A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 6

1 1

realistic damage. While there were

some discrepancies between the size

and shape of cracks on the resulting EIT

maps and data from visual inspection

and thermograms, overall the approach

detected damage well before it was

visible with infrared thermography.

udel.edu.

Thomas Schumacher (left) and Erik

Thostenson are leading research on a

new technique to monitor the health of

structures such as roads and bridges.

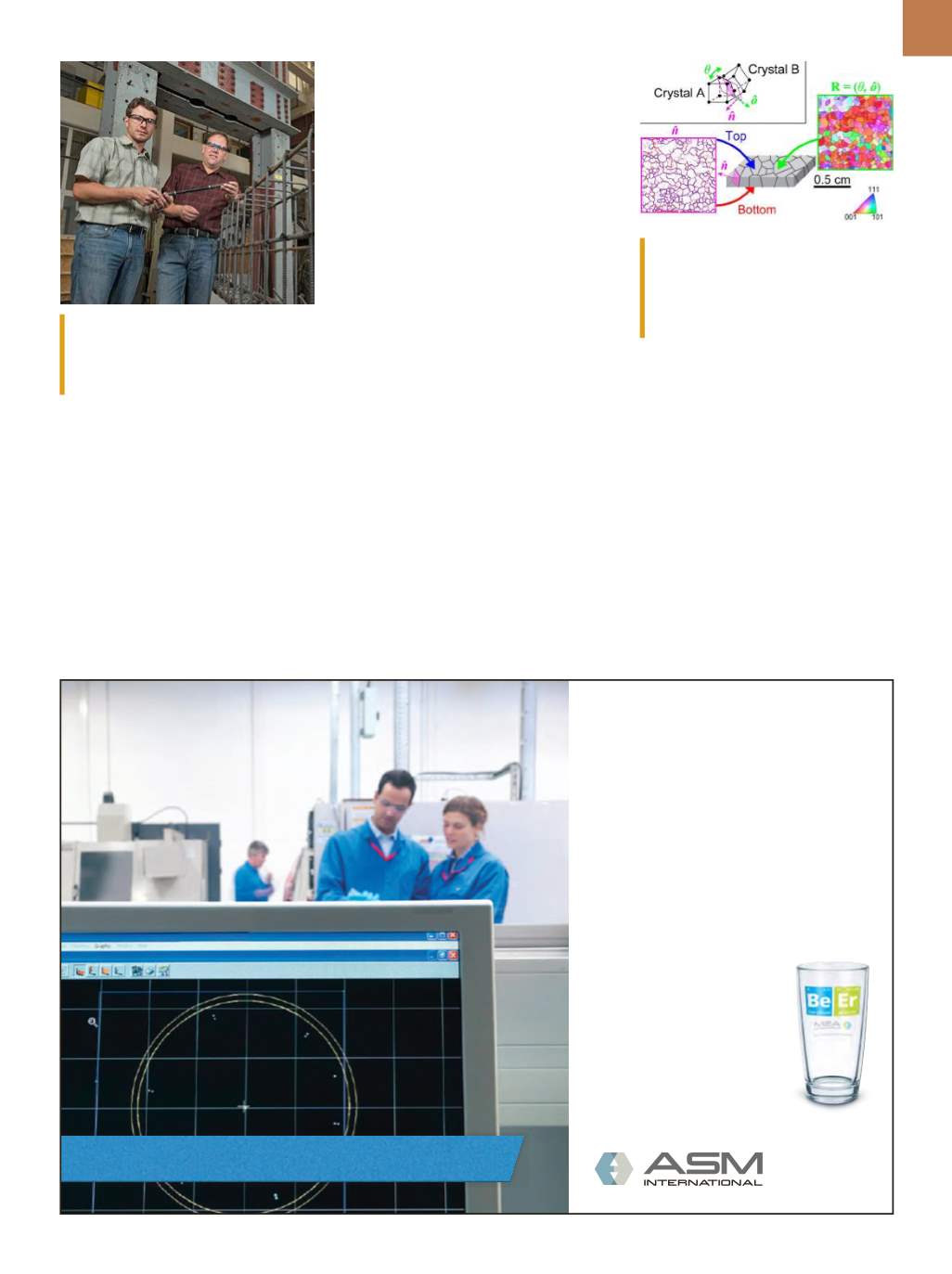

side. Using software, grain boundaries

were connected from one side to the

other, reconstructing their 3D orienta-

tion. This data was combined with elec-

tron microscope images to show the

orientation of individual crystal lattices

within each grain and how they relate

to those of adjacent grains. The new,

nondestructive method determines all

five necessary characteristics of grain

boundaries, whereas previous methods

achieved only two or three.

mit.edu.

A NEW LOOK AT

POLYCRYSTALLINE METALS

By combining established testing

technologies in a novel way, research-

ers from Massachusetts Institute of

Technology, Cambridge, and colleagues

devised a new approach to characterize

the microstructure of polycrystalline

metals. The method marries optical

and electron microscopy. It is also fast,

affordable, accurate, and accessible—a

combination not yet achieved with

current testing methods for these met-

als, which are comprised of a random

matrix of multiple small crystals rather

than a single, large crystal, making

them difficult to analyze.

Quantifying the characteristics

of interfaces between crystals in poly-

crystalline metals allows their material

properties to be determined. To do this,

researchers took optical microscope

images of both sides of a sheet of poly-

crystalline metal foil thin enough for

single grains to be seen from either

FREEPERIODICBEERGLASS! Get a FREE Periodic Beer Glass when you ask for your no-obligation training assessment. Contact Ravi Dodeja for complete details. Phone: 440.338.5414 Email: ravi.dodeja@asminternational.org CUSTOMIZEDTRAINING COMESTOYOU ASM’s Customized On-Site Training brings personalized courses to your facility that will elevate performance and increase production. Features include: • A productive use of your staff’s time with convenient access to world-class instructors at your facility • Information that is immediately applicable to • Programs customized to fit your needs your business after the course is completed REGISTER NOW AT ASMINTERNATIONAL.ORG/LEARNING/COSTA newmethod combines optical micros-

copy (left, pink) with electron backscatter

diffraction (right, green) to measure char-

acteristics of the boundaries between

crystal grains. Courtesy of Matteo Seita.