A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

1 2

NEW MATERIAL NETS BETTER

NUCLEAR FUEL RECYCLING

An

international

collaboration

including researchers from the DOE’s

Pacific Northwest National Laboratory,

Richland, Wash., and Lawrence Berkeley

National Laboratory, Calif., is investigat-

ing whether metal organic frameworks

(MOFs) could improve nuclear fuel recy-

cling by capturing radioactive xenon and

krypton at ambient temperature, avoid-

ing the expensive, energy-intensive

cryogenics necessary in current practice.

MOFs contain tiny pores as small as a

single molecule. When gaseous mixtures

are passed through MOF walls, certain

gases adsorb to the material, while the

rest sift through.

To determine which MOFs out of

125,000 possibilities could be used for

xenon and krypton separation, com-

putational chemists used machine

learning techniques to evaluate the

materials based on seven predictive

characteristics. They identified SBMOF-1

with a pore size close to that of a xenon

atom as the best candidate. Laboratory

tests confirmed that SBMOF-1 trapped

xenon until the gas saturated the mate-

rial, and in the absence of xenon it cap-

tured krypton, indicating that a mixture

could be passed through SBMOF-1 twice

to capture both gases. In high humidity,

SBMOF-1 retained more than 85% the

amount of xenon as in dry conditions,

and after 10 cycles of vacuuming, it col-

lected just as much xenon as in the first

cycle, indicating a high degree of stabil-

ity for long-term use.

pnnl.gov, lbl.gov.

NOW YOU SEE IT,

NOW YOU DON’T

Researchers at the University of

Cambridge, UK, developed a type of

smart glass that switches from trans-

parent to opaque and back using mini-

mal energy. The glass is embedded with

Smectic A composites, which can be

changed from clear to cloudy millions

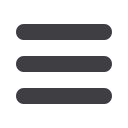

A molecular model of a newMOF that selectively traps xenon, a gas released

during reprocessing of nuclear fuel.

Smart glass goes from clear to opaque

and back again, millions of times.

BRIEF

A team of researchers from

Lawrence Livermore National Laboratory,

Calif., and

University of California, Santa Cruz

devised a method for dou-

bling the performance of 3D-printed graphene-base supercapacitors. The

technique involves sandwiching lithium ion and perchlorate ion between

layers of graphene in aerogel electrodes, substantially improving electrode

capacity while maintaining an excellent rate capability.

llnl.gov, ucsc.edu.

Cheng Zhu mixes ink material while colleagues observe. Courtesy of Julie Russell/LLNL.

of times and kept in either state for as

long as desired. The composites can be

produced in a roll-to-roll process and

printed onto plastic. The main com-

ponent of Smectic A, a smectic liquid

crystal, is comprised of molecules with

similar directional ordering arranged in

stacked layers, which confine themove-

ment of ionic additives.

Whenvoltage is applied,molecules

align themselves with the electric field,

rendering the glass transparent. When

voltage direction is changed, the ionic

additives disrupt the crystal layer struc-

ture, making the glass appear milky.

Increasing voltage frequency freezes

out ionic additive movement, reverting

the pane to transparent. These transi-

tions happen in a fraction of a second,

and when the voltage is cut, the mate-

rial remains in its current state until the

user changes it—so unless the material

is actively switching states, it requires

no power. “You could have smart win-

dows in an office building that auto-

matically become more or less opaque,

depending on the amount of sunlight

coming through,” explains Professor

Daping Chu. The smart glass could also

be used in automotive applications and

advertising.

www.cam.ac.uk.

EMERGING TECHNOLOGY