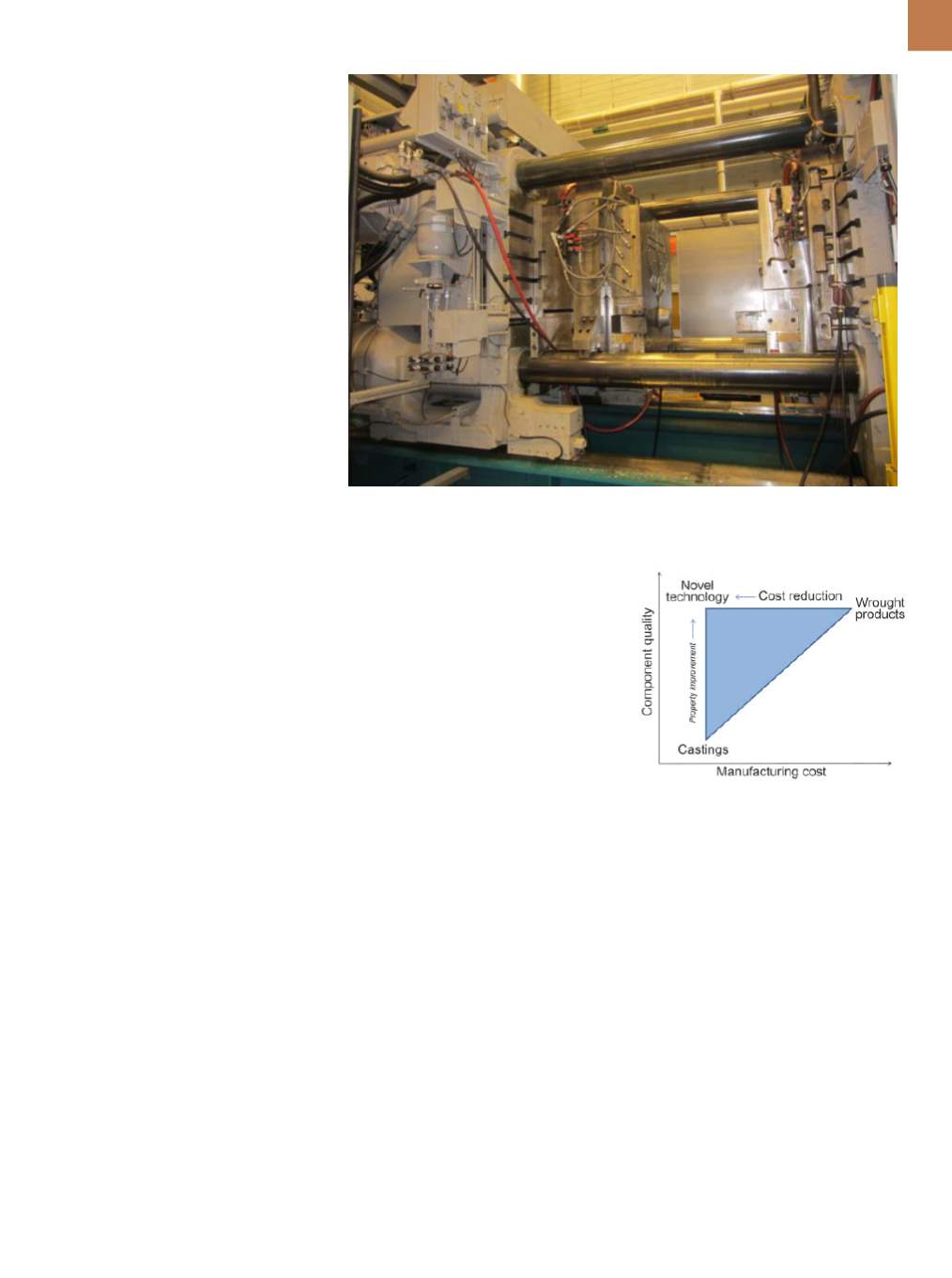

Fig. 2 —

Cost-quality relationships for

components manufactured through

casting and through solid state wrought

path. Anticipated location of the novel

technology indicated for comparison.

temperatures, and, therefore, less chal-

lenging designs of processing hardware.

Note that the term liquid metal engi-

neering has also been used for decades

by the U.S. Atomic Energy Commission

for development and non-nuclear test-

ing of liquid-metal reactor components,

covering totally different processes and

materials from those described here.

SEMISOLID STATE

TECHNOLOGIES

Invented in the early 1970s, semi-

solid processing was initially seen as a

technology capable of manufacturing

M

any factors must be considered

when selecting a manufactur-

ing technique to fabricate com-

mercial components for large-scale

production, such as in the automotive

industry (Fig. 1). Two issues of utmost

importance are part quality and cost.

During part design, many manufactur-

ing choices are available. The majority

are associated with either net shape

forming directly from the liquid state

or those involving complex multistep

operations involving a wrought path

with additional hot and cold forming,

machining, and other shaping pro-

cesses following casting. Conventional

casting offers limited part quality at

relatively low cost. By comparison,

solid state forming generally provides

better properties at substantially

higher cost. Work is being done to

improve casting quality and to reduce

solid state processing cost. However,

novel technology that combines the

best features of both processes might

offer the ultimate solution—the high-

est properties achievable in wrought

products at the low cost and simplicity

of casting (Fig. 2).

LIQUID METAL ENGINEERING

Liquid metal engineering is gain-

ing attention as a new technology for

large-scale production. The technique

involves a variety of physical and

chemical treatments of molten metal

to influence solidification. A simpli-

fied approach limits the phenomenon

to single-phase molten alloys above

the liquidus line. However, it should

generally cover manipulating liquid

alloys coexisting with a solid phase, as

is the case at temperatures in the liq-

uidus-solidus region of the particular

phase diagram

[1]

. Current techniques

include melt filtering, rotary degas-

sing, and various stirring/shearing/

agitation methods using ultrasound,

electromagnetic, magneto-hydrody-

namic, and mechanical means (e.g.,

reciprocating injection screw and var-

ious types of mixers). For example,

ultrahigh shear mixing/de-agglomer-

ation solutions used in the food and

cosmetic industries are also being

tested with metals. Developing molten