A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

6

MARKET SPOTLIGHT

FEEDBACK

POWDER METALLURGY INDUSTRY SEES STEADY GROWTH

According to analysis from the

Metal Powder Industries Federation,

Princeton, N.J., the powder metallurgy

(PM) industry will see modest growth

in 2016, following a healthy 2015. Con-

ventional press-and-sinter companies

and metal powder producers report

good business levels, as do companies

involved with metal injection molding,

metal additive manufacturing (MAM),

and hot isostatic pressing. However,

refractory metal demand has continued

to decline.

Developing metal powders for

MAM via gas atomization is a new

trend likely to be accelerated by most

leading powder makers, say analysts.

Meanwhile, successful use in the aero-

space and medical sectors continues

to pave the way for future applications.

Although the MAM market currently

remains small and limited to about

15 commercially available materials,

it offers exciting promise for PM in the

years ahead.

Another trend is the growing

need for precision machining of PM

parts. Powder suppliers are introduc-

ing high-performance lubricants and

additives for the press-and-sinter PM

The ASMMaterials Education Foundation supports

educators through a free materials science work-

shop called ASMMaterials Camp–Teachers. This

weeklong lab experience shows educators how to

use applied engineering techniques in their class-

rooms. Several 2016 camps have already taken

place withmore scheduled throughout the year.

Below are a few recent comments.

AWESOMESAUCE

I cannot overstate how awesome this

camp was on a multitude of levels. I could

have gone for a week and a half just so

we could get to and finish composites.

There was so much material and so

many ideas presented that it was almost

overwhelming. The instructors did a great

job of explaining the material and how to

present it to students.

Justin Orlando

REFRESHING WORKSHOP

The instructors were incredibly knowl-

edgeable and accommodating. They

went out of their way to help everyone

understand the material, feel comfort-

able enough to implement it, andmade

adjustments to fit my schedule. I conduct

professional workshops myself and am

pretty demanding about my expecta-

tions for professional development. As a

seasoned educator, I often find that other

programs lack appropriate materials or

presentation style. Not so with the ASM

workshop. Instead of my usual critical

attitude, I found this workshop to be a

refreshing example of how one should be

conducted—with pertinent lessons, excel-

lent instructors, and practical materials to

implement.

Kathleen Dwyer

We welcome all comments

and suggestions. Send letters to

frances.richards@asminternational.org.

market. Further, the aluminum pow-

der market for PM parts applications is

undergoing a new surge as automotive

designers seek lighter weight parts. The

use of higher-strength aluminum alloys

with metal matrix composites is experi-

encing renewed interest to reduce mass

and provide improved properties, and

this focus is currently a project within

the Lightweight Innovations for Tomor-

row consortium.

While MAM hype has moderated,

an estimated 50-100 companies and

organizations are actively developing

programs that use metal powders. To

this end, machine sales are surging, but

most MAM installations produce parts in

short runs of up to 100 units. The aero-

space andmedical industries are leading

adopters of this developing technology.

So far, the main MAM powder materials

include 316 and 17-4 PH stainless steel,

cobalt chrome, and titanium. Other

materials used in MAM include Inconel

625 and 718 alloys, platinum, molybde-

num, and tungsten. Most companies in

the PM industry view MAM as a comple-

mentary technology and an opportunity

to enter a new technology sector.

For more information, visit mpif.org.

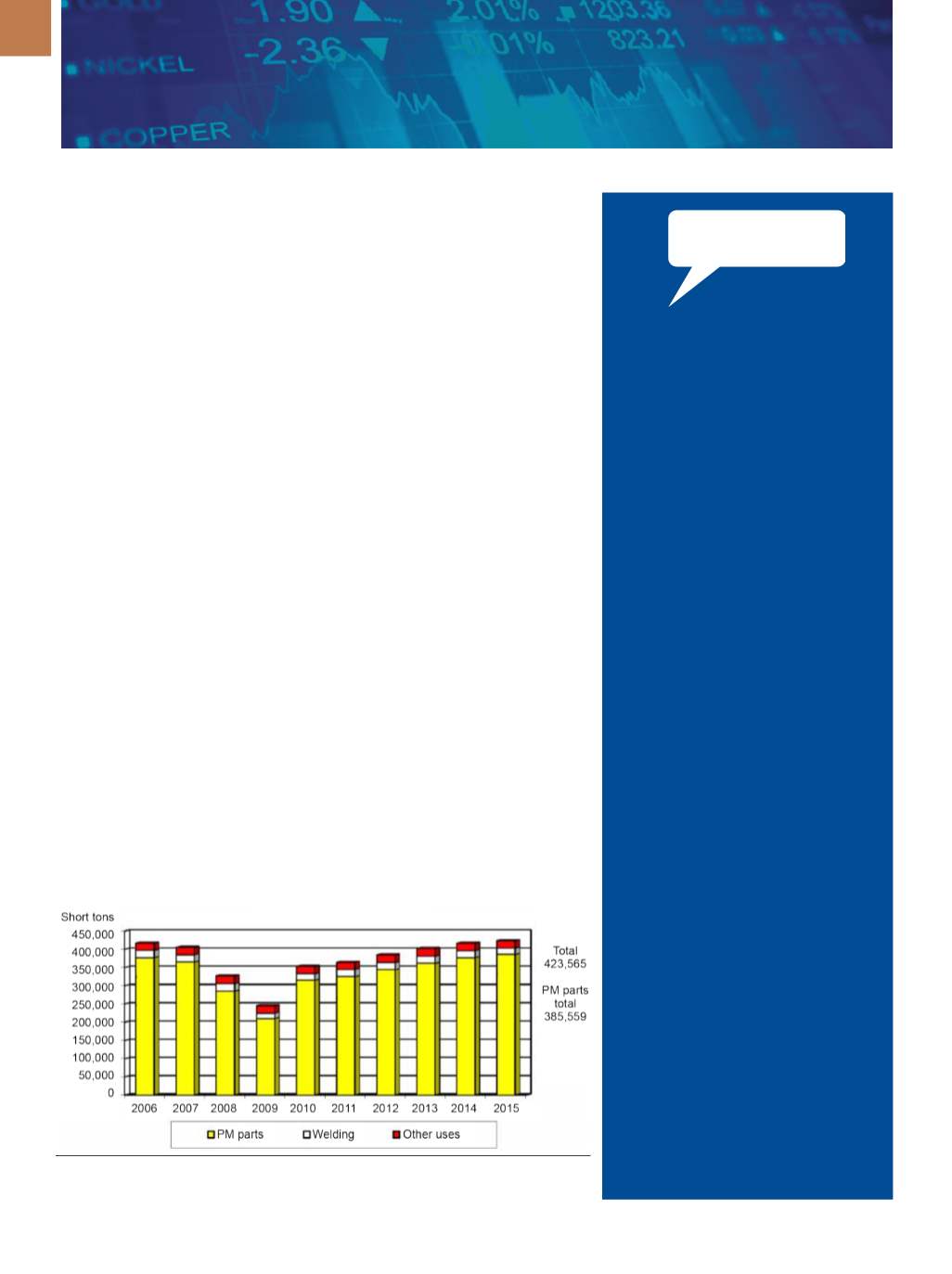

North American Iron Powder Shipments

Courtesy of Metal Powder Industries Federation.