A D V A N C E D

M A T E R I A L S

&

P R O C E S S E S |

S E P T E M B E R

2 0 1 6

7

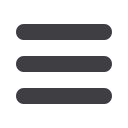

WOOD YOU LOOK AT THAT?

Liangbing Hu and his team at

the University of Maryland, College

Park, removed the molecule in wood—

lignin—that makes it rigid and dark in

color. They left behind the colorless

cellulose cell structures, filled them

with epoxy, and created a version of

the wood that is mostly see-through.

“It can be used in automobiles when

the wood is made both transparent and

high strength,” says Hu. “You could also

use it as a unique building material.”

Xylem and phloem pass water and

nutrients up and down the tree. These

vertically aligned channels in the wood

are a naturally grown structure that can

be used to pass light along, after the

wood has been treated. The resulting

3-in. block of wood features both high

transparency and high haze, the ability

to scatter light. This would be useful,

says Hu, in making devices comfortable

to look at. It would also help solar cells

trap light because the light could easily

enter through the transparent function,

but the high haze would keep it bounc-

ing around near where it would be

absorbed by the solar panel.

For more

information: Liangbing Hu, binghu@

umd.edu,

www.umd.edu.

Are you working with or have you

discovered a material or its properties

that exhibit OMG - Outrageous

Materials Goodness?

Send your submissions to

Julie Lucko at

julie.lucko@asminternational.org.

OMG!

OUTRAGEOUS MATERIALS GOODNESS

A block of wood is made transpar-

ent at the University of Maryland.

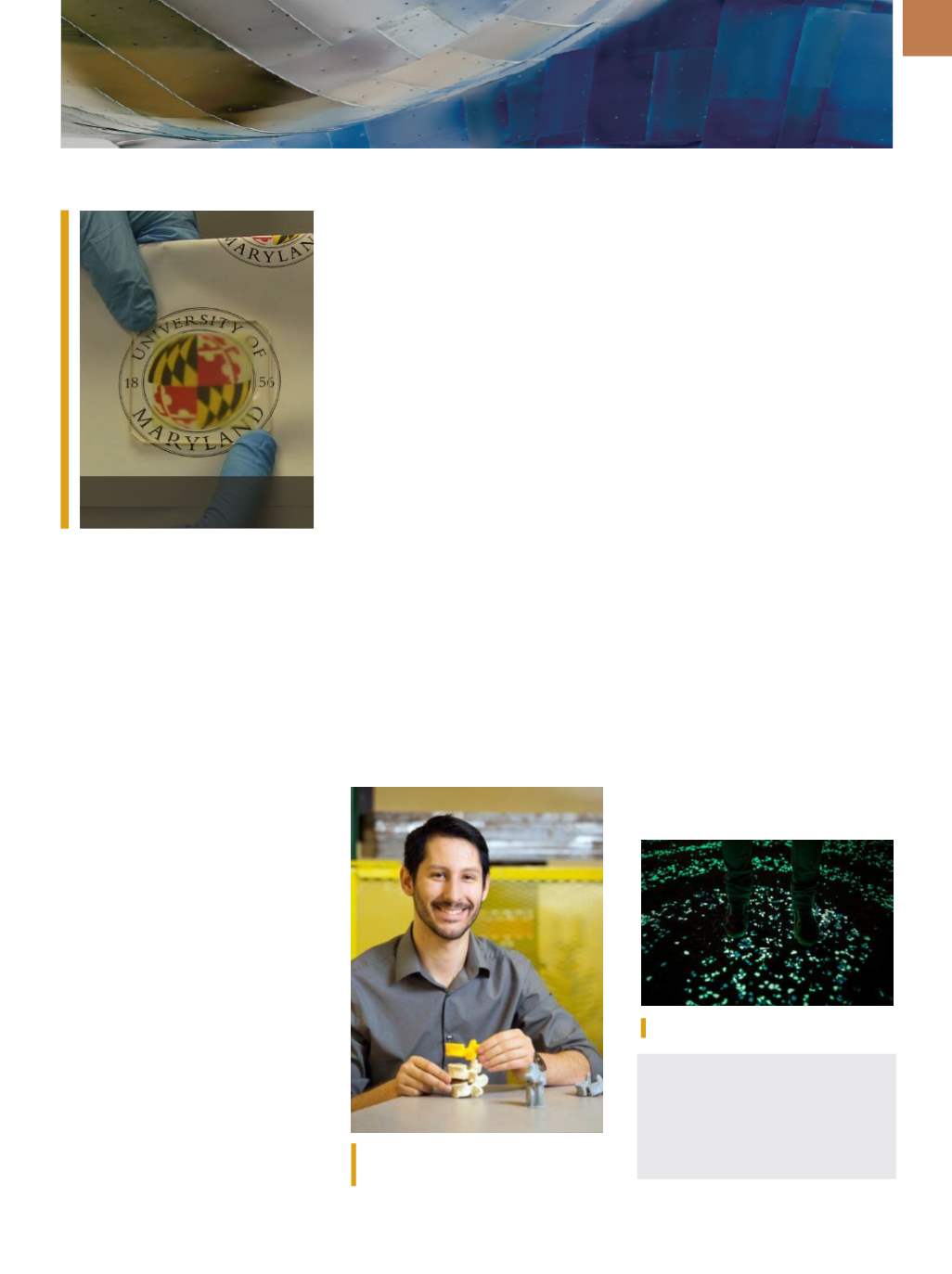

Glow-in-the-dark cement.

SimuBone could replace cadavers in

medical research.

3D-PRINTED BONES ADVANCE

MEDICAL RESEARCH

Advanced Bone Technology, Far-

go, N.D., is hoping to reduce cadaver

use in medical research by 3D printing

artificial bones. SimuBone is an arti-

ficial bone platform that can be man-

ufactured on demand at a fraction of

the cost of alternatives. It combines

engineered materials with a specialized

additive manufacturing process to pro-

duce what is said to be the most realis-

tic alternative to human bone available.

High-resolution manufacturing precise-

ly reproduces every detail of the desired

bone, including the contour of cortical

hard bone and the intricate structure

of trabecular spongy bone. SimuBone’s

performance against engineered ma-

terials and processes is comparable to

live bone and tailorable to a specific

sex, age, disorder, or even a particular

patient. By modifying the geometry

and performance to customer specifi-

cations, SimuBone devices reportedly

meet needs ranging from repeatable

lab tests to personalized healthcare.

The artificial bone will also enable test-

ing and development of medical devic-

es and training for surgical procedures.

advancedbonetech.com.

LIGHT-EMITTING CEMENT

SAVES ELECTRICITY

José Carlos Rubio at the Univer-

sity of San Nicolas Hidalgo-Michoac-

an, Mexico, created a cement additive

that absorbs solar energy during the

day and then emits light for up to 12

hours after dark. The glow-in-the-dark

cement—which would eliminate the

need for electricity to light highways—

is the latest innovation in concrete and

cement products. Rubio modified the

microstructure of the cement, allow-

ing the concrete to take in solar energy

and convert it into light. He says the

material could last as long as 100 years

and the intensity of blue or green light

can be adjusted depending on need.

Unlike plastic fluorescents, which have

an average lifespan of three years due

to decay from UV rays, Rubio explains

that his cement will not degrade as a

result of sunlight exposure. In addition,

the only byproduct of the manufactur-

ing process is steam.

www.umich.mx.