A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

8

METALS | POLYMERS | CERAMICS

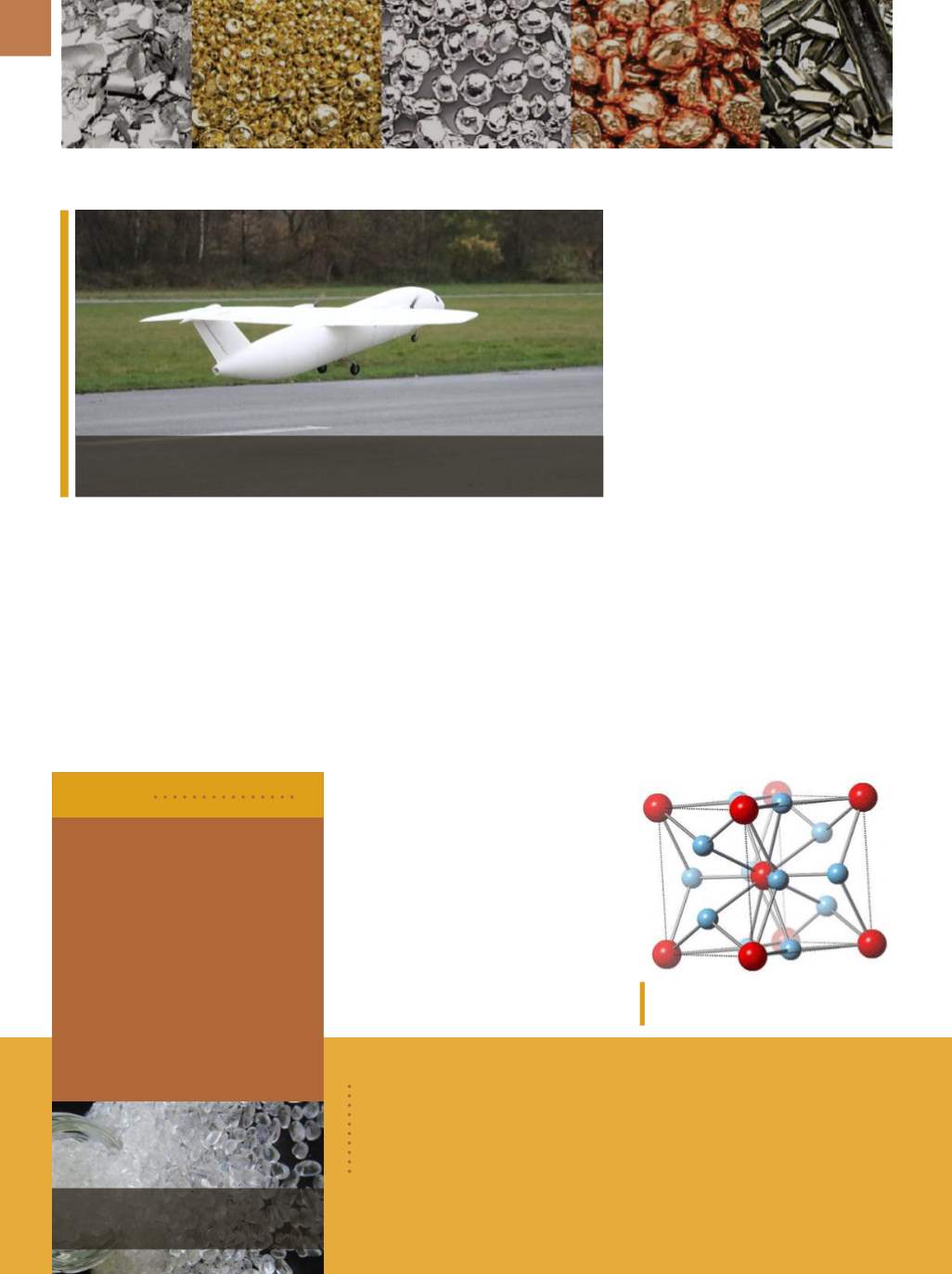

GOLD BOOSTS TITANIUM

KNEE STRENGTH

Titanium is the leading material for

artificial knee and hip joints because it is

strong, wear resistant, and nontoxic, but

adding gold might make implants even

better. “It is about three to four times

harder than most steels,” says Emilia

Morosan, a materials science professor

at Rice University, Houston. The proper-

ties of a 3-to-1 mixture of titanium and

gold with a specific atomic structure

impart the hardness. “It’s four times

harder than pure titanium, which is

what’s currently being used inmost den-

tal implants and replacement joints.” It’s

not clear that Morosan and former grad-

uate student Eteri Svanidzewere the first

to make a pure sample of the ultrahard

beta form of the compound. However,

due to a couple of lucky breaks, they

are the first to document the material’s

remarkable properties.

Researchers measured the hard-

ness of the beta form of the crystal and

also performed other comparisons with

Thor, a 3D-printed flying model, took off for its maiden flight in Germany last

November.

Polyscope Polymers B.V.,

the

Netherlands, expanded its Xiran

heat boost range. Originally

introduced to increase the high

temperature resistance of acry-

lonitrile butadiene styrene and

acrylonitrile styrene acrylate, Xiran

heat boosters can now increase the

heat performance of other styrenic

polymers, such as polystyrene and

styrene acrylonitrile, as well as

polymethylmethacrylate.

www.polyscope.eu.

BRIEFS

Stainless steel rebar produced by

Outokumpu,

Finland, is being used to

reinforce a spill basin at the new liquefied natural gas Gate Terminal on

Rotterdam’s North Sea coast. Both the basin’s concrete and reinforce-

ment must withstand the extreme conditions of a cryogenic environment

and temperatures as low as -165°C.

outokumpu.com/rebar.

PRINT ME AN AIRPLANE

Airbus, France, is using a mini

aircraft project known as Thor (test-

ing high-tech objectives in reality) as a

testbed for futuristic aircraft technolo-

gies—from 3D-printed structural parts

to advanced aerodynamics and even

artificial intelligence. The initial Thor

version weighs approximately 21 kg

and can fit in a 4×4 m square. It is pow-

ered by two 1.5-kW electrically-driven

propellers, and 90% of its structural

components were 3D-printed from

plastic polyamide powder.

“This mini aircraft does not repre-

sent an actual airliner design Airbus is

considering, rather it is a platform to

enable low-risk and fast-track devel-

opment of different technologies in

real flying conditions,” explains Detlev

Konigorski, who oversees the project.

“The first version was to test whether

the slogan ‘Print me an airplane’ can be

converted into reality.”

A major advantage of Thor is the

short lead time of 3D printing, which

significantly reduces development time

for producing the technology demon-

strator compared to traditional man-

ufacturing methods. Using an existing

design concept, it took seven weeks

to print the aircraft’s 60 structural

segments, followed by one week for

assembly and three days to fine tune

the electrical systems before it was

flight-ready.

airbus.com.

Crystal structure of beta titanium-3-gold.

Courtesy of E. Morosan/Rice University.

Xiran heat boosters resist high

temperatures.