A D V A N C E D M A T E R I A L S & P R O C E S S E S | S E P T E M B E R 2 0 1 6

1 4

SURFACE ENGINEERING

CORROSION-PROOF STEEL

A team from Swansea University,

UK, which is developing a new smart

release corrosion inhibitor for use in

coated steel products, is working on an

alternative to hexavalent chromate—a

common corrosion inhibitor facing an

EU ban in 2019. Corrosion inhibitors

are commonly used in a wide range of

sectors, including coated steel products

used to construct industrial, commer-

cial and other buildings; aerospace and

aircraft; and the automobile industry.

The device contains a stored res-

ervoir of corrosion inhibitor. It works

by channeling aggressive electrolyte

anions into the coating, triggering the

release of the inhibitor on demand, thus

preventing corrosion. “The system pre-

vents the onset of corrosion for over 24

hours compared to less than two hours

for the current market leader,” says

Professor Geraint Williams. “We have

demonstrated that the rate of corrosion

can be slowed down significantly once

it has started. This is by far the best

result seen in 15 years of research on

this topic.”

For more information: Ger-

aint Williams, geraint.williams@swan-

sea.ac.uk,

www.swansea.ac.uk.

GLAZING GLASS FOR

GREENER BUILDINGS

The amount of energy needed to

cool and ventilate all-glass buildings

can make them extremely heavy users

of resources—an expense that has

both ecological and economic conse-

quences. This is why glazing technolo-

gies play a critical role in the future of

glass manufacturing and sustainable

urban development.

In an effort to make all-glass build-

ings more sustainable and energy-effi-

cient, assistant professor of mechanical

and materials engineering Adel Gou-

gam of Masdar Institute, United Arab

Emirates, is leading a team that devel-

oped a low-cost glass coating that can

significantly reduce the amount of heat

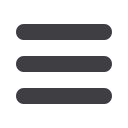

A steel panel with the new anti-

corrosion treatment after being

exposed to hundreds of hours of

salt spray shows virtually no signs

of corrosion. Courtesy of Patrick

Dodds, Swansea University.

The iconic Aldar Headquarters building

in Abu Dhabi has a panoramic glass

facade glazed with an energy efficient,

low emissivity coating.

that penetrates glass while minimizing

manufacturing costs.

The material used to make this

unique glass coating is metal oxide

based, which when coated on a glass

pane, lets in an ample amount of sun-

light while blocking solar infrared radi-

ation. This technique helps to maintain

a neutral and natural appearance at a

much lower manufacturing cost than

conventional coatings. “By avoiding

the need to repeat the vapor deposition

technique several times, we reduced

the complexity and energy requirement

of themanufacturing process, as well as

the manufacturing cost, contributing to

a more sustainable production process

and product,” says Gougam.

For more

information: Adel Gougam, agougam@

masdar.ac.ae,

www.masdar.ac.ae.

BRIEF

Pipe Restoration Technologies,

Las Vegas, was granted its 15th U.S. patent for the ePIPE epoxy coating system.

The system effectively and safely seals leaks and protects pipes from lead leaching. Pipes as small as 0.5 in. diameter

can be protected from lead leaching and restored by sealing leaks in-place using the minimally invasive technique.

aceduraflo.com.